Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

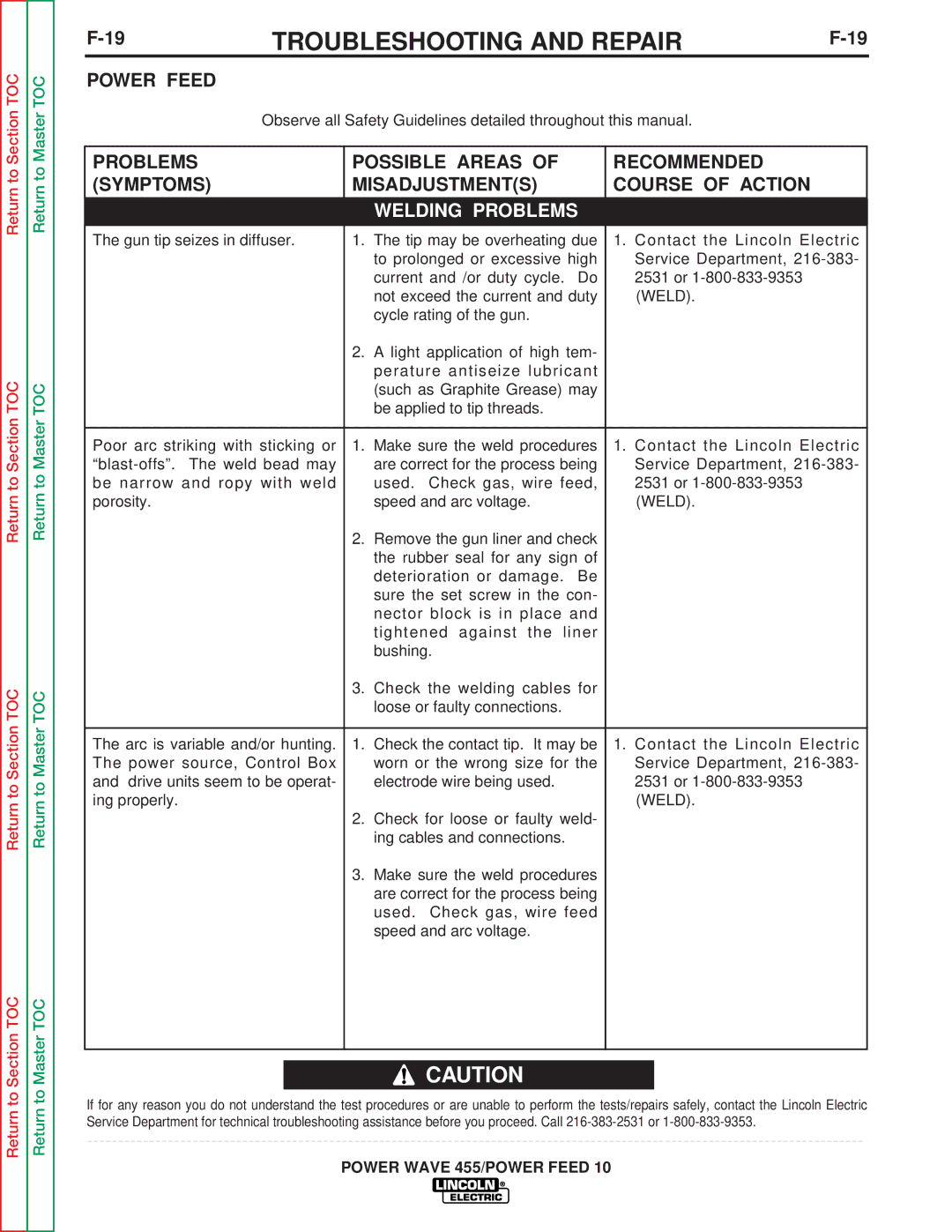

TROUBLESHOOTING AND REPAIR |

POWER FEED

Observe all Safety Guidelines detailed throughout this manual.

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED | |

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | |

|

|

|

|

|

| WELDING PROBLEMS |

|

|

|

|

|

The gun tip seizes in diffuser. | 1. | The tip may be overheating due | 1. Contact the Lincoln Electric |

|

| to prolonged or excessive high | Service Department, |

|

| current and /or duty cycle. Do | 2531 or |

|

| not exceed the current and duty | (WELD). |

|

| cycle rating of the gun. |

|

| 2. | A light application of high tem- |

|

|

| perature antiseize lubricant |

|

|

| (such as Graphite Grease) may |

|

|

| be applied to tip threads. |

|

|

|

|

|

Poor arc striking with sticking or | 1. | Make sure the weld procedures | 1. Contact the Lincoln Electric |

| are correct for the process being | Service Department, | |

be narrow and ropy with weld |

| used. Check gas, wire feed, | 2531 or |

porosity. |

| speed and arc voltage. | (WELD). |

| 2. | Remove the gun liner and check |

|

|

| the rubber seal for any sign of |

|

|

| deterioration or damage. Be |

|

|

| sure the set screw in the con- |

|

|

| nector block is in place and |

|

|

| tightened against the liner |

|

|

| bushing. |

|

| 3. | Check the welding cables for |

|

|

| loose or faulty connections. |

|

|

|

|

|

The arc is variable and/or hunting. | 1. | Check the contact tip. It may be | 1. Contact the Lincoln Electric |

The power source, Control Box |

| worn or the wrong size for the | Service Department, |

and drive units seem to be operat- |

| electrode wire being used. | 2531 or |

ing properly. |

|

| (WELD). |

| 2. | Check for loose or faulty weld- |

|

|

| ing cables and connections. |

|

| 3. | Make sure the weld procedures |

|

|

| are correct for the process being |

|

|

| used. Check gas, wire feed |

|

|

| speed and arc voltage. |

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call