DesignJet 1050C/1055CM

Large-Format Printers

Safety Symbols

DesignJet 1050C/1055CM

Readership Part Numbers

Using this Manual

Purpose

Conventions

Table of Contents

System Error Codes

Service Tests and Utilities

Print Quality

Parts and Diagrams

Preventive Maintenance

Glossary Index

Table of Contents

Troubleshooting1

When reporting the System Error Code, make sure that you

Guide to Troubleshooting the Printer

Troubleshooting System Error Codes

Introduction

Performing a Service Test on a Failed Assembly

Performing the Necessary Service Calibrations

Solving Image Quality Problems

Troubleshooting

Printer does not Power on

ALL the Front-Panel LEDs are Lit but Nothing Else Happens

Line Sensor has Problems Detecting Media

Printer Continuously Rejects Printheads

Cover Sensors are not Working

Troubleshooting Media Jams/Printhead Crashes

Troubleshooting Shutdowns

Attempting any procedures to resolve the problem

Problem as explained as follows

Each case, make sure that you power OFF the printer before

Printhead Cleaner Path

Problems with the Vacuum Fan

Vacuum suction much lower at high altitudes

Bin marks on prints done on HP High Gloss media

Troubleshooting

HP-GL/2 color differences in different HP DesignJet Printers

Banding due to Ink Cartridge replacement while printing

Banding at variable extreme environmental conditions

Long term bleed and hue shift on HP High Gloss media

Media is causing the problem and not the Printer. Do not

Rice Paper not supported

Cut Sheet rice paper loading failure

Front Panel Keeps Indicating that Media Is Misaligned or

Solving Media-Handling Problems

Media may be loaded at an angle, causing the media to be

Incorrectly Positioned

Panel Menu

HP DesignJets 1050C

Image Quality

On, Off 7586, HP-GL/2

Utilities

Service Configuration Print

How to Print the Service Configuration Print

Press Enter

How to Use the Service Configuration Print

Sample of the Service Configuration Print

Troubleshooting

System Error Codes

System Error Codes

Continuable and Non-Continuable Error Codes

01002D Non-Continuable

Non-Continuable

Try the following

Calibrations Backup

Memory Dram Dimm Test failure

Make sure that you select Electronics Module Replaced when

010040

010042

ProblemError in Paper-axis Motor Encoder

EIO Accessories EIO Card/Hard Disk Drive Error

04Cxxx

One of the Printheads has an Internal Electrical Problem

060301

Problem with setting the Voltage of the Printheads

060309

06030B

09xxxx Non-Continuable

0A0000

Air Pressure is below the minimum requirement

0A0020

Error in Calibrating the APS Sensor

Problem in Depressurizing Air System

0A0030

0A0050 Non-Continuable

0A0070 Continuable

ProblemDrop Detector not Calibrated for all Printheads

System Error Codes During Initialization

0B0004

Unable to detect Pump

0B0007

Unable to detect Vacuum Fan

0B0009

Unable to detect Aerosol Fan Included on the Right Cover

0B000B

Pump or Pressure Sensor not working

HP No.80 Ink Supplies Troubleshooting

Printheads and Printhead Cleaners

What are HP No.80 Supplies?

Ink Cartridges

Identifying the Components

General Information About HP No.80 Supplies

Some General Precautions When Handling HP No.80 Supplies

When Should You Replace the HP No.80 Supplies?

Priming the Ink System

Show the Wrong Model message

Front Panel Display

Printing Monitor Quality

Obtaining Ink Cartridge Information

Ready

Obtaining Printhead Information

Cyan printhead info HP No.80 printhead

Ink Cartridge Status Messages

Ink Cartridge Status While Printing

Ink Cartridge Status While Replacing

Main actions for all 4 status messages is as follows

Printhead Status Messages While Printing

Refer to page 3-9,Obtaining Printhead Information

Carriage Assembly is faulty

Front panel displays Ready/Replace Draft Normal Best

Insert, it is possible that the Carriage Assembly is faulty

Printhead Status Messages While Replacing

Genuine HP No.80 Printhead

Summary of Solving HP No.80 Supplies Problems

Carriage during the priming process, they will be rejected

Front panel will show the Wrong Model message

Carriage Interconnect Wiper

This can damage the printhead and reduce print quality

Service Tests Utilities

Diagnostics Self Test

Introduction

Initialization Sequences

Must power OFF the Printer and Power on again before

Service Tests Diagnostics

Service Tests work in a special Mode which does not

Trying to print

Entering the Service Tests Menu

Order to enter the Service Utility Menu, please refer to

Instructions on

Electronic Systems

Make Selection

Electronics Failure

Dram Test Failure

You will be able to determine exactly which component failed

Carriage Test Failure

EIO Card

If this Test PASSES, do not Replace the EIO Card

Hard Disk Drive

Following message will appear on the front panel

Service Tests and Utilities

Check that the Hard Disk Drive is actually installed before

Test will of course always fail

Ink Pressure System

Tubes System Failure

APS Test Failure

Service Tests and Utilities Appear on the front panel

Scan Axis

Perform this test with the Printheads and the Tubes System

Max. PWM

Service Tests and Utilities

Paper Axis

Make sure you perform this test with no media loaded

Max PWM Avg PWM Max PWM C Avg PWM C

Drop Detector

Following step, make sure you do not drop the piece

Paper inside the Drop Detector

If this Test PASSES, do not Replace the Drop

Service Utilities

Entering the Service Utilities Menu

Enter Service Utilities again

Make sure that there is enough ink remaining in the Ink

New Tubes System has been installed

Tubes Purge

Enough ink remaining, you will get a warning message

Printer will then begin to purge the tubes system

Lift window to replace Setup printheads

Perform the Calibrations Backup ⇒ Page 5-19 in order to

Backup the Eerom Data from the Electronics Module. Make

Sure you select Tubes Replaced when performing

Release Info

Set Asian PS Fonts

Cancel

Printer Model Type

System and the Electronics Module have been replaced at

Same time

Printer model type selection done

Overdrive Cleaning

Roller and Roller Mark in order to clean them

Eerom Utilities

If you want to Test the Eerom

Displayed on the front panel

If you want to Clear the Eerom

Once the Eerom has been cleared, the following message will

Be displayed on the front panel

Printhead Check

Facility on or OFF

Make Selection

Mon. Mode Baud Sel

Default Baudrate for serial communication is

Change Baudrate

Service Calibrations

Service Calibrations

Refer to the following page for the relevant Calibration

Service Calibrations

This Calibration is no Longer Required

Entering the Service Calibrations Menu

You will not be able to access the Service Tools submenu

Service Calibrations

Accuracy Calibration

Media apart from HP High Gloss Photo Paper

Do not use any other type of media apart from HP High Gloss

Photo Paper

Measuring

Line Sensor

Make sure you load HP Coated media in to the Printer before

Performing this calibration

Calibrating line sensor Please wait

Service Station

Apart from HP Coated or HP High Gloss Photo Paper

Press Enter to continue

Roller Mark Position

Make sure that you unload the media from the Printer before

Roller mark position calibrated Press Enter to continue

Service Calibrations

Pen to Paper Spacing

Use any other type of media apart from HP Coated or HP High

Color to Color calibration

Make sure that you load E/A0 size HP High Gloss Photo Paper

Gloss Photo Paper

Make sure that you press Form Feed and Cut when you have

From HP Coated or HP High Gloss Photo Paper

Media roll

If the calibration pattern is bad

Calibrations Backup

If the Electronics Module was replaced

If the Tubes System was replaced

Tubes System Has been replaced?

Pen Alignment

Make sure you load media before performing this calibration

Do not use Clear Film, Vellum or Natural Tracing Paper

Do not use Clear Film, Vellum or Natural Tracing Paper

Carriage Height Calibration

Procedure should be carried out using the Carriage Height

Assembly or Center Platen Assembly

Tool See below that came with the new Carriage

Assembly has to be moved along the length of the printer for

With the carriage itself See below

Service Calibrations

Service Calibrations

Service Calibrations

Service Calibrations

Service Calibrations

Service Calibrations

Service Calibrations

Print Quality

Print Quality Troubleshooting Checklist

Print Quality

Photo Paper when performing the Accuracy Calibration

Print Modes

Considerations for Printing the Print Quality Test

How to Use the Print Quality Test

What is the Print Quality Test?

Printing the Print Quality Test

Utilities Test Prints

Nozzle Print Test

Print Quality

How to fix the Nozzle Defects

Color Alignment Print Test

Affects mostly Normal and Draft modes

Solving the Color Alignment Problem

Overall Print Quality Test in Best mode

What is Banding?

Solving the Banding Problem

Test pattern in all the primary and secondary color columns

Service Accuracy Calibration

Aligning the Printheads

Troubleshooting Print Quality Problems

Problems with Stepped Lines

Problems with printing lines

Problems with Color-to-Color Alignment

Print Quality Go to the Printer submenu and press Enter

Problems with Horizontal Lines Banding

Go to the printer submenu and press Enter

Accuracy Recalibrate

Possible combinations with this problem are

What to Configure

No Printing Defects Found in the Print Quality Test

Solving Color Accuracy problems

Color Consistency problems

Long Term Color Bleeding Glossy Papers

Color Accuracy Configuration

Setting Description Selection

To the User’s Guide or the Media Guide for the HP Designjet

Media

There are Smears or Scratching on the Printed Media

Printers

Parts and Diagrams

Printer Support

Printer Support

Rear Covers

Rear Covers

Electronics Module

Dram Dimm 64MB

Electronics Module

Right Hand Cover

Right Hand Cover

Left Hand Cover and Window

Left Hand Cover and Window

Right Hand Assemblies

Right Hand Assembly

ISS and APS Assembly

Ink Supply Station

Clutch Assembly

Clutch Assembly

Carriage Assembly

Carriage Assembly

Scan-Axis Assemblies

Scan-Axis Assemblies

Drive Roller and Arss Miscellaneous Parts

Items 1 and 3 are not orderable separately. These parts are

Drive Roller and Arss Miscellaneous Parts

Paper Path Assemblies

Paper Path Assemblies

Pinch Assembly

Pinch Assembly

Drive Roller Assemblies

Drive Roller Assemblies

Center Guide and Media Sensor

Center Guide and Media Sensor

Tubes Guide Assemblies

SRK Tubes Guide Assemblies

Ordering Accessories

Quick Reference Guide

Color Printheads and Printhead Cleaners

Parts and Diagrams

Removal and Installation

Safety Precautions

Introduction

Electrostatic Discharge ESD Precautions

Required Tools

Right Hand Cover

Removal

Right Cover

Front Panel Assembly

Installation of the Right Hand Cover

Right Hand Trim and Window Switch

Service Station Assembly

Service Station ⇒ Color to Color Calibration ⇒

Drop Detector Assembly

Drop Detector Assembly

Switch off the printer and remove the power cord

Vacuum Fan

Paper-axis Motor Assembly

Installation of the Paper-Axis Motor Assembly

You must perform the Accuracy Calibration ⇒ Page 5-6 after

Left Hand Cover

Left Hand Cover

Tube Grip

Ink Cartridge Tube Connector pulled back

Air Tube

Been removed

Remove the left hand cover item 3 from the printer

Left Hand Trim Assembly

Left Hand Trim

Ink Supply Station Assembly ISS

Working from the rear of the printer

Installation of the Air Pressurization System APS

Air Pressurization System APS

From steps 2 to 5, refer to Figure

Clutch Assembly and left hand miscellaneous parts

Next step the assembly is spring loaded and when

One hand to avoid loosing parts

For the following steps, refer to Figure

Tail Deflectors and Rear Platen

Left and Right Rear Covers

Be very careful when disconnecting the Trailing Cable from

For steps 2 to 7, refer to Figure

Cable and then it will need replacing

For the following steps, refer to Figure

When reconnecting the Trailing Cable to the Electronics

Installation of the Electronics Module

Removal and Installation

Module, make sure you connect it correctly as follows

After the installation of the Electronics Module

Media Sensor

Window

Window

Top Cover

Top Cover

Back Cover

Back Cover

Scan-axisMotor Assembly

Scan-axis Motor Assembly

Encoder Strip

Encoder Strip

For steps 4 and 5, refer to Figure

Clip item 2 in towards the middle of the printer

C607411

Tensioner Assembly

Tensioner

For steps 4 to 6, refer to Figure

Trailing Cable

For steps 2 to 5, refer to Figure

Installation of the Trailing Cable

C607440

Cutter Assembly

Cutter Assembly

For steps 3 and 4, refer to Figure

Carriage Assembly and Belt

Carriage Assembly and Belt

For steps 3 and 4, refer to Figure

For steps 6 to 8, refer to Figure

C607415

For steps 11 and 12, refer to Figure

For steps 13 to 15, refer to Figure

Rear bushing item 1 on the carriage assembly is tensioned

With a spring item 2. When removing the carriage assembly

Item 3 hold the rear bushing on the carriage assembly

Installation of the Carriage Assembly

Please take note of the following steps when installing

You must perform the following Service Calibrations after

Installation of the Carriage Assembly

Tubes System Assembly

Printhead Tube Connector Removal

Working from the rear of the printer

Latches

Ink Cartridge Tube Connector Cable

Ink Cartridge Tube Connector pulled out

Restarting the printer

Ink Leak Detector Assembly

Leak Detector Cable

Front Platen Assembly

Platen Assembly

Installation of the Platen Assembly

Paper Entry Assembly

Entry Roller

Linkage Rod

Roller Guide

Platen Mounts

Left Electronic Module Mount

For the following steps refer to Figure

Media Holder Strip

Media Holder Strip

Installation of the Drive Roller

Drive Roller

Center Guide

Left Hand Center Guide Screws

For re-installation purposes, note the position of the pins

Supporting the center guide in place

Working from the front of the printer

Pinch-Wheel Assembly and Cam

Pinch Wheel Cam

Assemblies item 2 to the underneath of the scan axis

For steps 3 and 4 refer to Figure

Remove the twelve T-15 screws item 1 securing the pinch-arm

Screws also secure the pinch-wheel cam to the printer

Preventive Maintenance

Preventive Maintenance

Cleaning the Overdrive

Scheduled Maintenance

Level of Printer Usage

Preventive Maintenance Kit Part Number C6072-60143

Scan-axis Maintenance

Maintenance Advised

Most important parts to keep clean are the upper

Functional Overview

HP DesignJet 1050C Printer

HP DesignJet 1055CM printer

Electrical System

Power Supply Unit PSU

Voltage Maximum Output Systems

Soft Power-Off Switch

Printer Cancel and Form Feed and Cut

Front Panel

Ink Delivery System IDS

Ink Supply Station ISS

Tubes System

Air Pressurization System APS

Ink Level Sense ILS

Leak Detect System LDS

Service Station

Print Head Cleaner PHC

Cap

Wiper

Spittoon

Snout Wiper

Handle and Printable Label

Printer Specifications

Functional Specifications

10-13

Temperature it may stop to protect its ink systems

At 3000m altitude the printer may have operational problems

10-15

Printable Area

Ansi paper

Interface Specifications

For manufacturing purposes only and cannot be used to print

Electro-Magnetic Compatibility EMC

To Obtain a Material Safety Data Sheet Msds Sound

Regulatory Notices

LpA 70 dB, am Arbeitsplatz, im Normalbetrieb, nach DIN

FCC How to Identify and Resolve Radio-TV Interference

10-20

10-21

Declaration of Conformity

10-23

10-24

Application

Default

Ansi size

Centronics

Inked area Matte

Margin

Input/output

Media

Platen

Raster

Pen

Printing area

Glossary

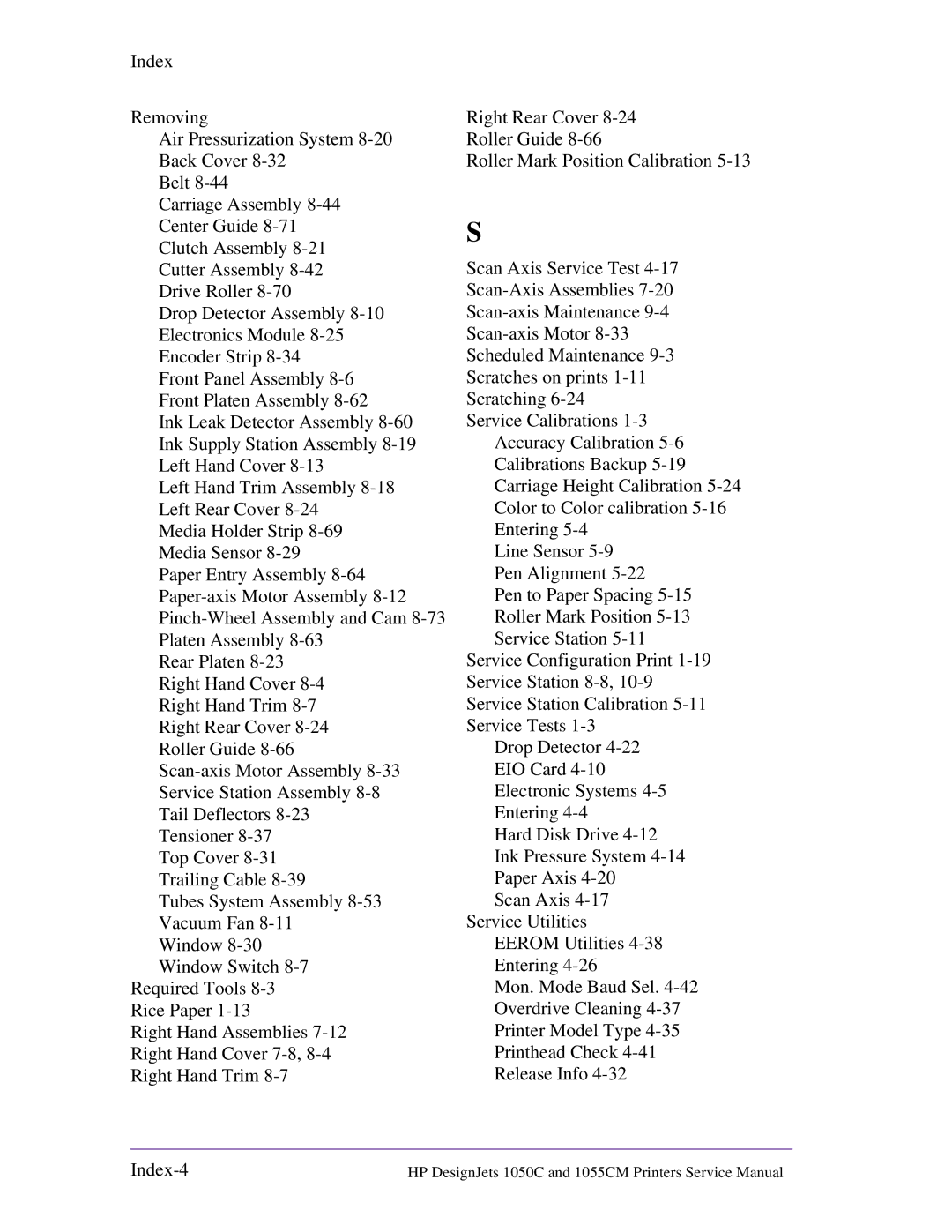

Index

Page

Page

Page

Page

Index Index-6

About this Edition

DesignJet 1050C/1055CM