and PM

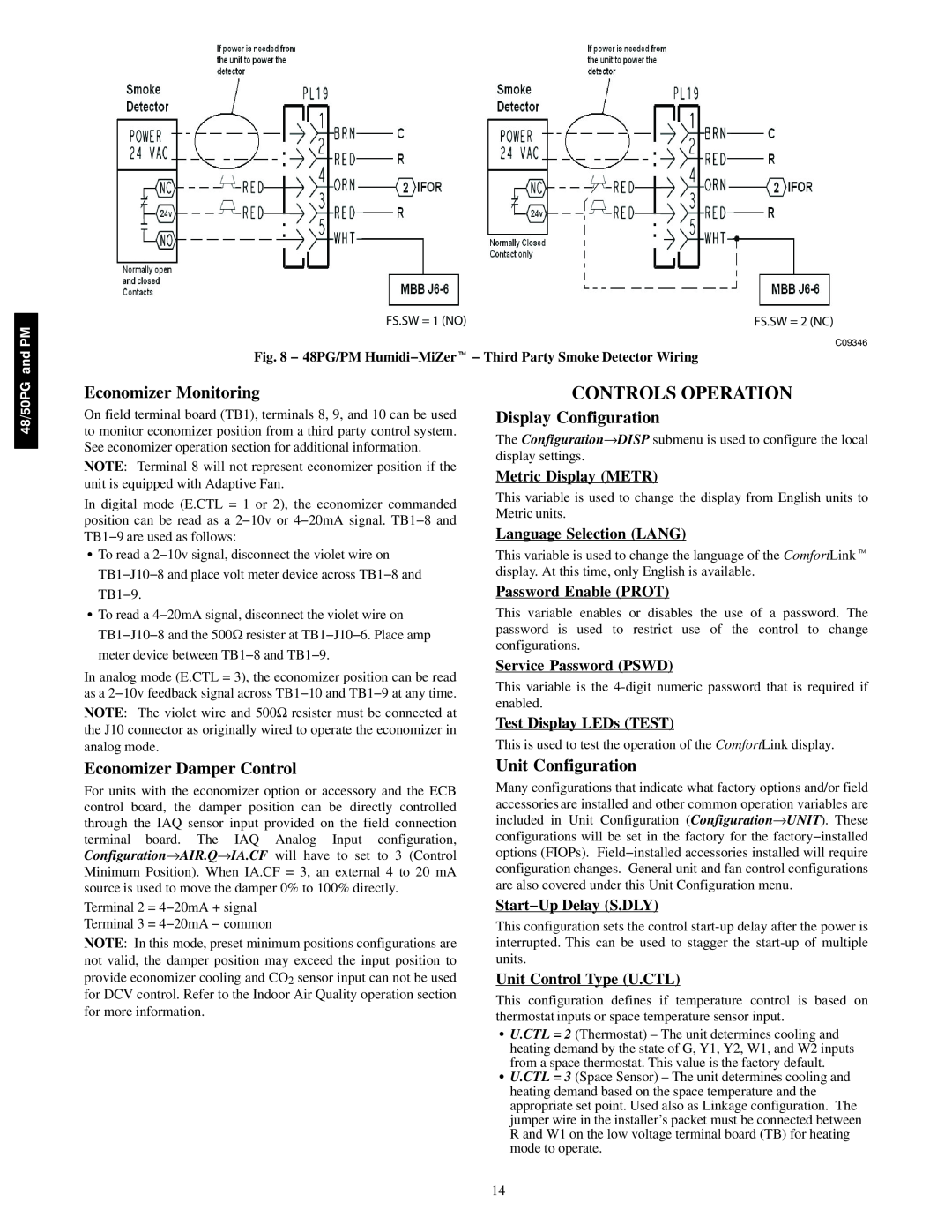

FS.SW = 1 (NO) | FS.SW = 2 (NC) |

C09346

Fig. 8 − 48PG/PM Humidi−MiZert − Third Party Smoke Detector Wiring

48/50PG

Economizer Monitoring

On field terminal board (TB1), terminals 8, 9, and 10 can be used to monitor economizer position from a third party control system. See economizer operation section for additional information.

NOTE: Terminal 8 will not represent economizer position if the unit is equipped with Adaptive Fan.

In digital mode (E.CTL = 1 or 2), the economizer commanded position can be read as a 2−10v or 4−20mA signal. TB1−8 and TB1−9 are used as follows:

STo read a 2−10v signal, disconnect the violet wire on

TB1−J10−8 and place volt meter device across TB1−8 and TB1−9.

STo read a 4−20mA signal, disconnect the violet wire on TB1−J10−8 and the 500Ω resister at TB1−J10−6. Place amp

meter device between TB1−8 and TB1−9.

In analog mode (E.CTL = 3), the economizer position can be read as a 2−10v feedback signal across TB1−10 and TB1−9 at any time.

NOTE: The violet wire and 500Ω resister must be connected at the J10 connector as originally wired to operate the economizer in analog mode.

CONTROLS OPERATION

Display Configuration

The Configuration→DISP submenu is used to configure the local display settings.

Metric Display (METR)

This variable is used to change the display from English units to Metric units.

Language Selection (LANG)

This variable is used to change the language of the ComfortLinkt display. At this time, only English is available.

Password Enable (PROT)

This variable enables or disables the use of a password. The password is used to restrict use of the control to change configurations.

Service Password (PSWD)

This variable is the

Test Display LEDs (TEST)

This is used to test the operation of the ComfortLink display.

Economizer Damper Control

For units with the economizer option or accessory and the ECB control board, the damper position can be directly controlled through the IAQ sensor input provided on the field connection terminal board. The IAQ Analog Input configuration, Configuration→AIR.Q→IA.CF will have to set to 3 (Control Minimum Position). When IA.CF = 3, an external 4 to 20 mA source is used to move the damper 0% to 100% directly.

Terminal 2 = 4−20mA + signal Terminal 3 = 4−20mA − common

NOTE: In this mode, preset minimum positions configurations are not valid, the damper position may exceed the input position to provide economizer cooling and CO2 sensor input can not be used for DCV control. Refer to the Indoor Air Quality operation section for more information.

Unit Configuration

Many configurations that indicate what factory options and/or field accessories are installed and other common operation variables are included in Unit Configuration (Configuration→UNIT). These configurations will be set in the factory for the factory−installed options (FIOPs). Field−installed accessories installed will require configuration changes. General unit and fan control configurations are also covered under this Unit Configuration menu.

Start−Up Delay (S.DLY)

This configuration sets the control

Unit Control Type (U.CTL)

This configuration defines if temperature control is based on thermostat inputs or space temperature sensor input.

SU.CTL = 2 (Thermostat) – The unit determines cooling and heating demand by the state of G, Y1, Y2, W1, and W2 inputs from a space thermostat. This value is the factory default.

SU.CTL = 3 (Space Sensor) – The unit determines cooling and heating demand based on the space temperature and the appropriate set point. Used also as Linkage configuration. The jumper wire in the installer’s packet must be connected between R and W1 on the low voltage terminal board (TB) for heating mode to operate.

14