Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

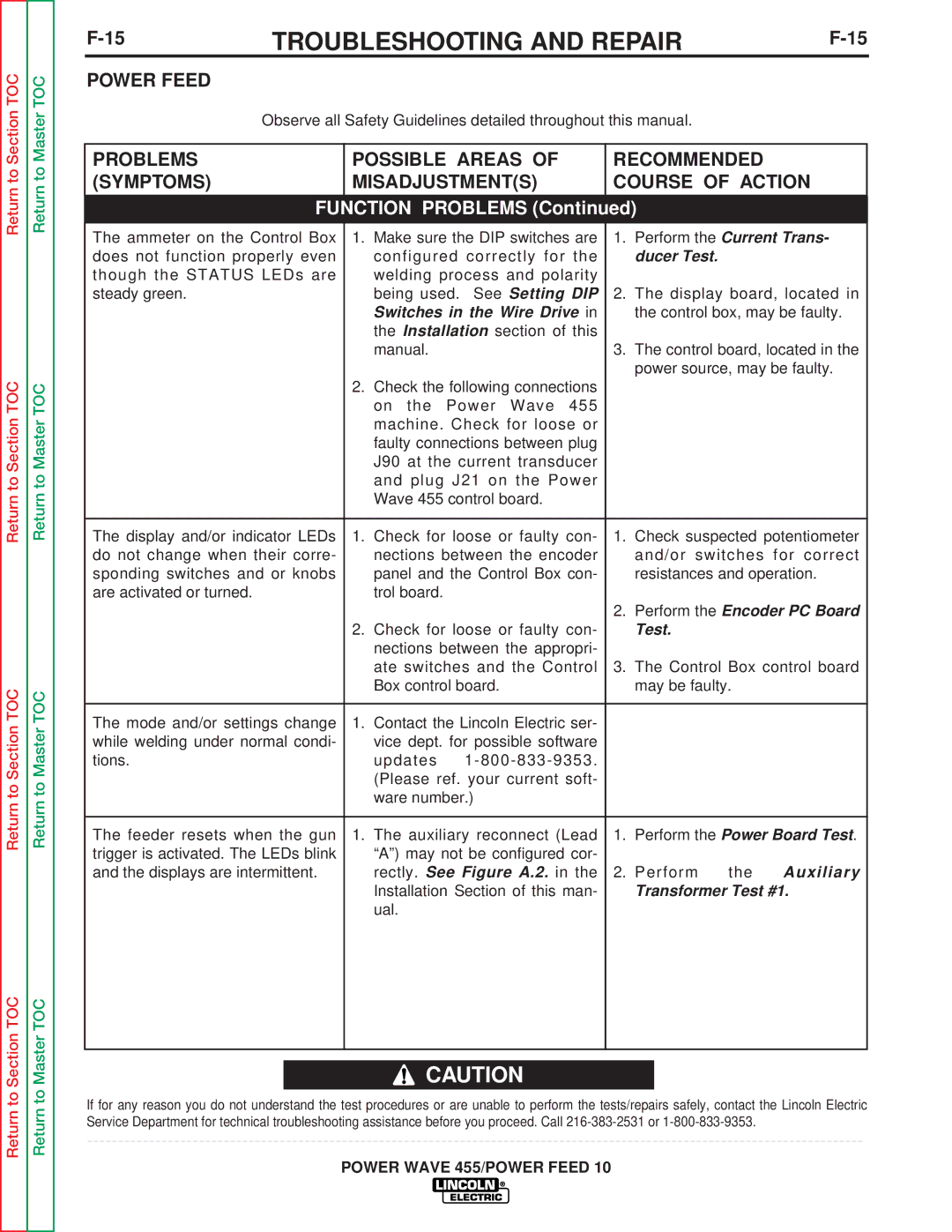

TROUBLESHOOTING AND REPAIR |

POWER FEED

Observe all Safety Guidelines detailed throughout this manual.

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

| ||

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | |||

|

|

|

|

| |

FUNCTION PROBLEMS (Continued) |

|

| |||

|

|

|

| ||

The ammeter on the Control Box | 1. Make sure the DIP switches are | 1. | Perform the Current Trans- | ||

does not function properly even | configured correctly for the |

| ducer Test. |

|

|

though the STATUS LEDs are | welding process and polarity |

|

|

|

|

steady green. | being used. See Setting DIP | 2. | The display board, located in | ||

| Switches in the Wire Drive in |

| the control box, may be faulty. | ||

| the Installation section of this |

|

|

|

|

| manual. | 3. | The control board, located in the | ||

|

|

| power source, may be faulty. | ||

| 2. Check the following connections |

|

|

|

|

| on the Power Wave 455 |

|

|

|

|

| machine. Check for loose or |

|

|

|

|

| faulty connections between plug |

|

|

|

|

| J90 at the current transducer |

|

|

|

|

| and plug J21 on the Power |

|

|

|

|

| Wave 455 control board. |

|

|

|

|

|

|

|

| ||

The display and/or indicator LEDs | 1. Check for loose or faulty con- | 1. | Check suspected potentiometer | ||

do not change when their corre- | nections between the encoder |

| and/or switches | for correct | |

sponding switches and or knobs | panel and the Control Box con- |

| resistances and operation. | ||

are activated or turned. | trol board. |

|

|

|

|

|

| 2. | Perform the Encoder PC Board | ||

| 2. Check for loose or faulty con- |

| Test. |

|

|

| nections between the appropri- |

|

|

|

|

| ate switches and the Control | 3. | The Control Box control board | ||

| Box control board. |

| may be faulty. |

| |

|

|

|

|

|

|

The mode and/or settings change | 1. Contact the Lincoln Electric ser- |

|

|

|

|

while welding under normal condi- | vice dept. for possible software |

|

|

|

|

tions. | updates |

|

|

|

|

| (Please ref. your current soft- |

|

|

|

|

| ware number.) |

|

|

|

|

|

|

|

| ||

The feeder resets when the gun | 1. The auxiliary reconnect (Lead | 1. | Perform the Power Board Test. | ||

trigger is activated. The LEDs blink | “A”) may not be configured cor- |

|

|

|

|

and the displays are intermittent. | rectly. See Figure A.2. in the | 2. | Perform | the | Auxiliary |

| Installation Section of this man- |

| Transformer Test #1. | ||

| ual. |

|

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call