Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

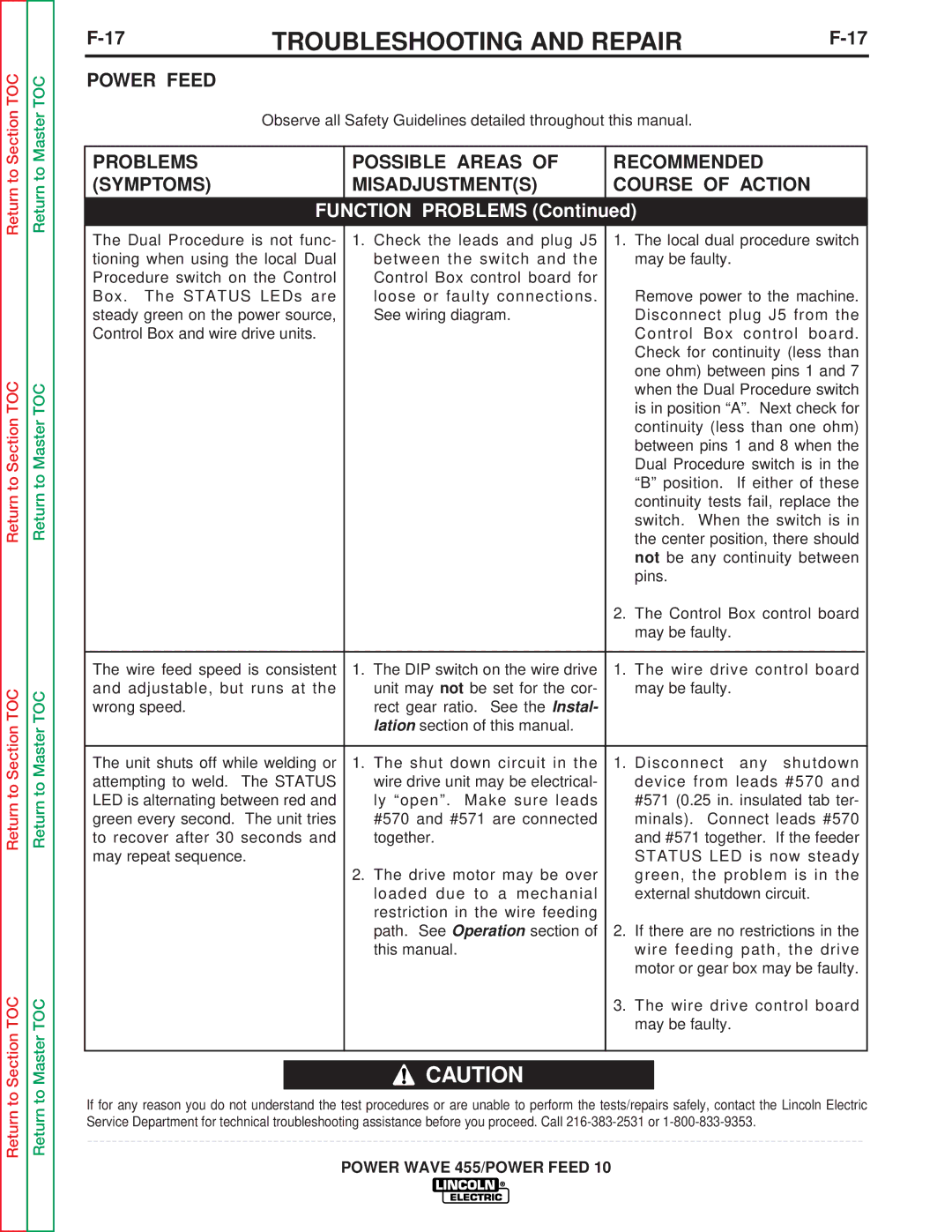

TROUBLESHOOTING AND REPAIR |

POWER FEED

Observe all Safety Guidelines detailed throughout this manual.

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION |

|

|

|

FUNCTION PROBLEMS (Continued) | ||

|

|

|

The Dual Procedure is not func- | 1. Check the leads and plug J5 | 1. The local dual procedure switch |

tioning when using the local Dual | between the switch and the | may be faulty. |

Procedure switch on the Control | Control Box control board for |

|

Box. The STATUS LEDs are | loose or faulty connections. | Remove power to the machine. |

steady green on the power source, | See wiring diagram. | Disconnect plug J5 from the |

Control Box and wire drive units. |

| Control Box control board. |

|

| Check for continuity (less than |

|

| one ohm) between pins 1 and 7 |

|

| when the Dual Procedure switch |

|

| is in position “A”. Next check for |

|

| continuity (less than one ohm) |

|

| between pins 1 and 8 when the |

|

| Dual Procedure switch is in the |

|

| “B” position. If either of these |

|

| continuity tests fail, replace the |

|

| switch. When the switch is in |

|

| the center position, there should |

|

| not be any continuity between |

|

| pins. |

|

| 2. The Control Box control board |

|

| may be faulty. |

|

|

|

The wire feed speed is consistent | 1. The DIP switch on the wire drive | 1. The wire drive control board |

and adjustable, but runs at the | unit may not be set for the cor- | may be faulty. |

wrong speed. | rect gear ratio. See the Instal- |

|

| lation section of this manual. |

|

|

|

|

The unit shuts off while welding or | 1. The shut down circuit in the | 1. Disconnect any shutdown |

attempting to weld. The STATUS | wire drive unit may be electrical- | device from leads #570 and |

LED is alternating between red and | ly “open”. Make sure leads | #571 (0.25 in. insulated tab ter- |

green every second. The unit tries | #570 and #571 are connected | minals). Connect leads #570 |

to recover after 30 seconds and | together. | and #571 together. If the feeder |

may repeat sequence. |

| STATUS LED is now steady |

| 2. The drive motor may be over | green, the problem is in the |

| loaded due to a mechanial | external shutdown circuit. |

| restriction in the wire feeding |

|

| path. See Operation section of | 2. If there are no restrictions in the |

| this manual. | wire feeding path, the drive |

|

| motor or gear box may be faulty. |

|

| 3. The wire drive control board |

|

| may be faulty. |

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call