Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

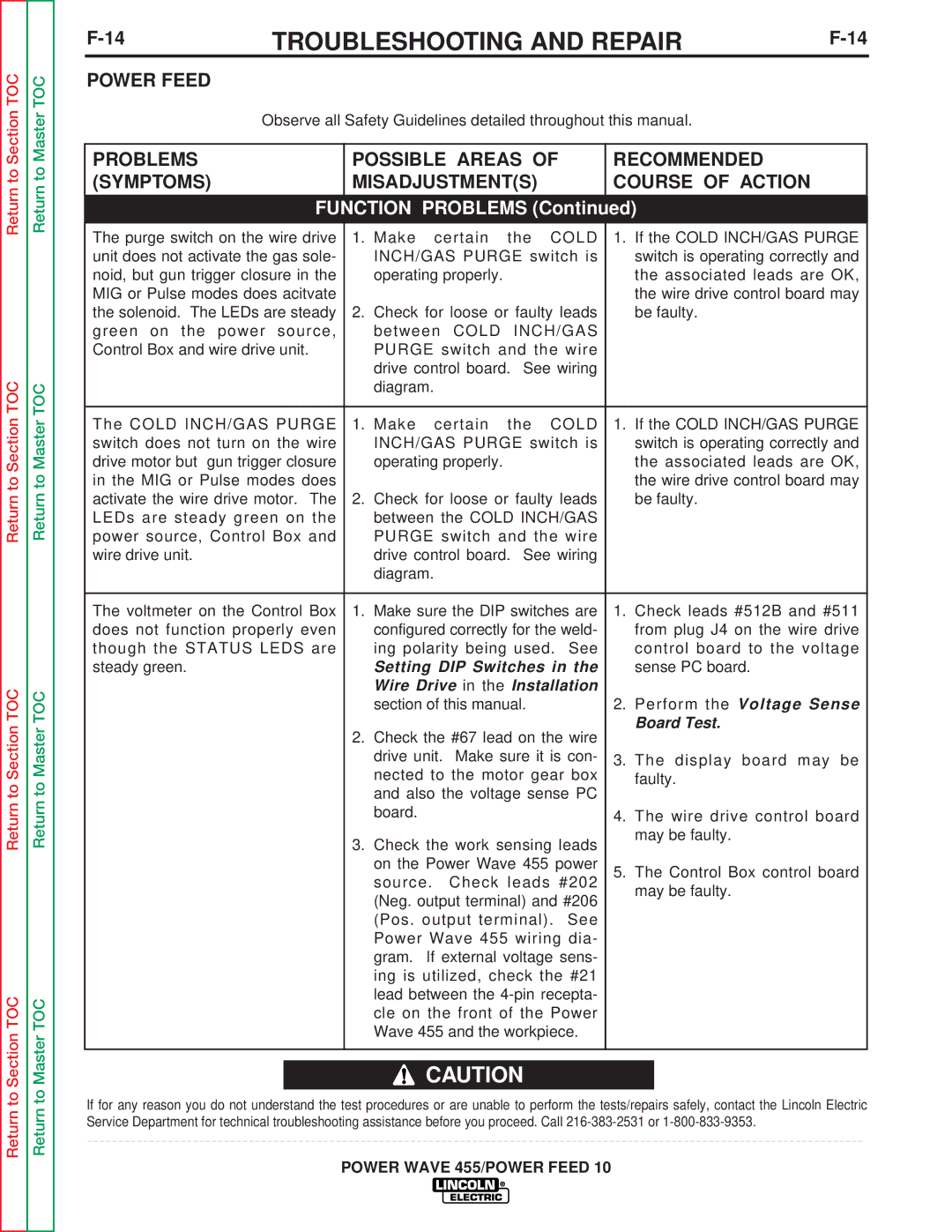

TROUBLESHOOTING AND REPAIR |

POWER FEED

Observe all Safety Guidelines detailed throughout this manual.

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED | |||

(SYMPTOMS) | MISADJUSTMENT(S) |

| COURSE OF ACTION | ||

|

|

| |||

FUNCTION PROBLEMS (Continued) | |||||

|

|

|

|

|

|

The purge switch on the wire drive | 1. Make | certain | the | COLD | 1. If the COLD INCH/GAS PURGE |

unit does not activate the gas sole- | INCH/GAS PURGE switch is | switch is operating correctly and | |||

noid, but gun trigger closure in the | operating properly. |

|

| the associated leads are OK, | |

MIG or Pulse modes does acitvate |

|

|

|

| the wire drive control board may |

the solenoid. The LEDs are steady | 2. Check for loose or faulty leads | be faulty. | |||

green on the power source, | between COLD | INCH/GAS |

| ||

Control Box and wire drive unit. | PURGE switch and the wire |

| |||

| drive control board. See wiring |

| |||

| diagram. |

|

|

|

|

|

|

|

|

|

|

The COLD INCH/GAS PURGE | 1. Make | certain | the | COLD | 1. If the COLD INCH/GAS PURGE |

switch does not turn on the wire | INCH/GAS PURGE switch is | switch is operating correctly and | |||

drive motor but gun trigger closure | operating properly. |

|

| the associated leads are OK, | |

in the MIG or Pulse modes does |

|

|

|

| the wire drive control board may |

activate the wire drive motor. The | 2. Check for loose or faulty leads | be faulty. | |||

LEDs are steady green on the | between the COLD INCH/GAS |

| |||

power source, Control Box and | PURGE switch and the wire |

| |||

wire drive unit. | drive control board. See wiring |

| |||

| diagram. |

|

|

|

|

|

|

| |||

The voltmeter on the Control Box | 1. Make sure the DIP switches are | 1. Check leads #512B and #511 | |||

does not function properly even | configured correctly for the weld- | from plug J4 on the wire drive | |||

though the STATUS LEDS are | ing polarity being used. See | control board to the voltage | |||

steady green. | Setting DIP Switches in the | sense PC board. | |||

| Wire Drive in the Installation |

| |||

| section of this manual. |

| 2. Perform the Voltage Sense | ||

| 2. Check the #67 lead on the wire | Board Test. | |||

|

| ||||

| drive unit. Make sure it is con- | 3. The display board may be | |||

| nected to the motor gear box | faulty. | |||

| and also the voltage sense PC |

| |||

| board. |

|

|

| 4. The wire drive control board |

| 3. Check the work sensing leads | may be faulty. | |||

|

| ||||

| on the Power Wave 455 power | 5. The Control Box control board | |||

| source. | Check leads #202 | |||

| may be faulty. | ||||

| (Neg. output terminal) and #206 | ||||

|

| ||||

| (Pos. output terminal). See |

| |||

| Power Wave 455 wiring dia- |

| |||

| gram. If external voltage sens- |

| |||

| ing is utilized, check the #21 |

| |||

| lead between the |

| |||

| cle on the front of the Power |

| |||

| Wave 455 and the workpiece. |

| |||

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call