Operating Manual

Page

Operating Manual for

Phone 604 422 Toll Free North America 800 667 Fax 604 421

How do you get service?

What does this warranty cover and how long does it last?

What will Xantrex do?

What does this warranty not cover?

Disclaimer Product

Release Release 3.0

Information About Your Power Supply

Model Number Serial Number Purchased From Purchase Date

Power Supply Safety

Manual

Symbols Used in This

Unit complies with Canadian EMC requirements of ICES-001

Approvals CE Mark

CSA C22.2 No

FCC Part 15 Radio Frequency Devices Class a Limits

Who Should Use This Manual Navigation Sections

About This Manual

About This Manual

Revisions

Contents

Operation

Contents

Remote Operation

Contents

Appendix A. Calibration

Current Sharing 6000 Watt only

Appendix C. Error Messages

Appendix B. Scpi Command Reference

Appendix D. Gpib

Appendix E. Specifications and Characteristics

Index

List of Tables

List of Tables

List of Figures

List of Figures

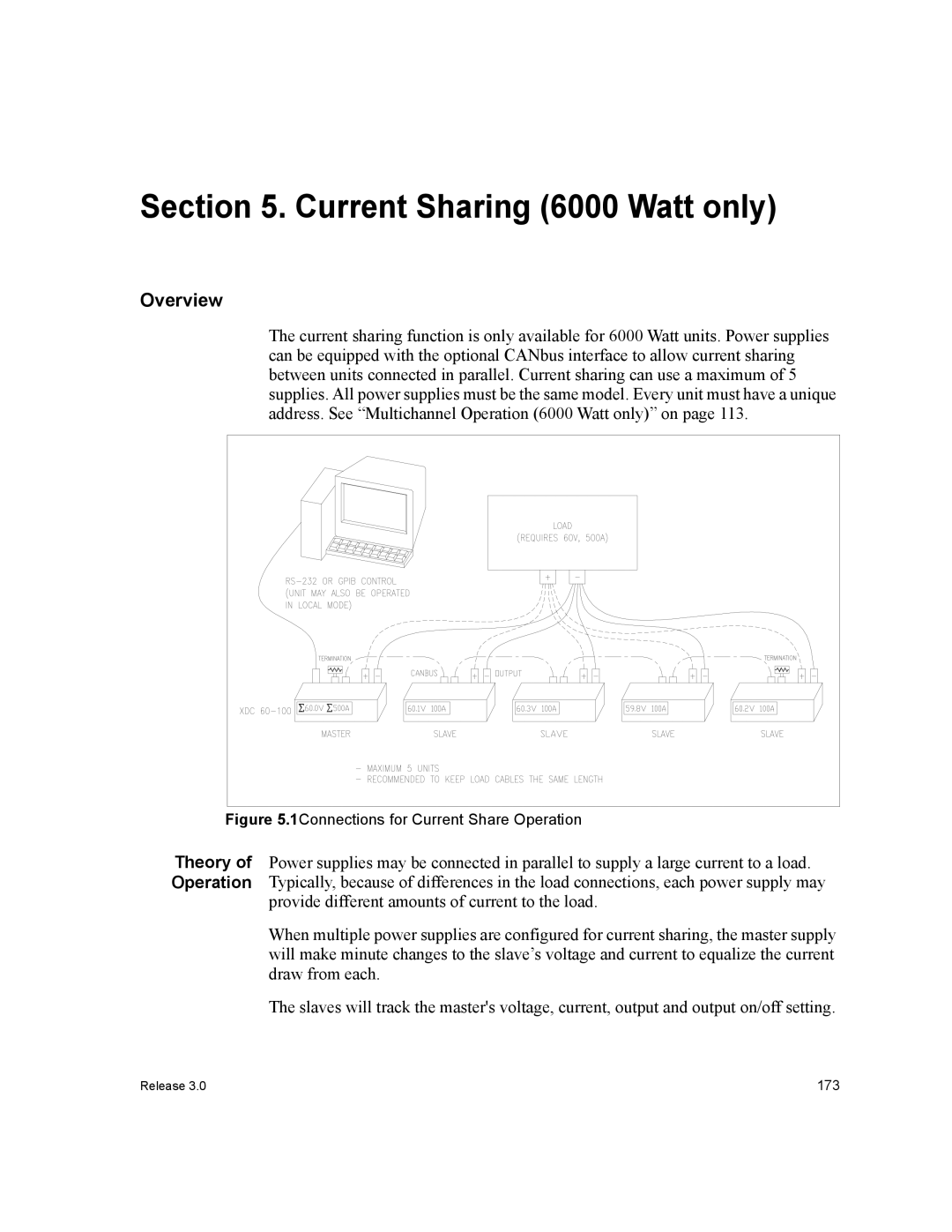

Overview

About The XDC Power Supply

Front Panel

About The XDC Power Supply

Front Panel 6000 Watt

Front Panel 12000 Watt

Keypad

About The XDC Power Supply

Special Key Functions

Key Functions

Menu Function

Front Panel Display, Status Annunciators

Display

Status Annunciators

Front Panel Display

Status Annunciators

Rear Panel 6000 Watt low and medium output shown

Rear Panel

Overview of Operation

About The XDC Power Supply

Basic Setup Procedure

Initial

Inspection, Cleaning, and Packaging

Inspection

Returning Power Supplies to the Manufacturer

Typical Box Label for Storage

Packaging for Shipping or Storage

Location, Mounting, and Ventilation

To install the power supply in an equipment rack

Rack Mounting

Unpacking the Power Supply 6000 Watt shown

Installation

AC Input Connector for 6000 Watt units

AC Input Power

AC Wire Specification for 6000 Watt units

AC Wire Input Connection For 6000 W

AC Input Voltage Range Wire

Attaching the AC Input Wires for 6000 Watt units

AC Wire Input Connection for 12000 W

Attaching the AC Input Wires for 12000 Watt units

Equipment Required

Basic Checks or Self-Tests

Power on Check

Voltage Mode Operation Check

Current Mode Operation Check

Wire Size Maximum Current a

Load Wiring

Installation

Load Connections

Installation

Multiple Loads

Fastening the Output Wires 6000 Watt Low and Medium Voltage

Output Strain Relief/Cover

Installation

11Output for 12000 Watt units High Voltage

Remote Sensing

Operation

Powering on Supply

Do This You Will See

Power Supply Operating States

Powering OFF Power Supply

Operation

Power Supply Regulation Modes

Remote Control Modes

LCL/RMT, OUT ON/OFF, VOLTAGE, and Current keys

Front Panel Controls

This output can be changed while the output is OFF

Operation

Operation

New voltage setpoint

Power Supply Operation

This saves the setting and enables

Step # Do This You Will See

Turn Output On or Off Set Output Protection

This saves the value and enables

New power setpoint

Press 8 times

Operation

Use the Voltage knob, the numeric

This setting is saved and the display

Returns to its default operating mode

To set the Over-Voltage Protection

If trip? N

These 2 extra steps are shown in the following example

To set the Under-Voltage Protection

To set the Over-Current Protection

Knobs, or the numeric keypad, or

To set the Over-Power Protection

To set the Under-Current Protection

Use both the Current and Voltage

UPP SET ####W

To set the Under-Power Protection

To set Fold Protection

Set Shutdown Recovery for AC Off

ACO AutoRecov3

To set both OTP and AC Off to Auto-Recovery

OTP is set to Auto Recovery

Times

Possible alarms are

Local/Remote

To shift from local to remote control

Shutdown vs Protection Alarm

Toggle

To change the remote control source

Select Remote Control Source

RS-232

Remote Control Prompt Configuration Settings Source

Configure Remote Control Source

To create and save a user setting

Set 1 unused

Settings

Set #####V

Set #####A

To restore the last setting

To retrieve a setting using Recall

To select a factory setting

To select a stored user setting

To select Auto Sequence

Feature Factory Preset Value

Settings Affected by Recall

Press repeatedly until all

To read and clear error messages

Messages have been read Cleared

To select which Aux line B

To access and work with the User Lines menu option

Line to configure

None

To configure Aux line B

Aux line B has been selected to be configured

Configure Power on Settings

Operating mode

To select Factory Preset

Factory Preset

Enter to select, or Default display for the selected

Last Setting

To select User Setting

To select Last Setting

User Setting

Auto Seq

Sequence sequence

Auto-Sequence

Auto Sequence

Sequence To program a sequence

Setting step advance by time

Use the scroll

Setting step advance by trigger

Keys to select the Wait for Trig Option

Sequence

This option allows you to delete an entire sequence

To delete a sequence

Deleting a

Edit Step

Editing a Sequence Step

To edit a step in a programmed sequence

Times or

Insert Step

Inserting a Sequence Step

To insert a step into a programmed sequence

Step #

Step ##

Deleting a Sequence Step

To delete a step in a programmed sequence

Step ## Deleted

Run Once

Editing Repeat Times Sequence

To edit the sequence’s repeat times

Set Repeat #

Trig From Man

To edit the sequence’s trigger sourceUsing Auto Sequencing

Editing Trigger Source of a Sequence

Trig Source

To run an auto sequence program

Voltage operates as RUN/PAUSE Current operates as Trigger

To lock out both knobs

Current knob is not locked out

This setting is saved, and the display

To lock out only the Voltage knob

Voltage knob is locked out

To set the voltage limits

To set the current limits

Use the Voltage and Current knobs

To set the power limit

Power Limit

High #####W

To set the slew rate

Xantrex

Default Display

To access and work with the View Model Information option

Time

Remote Operation

Remote Operation

Ieee 488.2 common commands that are supported are

View of Remote Interface Connections

Making Connections for Remote Control

Pin # Function Input/Output

User Line Pins

Remote Analog Operation

Pin Connections

Analog Programming Pins

Schematic For User Line Interface

Remote Interlock Using a Contact Closure

First, configure the analog programming lines

Front Panel

Select desired option

Where Is the 0-5V range, and 10 is the 0-10V range

To put the unit into remote control

To select the voltage level

112

CANbus

Multichannel Operation 6000 Watt only

Pin #

To receive and execute commands

Multichannel

Using

Changing REM/LCL modes and calibration

Connections for Multichannel Operation

STATOPERRCONCOND?

Will set all units in a multichannel string to 10.0

Specifications

Pin # Function

Configuration Front Panel

RS-232 Operation

First set the RS-232 parameters

Select flow control

Next, select RS-232 as the remote control interface

Select RS-232 to be the remote control source

Set the band rate

Gpib Operation

Gpib Pins

Select Gpib

Next, select Gpib as the remote control interface

Gpib setting is saved

First set the Gpib parameters

Where Gpib address may be in the range 1 to

To set up Gpib control parameters

To select Gpib as the remote control source

Response should be PRES, which stands for PRESet

Scpi Commands for Digital Interfaces

To power on factory settings

To check the current user setting

To reset to user setting #1

To power on the last stored setting

To power on user setting #1

To check the setting

Table below

Power on

To change the power on at output state

To reset the unit

Feature Reset State *RST

Features Affected by Reset *RST Command

To recall last settings

To store save settings

To recall settings

To save default settings

Program V,I,P Scpi

Change Remote/Local Control Power Supply

To set limits

To check a triggered setpoint

To check ranges

Configure V PProtection Limits

To set the Under-Power Protection level

To set the Over-Power Protection level

To check the Over-Power Protection level

To check if the Over-Power Protection was tripped

Fold Protection

Configure Other Protection Mechanisms

To set the fold mode

To set the fold delay

AC Off Protection

Over Temperature Protection

To query if OTP has tripped

To query if AC Off has tripped

Clear

View Power Supply Output Configure Auxiliary Status Lines

Event

To check the state of the line

To set up Auxiliary line B

Read Error To read from the error queue

To set the polarity of the auxiliary status lines

TRIGgerSOURce Busextimmnone Where

To program triggers

Editing

Programming Select Sequence to Program

Setting Sequence Repetitions

Editing the Sequence

Deleting Sequences

You can also use the following to delete all sequences

Selecting a Trigger Source

Editing Step Parameters

Skipping a Step

Auto Sequence Operation

Running

Trigger

Voltslewstep 1, Voltslewint 100ms

Status Registers

Option Identification Query

May return Xantrex, XDC 60-100, 100000, 3.000/0/0/0000

Transition Filters

Enable Register

OPERation Status Register

STATusOPERationREGulating

Operation Status Registers

OPERation Status Register

Bit Bit Weight Bit Name Description

Bit Name Description

REGulating Sub-Register

SHUTdown Sub-Register

Bit

Protection SHUTdown Sub-Register

Remote CONtrol Sub-Register

12 Protection SHUTdown Sub-Register

Current SHare Sub-Register

QUEStionable Status Register

Questionable Status Registers

Time

15 QUEStionable Status Register

VOLTage Sub-Register

POWer Sub-Register

CURRent Sub-Register

Ieee 488.2 Status Register and Status Byte

TEMPerature Sub-Register

19 TEMPerature Sub-Register

Standard Event Status Register

See Command Error List on

Been lost. See Query Error List on

Device-Specific Error List on

Condition. See Execution Error List on

Register

Error/Event Queue ERR

Status Byte

21 Status Byte Summary Register

Standard Event Status Summary ESB

Request Service RQS

Questionable Status Register Summary QSR

Message Available MAV

22 Preset Values of User Configurable Registers

Commands

Preset Status

Scpi Status Commands

Scpi equivalent for multichannel use

Ieee 488.2 Status and Event Commands

Command *SRE Service-Request-Enable, *SRE?

SYSTemchannelPOSClear ONOFF01 SYSTemchannelPOSClear?

Command *OPC, *OPC?

Scpi command STATuschannelOPERationCONDition?

Scpi command

Operation Status Register Commands

Scpi command STATuschannelOPERationEVENt?

STATuschannelOPERationREGulatingCONDition?

Regulating Sub-Register Commands

STATuschannelOPERationSHUTdownPTRansition?

Shutdown Sub-Register Commands

Protection Shutdown Sub-Register Commands

STATuschannelOPERationSHUTdownPROTectionENABle?

STATuschannelOPERationRCONtrolCONDition?

Remote Control Sub-Register Commands

STATuschannelOPERationCSHareCONDition?

Current Share Sub-Register Commands

Questionable Status Register Commands

STATuschannelQUEStionableENABle?

STATuschannelQUEStionableVOLTageCONDition?

Voltage Sub-Register Commands

STATuschannelQUEStionableCURRentCONDition?

Current Sub-Register Commands

Power Sub-Register Commands

STATuschannelQUEStionablePOWerENABle?

Temperature Sub-Register Commands

Temperature Event Sub-Register is read and then cleared

172

Current Sharing 6000 Watt only

Press 7 times

Configure Current Share

No sharing

Current Sharing 6000 Watt only

Setup Current Sharing Network

Operation

177

178

Appendix A. Calibration

Entering Calibration Mode

Front Panel To access calibration mode via the front panel

Code ####

Output Cal Change Code

You are back in the Calibration menu. Output V Cal

Setup and Equipment

Output Voltage

Front Panel Calibration Procedure

Power supply will set the output voltage to 90%

Output Current

Analog Programming Interface Range

Power supply will set the output to 90%

Analog Programming Interface Current Programming Calibration

Analog Programming Interface Voltage Readback Calibration

Analog Programming Interface Current Readback Calibration

Enter the voltage read from the external DVM. Press Enter

Set the output current to 10% by sending the command

Remote Interface Calibration Procedure

Set the output voltage to 10% by sending the command

Set the output voltage to 90% by sending the command

CALANAL5VPROGVOLTLEV MAX

Set the output current to 90% by sending the command

CALANAL5VREADVOLTLEV MIN

CALANAL5VPROGCURRLEV MAX

CALANAL10V

Output V Cal

Exit calibration mode

Restore Factory Calibration

Restore? Y

Codes and Standards

Appendix B. Scpi Command Reference

Parameters Units of Measure and Multipliers

Scpi Command Hierarchy

Scpi Command Reference

IEEE-488.2/SCPI Syntax and Style

Is the same as typing

Using Scpi Commands

CALibrationCURRentLEVel currentMINMAX

CALCURRentLEVel currentMINMAX

Using Minimum Maximum Queries

OPC *PSC Off *TRG

Voltprot voltageMAXMIN

Parameter Types

Calstat on

Notations

Scpi Command Summary

Tables

Scpi Command

Table B.1IEEE 488.2 Commands

200

Table B.2Readback Commands

Table B.3Commands for Output Control

202

Table B.4Commands for Current Share 6000 W only

Table B.6Command to Clear all Protection Mechanisms

Table B.5Commands for Calibration

Table B.8Commands for Triggering

Table B.7Commands for Fold Protection

Table B.9System Commands

Table B.10Status Commands

206

207

208

Table B.12User Lines

Table B.11Protection Commands

Table B.13Output State

PROGramchannelSELectedSTEPNEXT

Table B.14Auto Sequence Commands

211

Legacy Command

Table B.15Legacy Commands

Expression Details

Expressions

Expressions

Appendix C. Error Messages

Errorcode Error Message Description

Command Error List

Execution Error List

Error Messages

Execution Error List

Error Error Message Description Code

Device-Specific Error List

User Request Event

Query Error List

Operation Complete Event

Auto Sequencing Error Codes

Front Panel Error Codes

CPU Error Codes

Analog Programming Interface Error codes

Multichannel Error Codes

CANbus Error Codes

Current Share Error Codes

Address

Service Request and Polling

Message Terminators

Address Range

Function Mnemonic Description Functions Subset

Protocol Specifications

Control Functions

Interface Ieee 488.1 Section

Driver Ieee 488.2 Section

Electrical Specifications

Mechanical Specifications

Performance Specifications

Performance Specifications

Appendix E. Specifications and Characteristics

Specifications and Characteristics

Electrical Specifications-Summary

229

Models 80-75 100-60 150-40 300-20 600-10

231

Models 10-1200 20-600 30-400 40-300 60-200

233

Models 80-150 100-120 150-80 300-40 600-20

235

Arms 12000 Watt

AC Line Input Specifications

AC Line Input Voltage Operating Ranges

Arms 6000 Watt

103% of maximum rated voltage

Output Performance Specifications

Readback Accuracy

Typical Programming Resolution

Typical Measurement Resolution

Programming Accuracy1

Analog Programming Interface

Hour Drift Temperature Stability2

Temperature Coefficients

Minute Drift1

Maximum Within regulation envelope

Typical 31 kHz 62 kHz output ripple

To 95% step in output voltage

For a programmed 95% to 5% step in output voltage

Minimum 3.8 V for each line, 5 V typical

Maximum deviation as a percentage of rated output voltage

International Approvals

Environmental Specification

Humidity Specification

Specification

Figure E.1 Power Supply Dimensions 6000 Watt unit

Mechanical Specification

Figure E.2 Power Supply Dimensions 12000 Watt unit

Index

Gpib

247

248

249

250

Page

Xantrex Technology Inc