48/50PG and PM

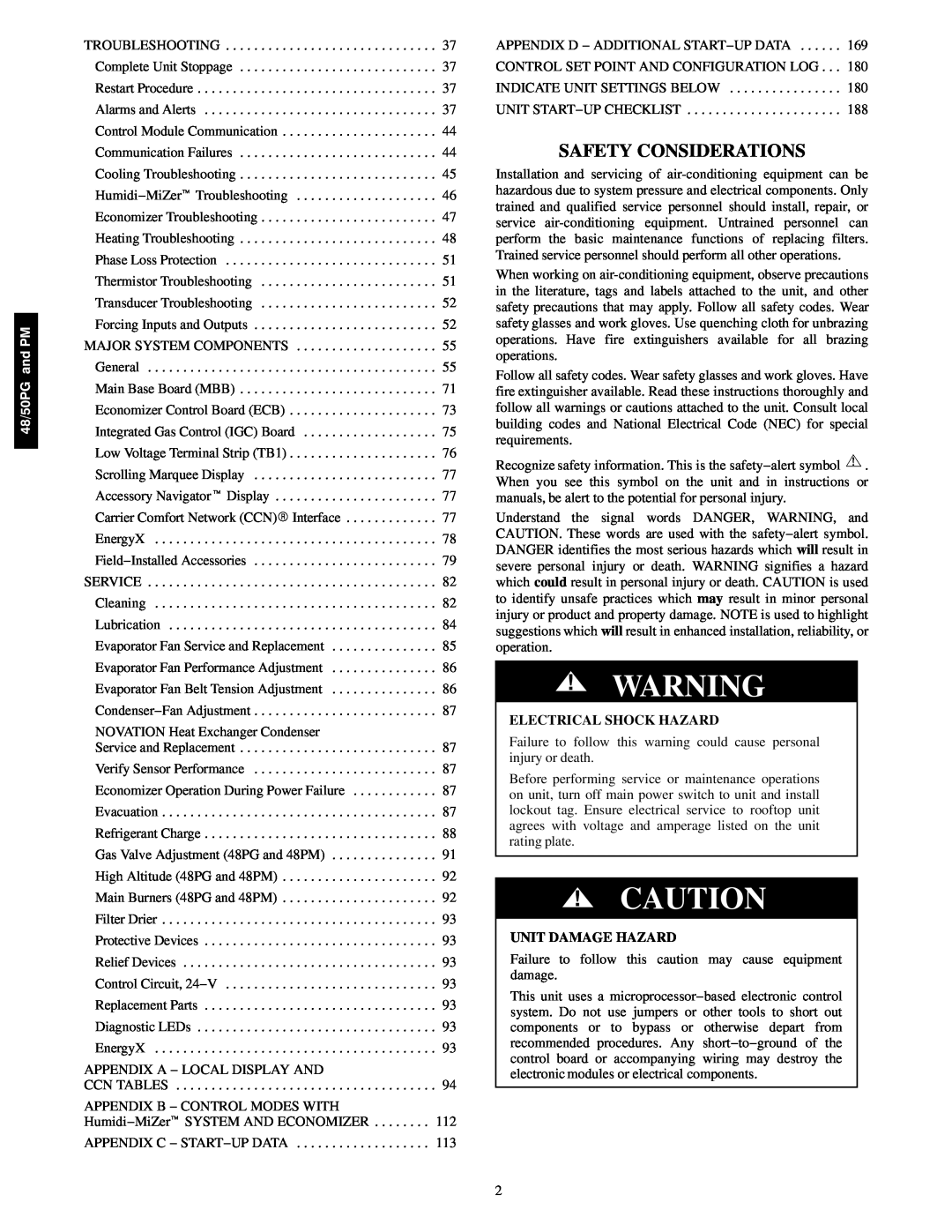

TROUBLESHOOTING | 37 |

Complete Unit Stoppage | 37 |

Restart Procedure | 37 |

Alarms and Alerts | 37 |

Control Module Communication | 44 |

Communication Failures | 44 |

Cooling Troubleshooting | 45 |

Humidi−MiZert Troubleshooting | 46 |

Economizer Troubleshooting | 47 |

Heating Troubleshooting | 48 |

Phase Loss Protection | 51 |

Thermistor Troubleshooting | 51 |

Transducer Troubleshooting | 52 |

Forcing Inputs and Outputs | 52 |

MAJOR SYSTEM COMPONENTS | 55 |

General | 55 |

Main Base Board (MBB) | 71 |

Economizer Control Board (ECB) | 73 |

Integrated Gas Control (IGC) Board | 75 |

Low Voltage Terminal Strip (TB1) | 76 |

Scrolling Marquee Display | 77 |

Accessory Navigatort Display | 77 |

Carrier Comfort Network (CCN)R Interface | 77 |

EnergyX | 78 |

Field−Installed Accessories | 79 |

SERVICE | 82 |

Cleaning | 82 |

Lubrication | 84 |

Evaporator Fan Service and Replacement | 85 |

Evaporator Fan Performance Adjustment | 86 |

Evaporator Fan Belt Tension Adjustment | 86 |

Condenser−Fan Adjustment | 87 |

NOVATION Heat Exchanger Condenser |

|

Service and Replacement | 87 |

Verify Sensor Performance | 87 |

Economizer Operation During Power Failure | 87 |

Evacuation | 87 |

Refrigerant Charge | 88 |

Gas Valve Adjustment (48PG and 48PM) | 91 |

High Altitude (48PG and 48PM) | 92 |

Main Burners (48PG and 48PM) | 92 |

Filter Drier | 93 |

Protective Devices | 93 |

Relief Devices | 93 |

Control Circuit, 24−V | 93 |

Replacement Parts | 93 |

Diagnostic LEDs | 93 |

EnergyX | 93 |

APPENDIX A − LOCAL DISPLAY AND |

|

CCN TABLES | 94 |

APPENDIX B − CONTROL MODES WITH |

|

Humidi−MiZert SYSTEM AND ECONOMIZER | 112 |

APPENDIX C − START−UP DATA | 113 |

APPENDIX D − ADDITIONAL START−UP DATA . . . . . . 169

CONTROL SET POINT AND CONFIGURATION LOG . . . 180

INDICATE UNIT SETTINGS BELOW . . . . . . . . . . . . . . . . 180

UNIT START−UP CHECKLIST . . . . . . . . . . . . . . . . . . . . . . 188

SAFETY CONSIDERATIONS

Installation and servicing of

When working on

Follow all safety codes. Wear safety glasses and work gloves. Have fire extinguisher available. Read these instructions thoroughly and follow all warnings or cautions attached to the unit. Consult local building codes and National Electrical Code (NEC) for special requirements.

Recognize safety information. This is the safety−alert symbol ![]() . When you see this symbol on the unit and in instructions or manuals, be alert to the potential for personal injury.

. When you see this symbol on the unit and in instructions or manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAUTION. These words are used with the safety−alert symbol. DANGER identifies the most serious hazards which will result in severe personal injury or death. WARNING signifies a hazard which could result in personal injury or death. CAUTION is used to identify unsafe practices which may result in minor personal injury or product and property damage. NOTE is used to highlight suggestions which will result in enhanced installation, reliability, or operation.

!WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal injury or death.

Before performing service or maintenance operations on unit, turn off main power switch to unit and install lockout tag. Ensure electrical service to rooftop unit agrees with voltage and amperage listed on the unit rating plate.

!CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may cause equipment damage.

This unit uses a microprocessor−based electronic control system. Do not use jumpers or other tools to short out components or to bypass or otherwise depart from recommended procedures. Any short−to−ground of the control board or accompanying wiring may destroy the electronic modules or electrical components.

2