48/50PG and PM

SCT.A

SCT.A

MOTORMASTER

SENSOR

(3rd return bend down from top)

MOTORMASTER

SENSOR

(bottom stub

of outside header)

48/50PG03,04

C09347

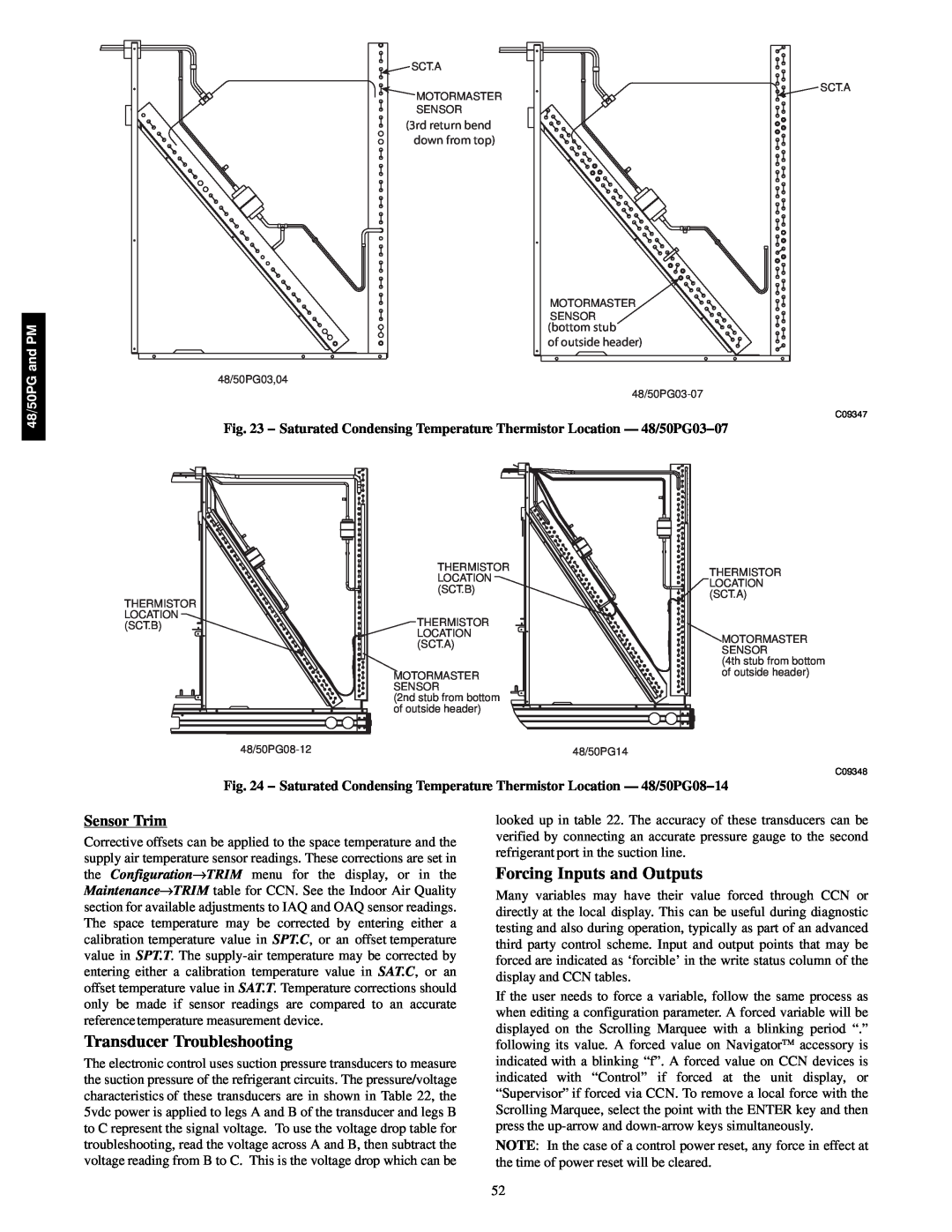

Fig. 23 − Saturated Condensing Temperature Thermistor Location — 48/50PG03−07

| THERMISTOR | THERMISTOR |

| LOCATION | |

| LOCATION | |

| (SCT.B) | |

| (SCT.A) | |

THERMISTOR |

| |

|

| |

LOCATION | THERMISTOR |

|

(SCT.B) |

| |

| LOCATION | MOTORMASTER |

| (SCT.A) | |

| SENSOR | |

|

| |

|

| (4th stub from bottom |

| MOTORMASTER | of outside header) |

| SENSOR |

|

| (2nd stub from bottom |

|

| of outside header) |

|

| 48/50PG14 |

C09348

Fig. 24 − Saturated Condensing Temperature Thermistor Location — 48/50PG08−14

Sensor Trim

Corrective offsets can be applied to the space temperature and the supply air temperature sensor readings. These corrections are set in the Configuration→TRIM menu for the display, or in the Maintenance→TRIM table for CCN. See the Indoor Air Quality section for available adjustments to IAQ and OAQ sensor readings. The space temperature may be corrected by entering either a calibration temperature value in SPT.C, or an offset temperature value in SPT.T. The

Transducer Troubleshooting

The electronic control uses suction pressure transducers to measure the suction pressure of the refrigerant circuits. The pressure/voltage characteristics of these transducers are in shown in Table 22, the 5vdc power is applied to legs A and B of the transducer and legs B to C represent the signal voltage. To use the voltage drop table for troubleshooting, read the voltage across A and B, then subtract the voltage reading from B to C. This is the voltage drop which can be

looked up in table 22. The accuracy of these transducers can be verified by connecting an accurate pressure gauge to the second refrigerant port in the suction line.

Forcing Inputs and Outputs

Many variables may have their value forced through CCN or directly at the local display. This can be useful during diagnostic testing and also during operation, typically as part of an advanced third party control scheme. Input and output points that may be forced are indicated as ‘forcible’ in the write status column of the display and CCN tables.

If the user needs to force a variable, follow the same process as when editing a configuration parameter. A forced variable will be displayed on the Scrolling Marquee with a blinking period “.” following its value. A forced value on Navigator accessory is indicated with a blinking “f”. A forced value on CCN devices is indicated with “Control” if forced at the unit display, or “Supervisor” if forced via CCN. To remove a local force with the Scrolling Marquee, select the point with the ENTER key and then press the

NOTE: In the case of a control power reset, any force in effect at the time of power reset will be cleared.

52