Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

THEORY OF OPERATION |

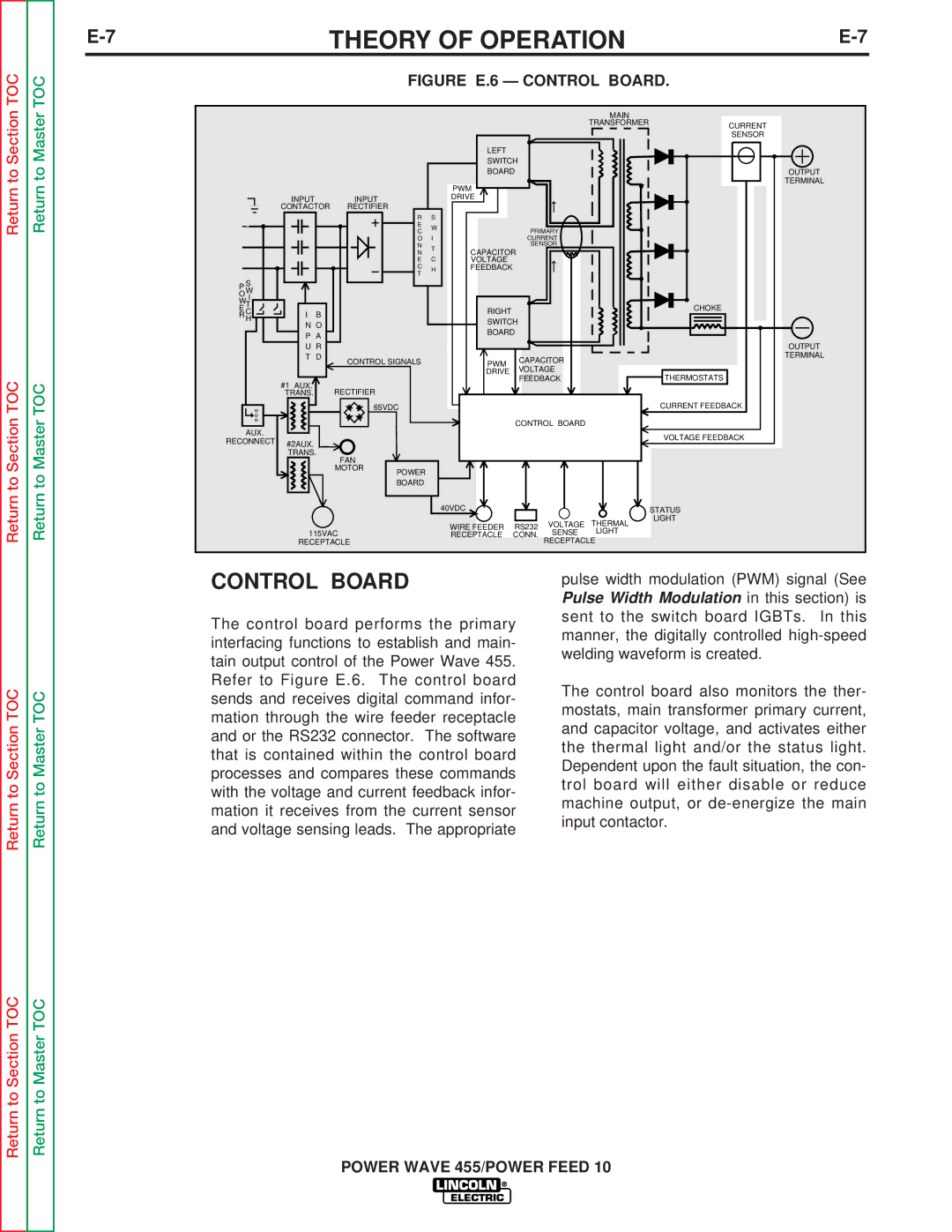

FIGURE E.6 — CONTROL BOARD.

|

|

|

|

|

|

|

|

| MAIN |

|

|

|

|

|

|

|

|

|

| TRANSFORMER | CURRENT |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| SENSOR |

|

|

|

|

|

| LEFT |

|

|

|

|

|

|

|

|

|

| SWITCH |

|

|

| |

|

|

|

|

|

| BOARD |

|

| OUTPUT | |

|

|

|

|

|

| PWM |

|

|

| TERMINAL |

|

|

|

|

|

|

|

|

|

| |

| INPUT |

| INPUT |

|

| DRIVE |

|

|

|

|

| CONTACTOR | RECTIFIER |

|

|

|

|

|

|

| |

|

|

|

| R | S |

|

|

|

|

|

|

|

|

| E | W |

|

|

|

|

|

|

|

|

| C |

| PRIMARY |

|

| ||

|

|

|

|

|

|

|

| |||

|

|

|

| O | I |

| CURRENT |

|

| |

|

|

|

| N | T |

| SENSOR |

|

| |

|

|

|

| N | CAPACITOR |

|

|

| ||

|

|

|

|

|

|

|

| |||

|

|

|

| E | C | VOLTAGE |

|

|

|

|

|

|

|

| C | H | FEEDBACK |

|

|

|

|

|

|

|

| T |

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| |

P S |

|

|

|

|

|

|

|

|

|

|

O W |

|

|

|

|

|

|

|

|

|

|

W I |

|

|

|

|

|

|

|

|

|

|

T |

|

|

|

|

| RIGHT |

|

|

| CHOKE |

E C | I | B |

|

|

|

|

|

| ||

R H |

|

|

| SWITCH |

|

|

| |||

| N O |

|

|

|

|

|

| |||

|

|

|

| BOARD |

|

|

| |||

| P A |

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| ||

| U R |

|

|

|

|

|

|

| OUTPUT | |

| T | D | CONTROL SIGNALS |

| PWM | CAPACITOR |

| TERMINAL | ||

|

|

|

|

|

| |||||

|

|

|

|

|

| DRIVE | VOLTAGE |

| THERMOSTATS | |

| #1 AUX. |

|

|

|

|

| FEEDBACK |

| ||

|

| RECTIFIER |

|

|

|

|

|

|

| |

| TRANS. |

|

|

|

|

|

|

|

| |

|

|

| 65VDC |

|

|

|

|

| CURRENT FEEDBACK | |

|

|

|

|

|

|

| CONTROL BOARD |

|

| |

AUX. |

|

|

|

|

|

|

|

|

| VOLTAGE FEEDBACK |

RECONNECT | #2AUX. |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| |

| TRANS. | FAN |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

|

| MOTOR | POWER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

| BOARD |

|

|

|

|

|

|

|

|

|

|

|

| 40VDC |

|

|

| STATUS |

|

|

|

|

|

| WIRE FEEDER | RS232 | VOLTAGE | THERMAL | LIGHT |

|

|

|

|

|

|

| ||||

| 115VAC |

|

| SENSE | LIGHT |

| ||||

|

|

| RECEPTACLE | CONN. |

| |||||

| RECEPTACLE |

|

|

|

| RECEPTACLE |

| |||

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

CONTROL BOARD

The control board performs the primary interfacing functions to establish and main- tain output control of the Power Wave 455. Refer to Figure E.6. The control board sends and receives digital command infor- mation through the wire feeder receptacle and or the RS232 connector. The software that is contained within the control board processes and compares these commands with the voltage and current feedback infor- mation it receives from the current sensor and voltage sensing leads. The appropriate

pulse width modulation (PWM) signal (See Pulse Width Modulation in this section) is sent to the switch board IGBTs. In this manner, the digitally controlled

The control board also monitors the ther- mostats, main transformer primary current, and capacitor voltage, and activates either the thermal light and/or the status light. Dependent upon the fault situation, the con- trol board will either disable or reduce machine output, or

POWER WAVE 455/POWER FEED 10