Section TOC

Master TOC

THEORY OF OPERATION |

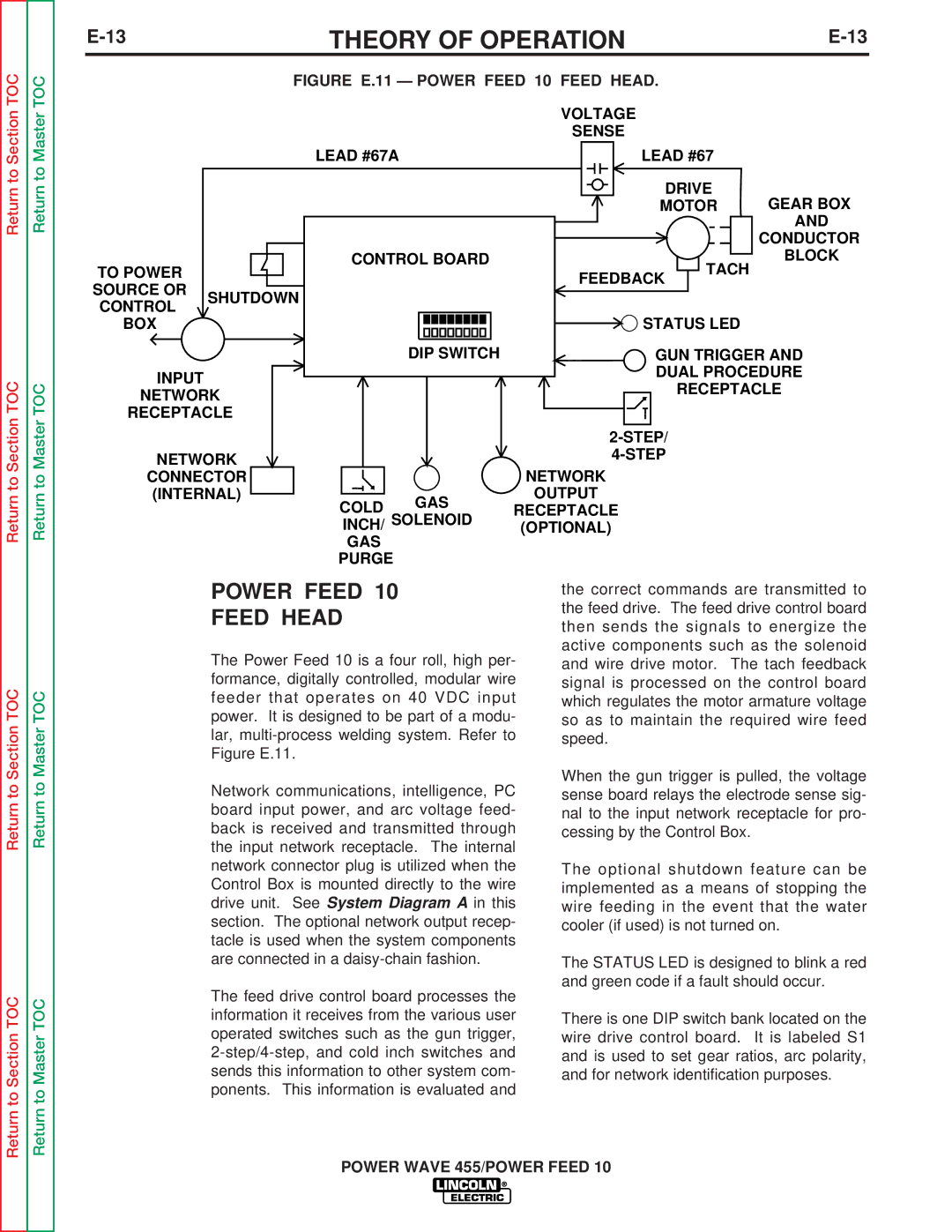

FIGURE E.11 — POWER FEED 10 FEED HEAD.

VOLTAGE

SENSE

Return to

Return to Master TOC

TO POWER |

| |

SOURCE OR | SHUTDOWN | |

CONTROL | ||

| ||

BOX |

| |

INPUT |

| |

NETWORK | ||

RECEPTACLE | ||

NETWORK

CONNECTOR

(INTERNAL)

LEAD #67A | LEAD #67 |

| |

|

| DRIVE | GEAR BOX |

| MOTOR | ||

|

|

| AND |

|

|

| CONDUCTOR |

CONTROL BOARD |

| TACH | BLOCK |

| FEEDBACK |

| |

|

|

| |

|

| STATUS LED | |

| DIP SWITCH | GUN TRIGGER AND | |

|

| DUAL PROCEDURE | |

|

| RECEPTACLE | |

|

|

| |

|

|

| |

|

| NETWORK | |

COLD | GAS | OUTPUT | |

RECEPTACLE | |||

| |||

INCH/ SOLENOID | (OPTIONAL) | ||

GAS |

|

| |

PURGE |

|

| |

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

POWER FEED 10

FEED HEAD

The Power Feed 10 is a four roll, high per- formance, digitally controlled, modular wire feeder that operates on 40 VDC input power. It is designed to be part of a modu- lar,

Network communications, intelligence, PC board input power, and arc voltage feed- back is received and transmitted through the input network receptacle. The internal network connector plug is utilized when the Control Box is mounted directly to the wire drive unit. See System Diagram A in this section. The optional network output recep- tacle is used when the system components are connected in a

The feed drive control board processes the information it receives from the various user operated switches such as the gun trigger,

the correct commands are transmitted to the feed drive. The feed drive control board then sends the signals to energize the active components such as the solenoid and wire drive motor. The tach feedback signal is processed on the control board which regulates the motor armature voltage so as to maintain the required wire feed speed.

When the gun trigger is pulled, the voltage sense board relays the electrode sense sig- nal to the input network receptacle for pro- cessing by the Control Box.

The optional shutdown feature can be implemented as a means of stopping the wire feeding in the event that the water cooler (if used) is not turned on.

The STATUS LED is designed to blink a red and green code if a fault should occur.

There is one DIP switch bank located on the wire drive control board. It is labeled S1 and is used to set gear ratios, arc polarity, and for network identification purposes.

POWER WAVE 455/POWER FEED 10