Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

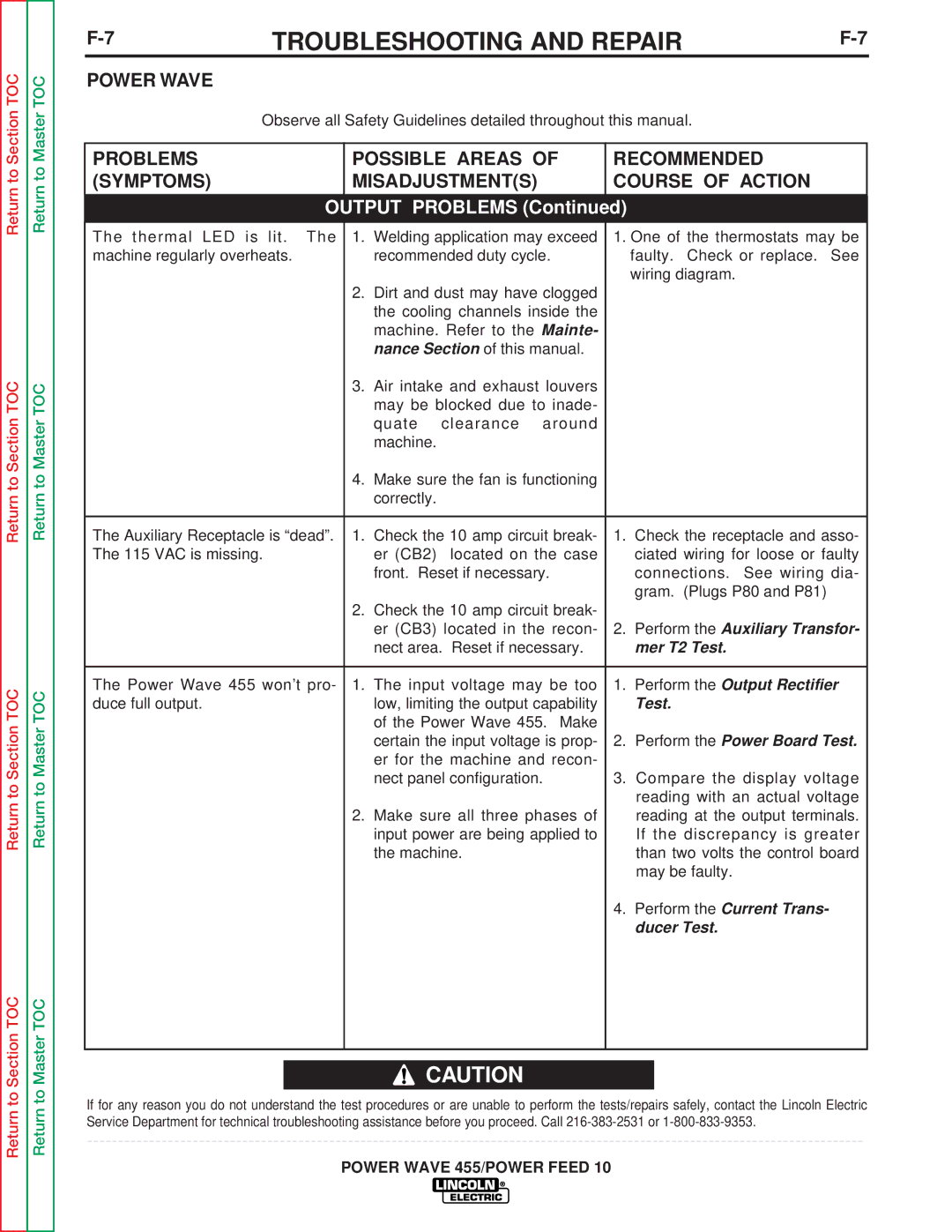

TROUBLESHOOTING AND REPAIR |

POWER WAVE

Observe all Safety Guidelines detailed throughout this manual.

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED | |||

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | |||

|

|

|

| ||

OUTPUT PROBLEMS (Continued) |

| ||||

|

|

|

|

|

|

The thermal LED is lit. The | 1. | Welding application may exceed | 1. One of the thermostats may be | ||

machine regularly overheats. |

| recommended duty cycle. |

| faulty. Check or replace. See | |

|

|

|

|

| wiring diagram. |

| 2. | Dirt and dust may have clogged |

|

| |

|

| the cooling channels inside the |

|

| |

|

| machine. Refer to the Mainte- |

|

| |

|

| nance Section of this manual. |

|

| |

| 3. | Air intake and exhaust louvers |

|

| |

|

| may be blocked due to inade- |

|

| |

|

| quate | clearance around |

|

|

|

| machine. |

|

|

|

| 4. | Make sure the fan is functioning |

|

| |

|

| correctly. |

|

|

|

|

|

|

|

| |

The Auxiliary Receptacle is “dead”. | 1. | Check the 10 amp circuit break- | 1. | Check the receptacle and asso- | |

The 115 VAC is missing. |

| er (CB2) | located on the case |

| ciated wiring for loose or faulty |

|

| front. Reset if necessary. |

| connections. See wiring dia- | |

|

|

|

|

| gram. (Plugs P80 and P81) |

| 2. | Check the 10 amp circuit break- |

|

| |

|

| er (CB3) located in the recon- | 2. | Perform the Auxiliary Transfor- | |

|

| nect area. Reset if necessary. |

| mer T2 Test. | |

|

|

|

| ||

The Power Wave 455 won’t pro- | 1. | The input voltage may be too | 1. Perform the Output Rectifier | ||

duce full output. |

| low, limiting the output capability |

| Test. | |

|

| of the Power Wave 455. Make |

|

| |

|

| certain the input voltage is prop- | 2. | Perform the Power Board Test. | |

|

| er for the machine and recon- |

|

| |

|

| nect panel configuration. | 3. Compare the display voltage | ||

|

|

|

|

| reading with an actual voltage |

| 2. | Make sure all three phases of |

| reading at the output terminals. | |

|

| input power are being applied to |

| If the discrepancy is greater | |

|

| the machine. |

| than two volts the control board | |

|

|

|

|

| may be faulty. |

|

|

|

| 4. Perform the Current Trans- | |

|

|

|

|

| ducer Test. |

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call