SX4T Series, B-SX5T Series

Table of Contents

ATA Card Writable Character Information Acquire Command

Byte Writable Character Code Range Command

BIT MAP Writable Character Command ESC XD

BIT MAP Writable Character Command ESC XA

LCD Messages in Different Languages Upper Line of LCD

Scope

Page

Page

Model Type

Download Mode

Sdram

Memory Whole 32 MB × 1 = 32 MB

When the Snmp function is enabled 1.65 MB

B0H

EF-1M-TB AA D0H 1CH

MF81M1-GBDAT01

EF-4M-TB CC

Serial Interface

Interface

Page

Page

RTS

Input/Output Signals Printer

RTS CTS DSR DTR

CTS

RTS DTR

CTS DSR

Parallel Interface

57E-30360 or equivalent

DDK

57RE-40360-73B or equivalent

Cable Amp. Japan Or equivalent

Chassis GND

Page

Page

Page

XFlag Printer → Host z

NStrobe Host → Printer Busy Host ← Printer NAck

SPP

Compatibility mode SPP

ECP mode ECP

Windows95/98/Me WindowsNT4.0 Windows2000/XP

0DH 0AH

SOX STX

ETX EOT

3XH

Network Interface

USB Interface

KEY Operation Functions

System Mode Functions

Page

Page

TYPE1

None

OFF

SX4T OFF SX5T

Auto

SX4

SX5

SX704-RFID-U2-EU/US/CN/AU-R

Online Mode Functions

Download Mode Setting Function

Parameter Initial Value LAN enable/disable setting

Initialization

Transmission Sequence

Page

Label Issue Operation

Page

Outline of Commands

ESC

NUL

List of Commands

Batch Reset Command

Commands related to check Head Broken Dots Check Command

Commands related to display Message Display Command

Commands related to control Reset Command

Label Size SET Command ESC D

Commands for Creating Application

Labels

Tags

SX4T SX5T

SX4T

Page

Examples Labels Tags

Position Fine Adjust Command ESC AX

+3.0 mm

First print position home position after back feed

±9.9 mm

±50.0 mm

Page

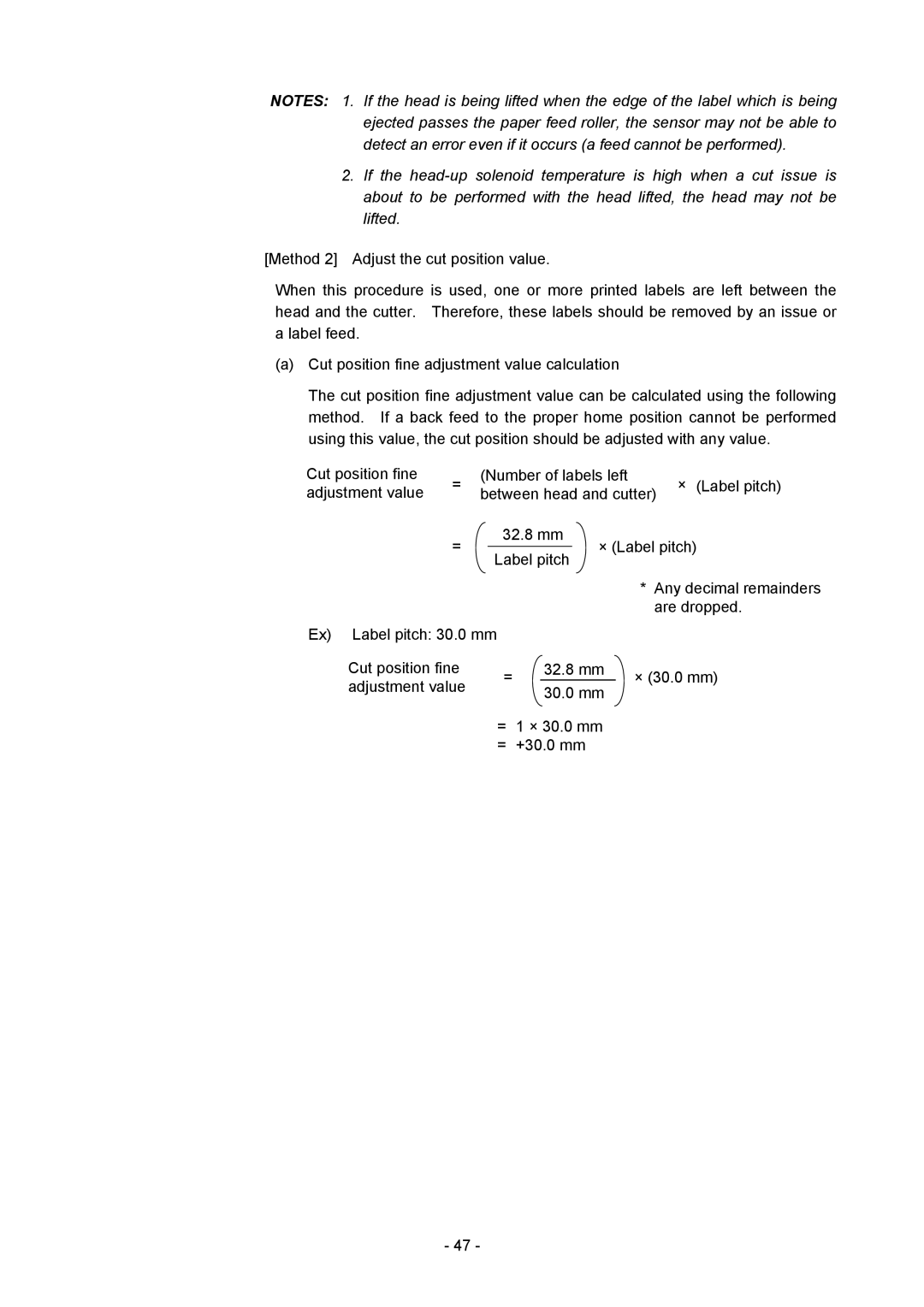

Operation example Issue count 2, Cut interval =

Page

Examples Cut issue

ESC AX +010, +020, +00 LF NUL

ESC T20D30 LF NUL

SX4T SX5T

Print Density Fine Adjust Command ESC AY

SX4T SX5T

Ribbon Motor Drive Voltage Fine Adjust Command ESC RM

Image Buffer Clear Command ESC C

Clear Area Command ESC XR

Effective print area

Line Format Command ESC LC

Line Horizontal line In the case of Y2 Y1 =

Vertical line In the case of X2 X1 =

Slant line a X 2 X 1 ≤ Y 2 Y Slant line B X 2 X 1 Y 2 Y

Radius of rounded corners ≠

1496.0 1492.0 Ips

Times Roman Medium Point Bold Italic Helvetica Presentation

BIT MAP Font Format Command ESC PC

Letter Gothic Medium Point Prestige Elite Bold Courier

OCR-A

OCR-B

Page

Page

Sample

Horizontal magnification and vertical magnification

OCR-A OCR-B

Relationship between drawing coordinates and magnification

180 270

Rotational angles of a character and character string

Black characters Reverse characters

Selection of character attribution

A2A0A

INC/DEC

A0A0A

A2A0A INC/DEC

Left Center

Alignment

Abcd

LF NUL Link field No is designated

Page

Page

C D

55.0 20.0 mm 65.0 mm Effective print area

ESC RC001

AB LF NUL

Outline Font Format Command ESC PV

Page

Designates the character position

Page

180 270

Origin Label

Character width and character height

Page

Page

Page

180 270 Selection of character attribution

A0A0A INC/DEC

Zero suppression 7A8/9 7A9/2 7A9/5 7A9/8 8A0/1

A2A0A A1A7A A1A4A A1A1A A0A8A

ABC

Page

Page

C D

30.0 55.0 20.0 mm 65.0 mm Effective print area

UPC-A

BAR Code Format Command ESC XB

KIX Code

CODE93

Postnet

WPC

CODE128 Pseudo

CODE128 Pseudo UCC/EAN128

Page

CODE39

MSI

ITF

Page

Page

Page

Page

Page

Page

Page

Parameter No. of columns No. of rows

Page

Page

Page

Page

Page

TID

Permanent lock

Page

Page

Page

Only tag ID is read

Rfid read mode Omissible

When omitted, only user data will be read

Only user data is read

XXH ETX

XXH

118

119

UPC-A + 2 digits

KIX code CP Code MaxiCode 120

Postnet RM4SCC

DataBar Omnidirectional GS1 DataBar Stacked

GS1

MSI ITF CODE39 NW7

JAN, EAN, UPC CODE93

180 270 123

Case of QR code

Bar code height

Postal code

124

Height of bar code Length of guard bar

Page

7A8/9 7A9/2 7A9/5 7A9/8 8A0/1

LF NUL Link field No is designated

ECC0

ECC50

ECC80

ECC0 ECC50 ECC80

Row Col

ECC200

Page

Cell width

Page

Page

Page

Page

Page

Origin 0 12.5

Origin 0

55.0 20.0 mm 83.0 mm

BIT MAP Font Data Command ESC RC

ABC

Sample

30.0

ESC XS I, 0002, 0002C3000 LF NUL 147

Outline Font Data Command ESC RV

Sample

30.0

BAR Code Data Command ESC RB

11 digits

Royal Mail 4 State Customer Code 12 digits

ECC0 ECC50 ECC80

ECC200

Sets the security level automatically

Parameter No. of columns No. of rows

Page

Page

Page

Transfer code for QR code

160

Examples

Origin 0

12.5

Issue Command ESC XS

Page

Head position

Cut position Head position

Cut position Head position

Cut position Head position

Cut position Head position

Strip mode Issue count

Strip position Head position

Strip position Head position

Rotary cutter

Ribbon saving area Printing area

175

Labels Tags 176

Labels Tags Printing top first

Labels Tags 177

Labels Tags Mirror printing top first

M p l e

Paper is moved in the above state

Stop position after feeding one label

179

Feed Command ESC T

Head position

Cut position Head position

Strip position Head position

Strip position Head position

SX4T SX5T

M p l e

ESC IB LF NUL

Eject Command ESC IB

Rotary cutter is used

ESC U1, ESC U2

FORWARD/REVERSE Feed Command

AAA

For the firmware before

Storage Area Allocate Command ESC XF

Page

Page

Page

ESC J1

Flash Memory Format Command

ATA Card Format Command ESC JA

21 2-BYTE Writable Character Code Range Command ESC XE

BIT MAP Writable Character Command For Flash Memory ESC XD

ESC XA

Page

= Writable character

Writable character set 01 to 40, 51 to

Hex. mode

Page

Writable character set 41 16×16 dots

Writable character set 42 24×24 dots

Hex. mode

Writable character set 43 32×32 dots

Writable character set 44 48×48 dots

Page

Examples Writable character set Writable character code 70H

Graphic Command ESC SG

Print origin Coordinates

Nibble mode

Not present Present

When Topix compression mode is selected

Data after being compressed Line No Graphic data

215

10.0 mm

Topix compression mode

ESC XP LF NUL

ESC XO

ECS

Save Terminate Command ESC XP

ESC XQ

ESC XT

Head Broken Dots Check Command ESC HD

Message Display Command ESC XJ

Issue 4 labels

Examples Load paper

225

ESC WR LF NUL

Reset Command ESC WR

ESC WS LF NUL

Status Request Command ESC WS

ESC WB LF NUL

Receive Buffer Free Space Status Request Command ESC WB

2EH

Version Information Acquire Command ESC WV

ESC WV LF NUL

2DH

ATA Card Information Acquire Command ESC WI

Names

Stored PC command save file name

File name including extension

00H should be placed between file

Character Storage

ESC WN LF NUL

Printer Option Status Acquire Command ESC WN

IP Address SET Command ESC IP

Socket Communication Port SET Command ESC is

Dhcp Function SET Command ESC IH

ESC @002

PASS-THROUGH Command

Internal Serial Interface Parameter SET Command ESC IZ

None Even

Commands for System Administrator

Parameter SET Command ESC Z2

LATIN9

English German French Dutch Spanish Japanese Italian

Reset process is performed

Web printer function is disabled

Web printer function is enabled

Reset process is not performed

Oracle

Fine Adjustment Value SET Command ESC Z2

Page

ESC Z2

Rfid Parameter SET Command

Auto

Batch Reset Command ESC Z0 zero

Explanation of the Rfid Related Commands

Rfid TAG Position Adjustment Command

Label Rfid Antenna 248

Page

Rfid TAG Read Command ESC WF

Page

OAH

01H Start of the status block

04H End of the status block

ODH

Read data

When a reading succeeded. When Rfid read mode=2

Read data Tag type ISO18000-6B

ABC···DEF

ESC @006

Rfid Void Pattern Print Command

ESC @012

Rfid Data Write Command

256

Unlocked Locked

When 0 Verification disabled is selected

259

260

Control Code Selection

Errors in Issuing or Feeding

Communication Errors

Page

Page

Errors in Writable Character and PC Command Save Modes

System Errors

Reset Processing

Rfid Error

Functions

Status Response

SOH STX

Status Format

Detail Status

An Eeprom for back up cannot be read/written Properly

Printer is waiting for a password to be entered

USB

Summary of Status Response

Compatibility Mode

Parallel Interface Signals

Printer cannot communicate with Rfid module

An Eeprom for back-up cannot be Read/written properly

274

Upper line Printer Status

275

Display of error

Yes Command

LCD Messages LED Indication

Rfid

Example 2 ESC T20 G30 LF NUL Command error LCD display

SX704-RFID-U2-US-R

Only

Blinking

English

LCD Messages in Different Languages Upper Line of LCD

279 No. Japanese

No. Spanish

280

Italian

Character Code Table

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

? O o

? O o

? O o

Page

? O o

Page

∝ ÷

Page

Page

Page

Page

Page

Page

Page

Page

ŠI ŠZ Â

DŠ Ô

Page

CŠ RŠ

Page

Page

Page

GB18030 Chinese Kanji 320

321

GB18030 code tables

322

323

324

PC-850 325

TrueType Font

PC-852 PC-857 326

PC-851 PC-855 327

PC-1250 PC-1251 328

PC-1252 10 PC-1253 329

11 PC-1254 12 PC-1257 330

LATIN9 Arabic 331

BAR Code Table

NW-7 CODE93 Transfer code Drawing code 357

CODE128 Transfer code

Start Code a Start Code B Start Code C

Drawing code Value Code Table 358

FNC4

102 FNC1 FNC1 FNC1

359

How to send control code data

00H 3EH, 40H

01H 3EH, 41H

NUL

NUL

363

01H 3EH 41H

00H @ 3EH 40H

Postnet RM4SCC KIX Code

Postal code Customer bar code

NUL

ESC 1BH and NUL 00H can be used as they are 367

FFH FFH, FFH

CP code Transfer Code

Transfer Code B C D E F

14 GS1 DataBar Expanded/GS1 DataBar Expanded Stacked

MOD79

MODE79

MOD89

Rfid Transfer Code

All codes can be used H to FFH How to send control code data

Modulus 10 check

Auto affix of modulus

372

373

Type of Bar Code JAN13, EAN13 No affix

Auto affix of modulus 10 + Price C/D 4 digits

Auto affix of modulus 10 + Price C/D 5 digits

374

Type of Bar Code UPC-A No affix

375

Type of Bar Code UPC-E No affix

376

Type of Bar Code JAN8 + 2 digits, EAN8 + 2 digits No affix

377

Type of Bar Code JAN8 + 5 digits, EAN8 + 5 digits No affix

Type of Bar Code JAN13 + 2 digits, EAN13 + 2 digits No affix

379

Type of Bar Code JAN13 + 5 digits, EAN13 + 5 digits No affix

Type of Bar Code UPC-A + 2 digits No affix

381

Type of Bar Code UPC-A + 5 digits No affix

382

Type of Bar Code UPC-E + 2 digits No affix

383

Type of Bar Code UPC-E + 5 digits No affix

IBM modulus 10 + Auto affix of IBM modulus

Type of Bar Code MSI No affix

IBM modulus 10 check

Auto affix of IBM modulus

Type of Bar Code Interleaved 2 No affix

Auto affix of DBP modulus

385

386

Type of Bar Code Industrial 2 No affix

Modulus check character check

Auto affix of modulus check character

Type of Bar Code CODE39 Standard No affix

Modulus 43 check

387

Type of Bar Code CODE39 Full Ascii No affix

Type of Bar Code NW7 No affix C/D check Auto affix

388

389

390

Type of Bar Code CODE93 No affix C/D check Auto affix of C/D

391

Type of Bar Code Postnet Auto affix of dedicated C/D

Type of Bar Code RM4SCC Auto affix of dedicated C/D

Type of Bar Code KIX Code No affix

CC7

392

Input Data Drawing Data

Automatic Adding of START/STOP Codes

12345ABC Standard Full Ascii