Condenser-Fan Adjustment (Fig. 55)

1.Shut off unit power supply.

2.Remove

3.Adjust fan height as shown in Fig. 55.

4.Tighten setscrews and replace

5.Turn on power to unit.

C09292

Fig. 55 − Condenser−Fan Adjustment

NOVATION Heat Exchanger Condenser Service and Replacement

The condenser coil in this unit is a NOVATION heat exchanger surface. The NOVATION heat exchanger is an all−aluminum construction with fins over a single−depth crosstube. The crosstubes have multiple small passages through which the refrigerant passes from header to header on each end. (See Fig. 56.) The all−aluminum construction provides increased resistance to corrosion over aluminum fins on copper tubes in normal and mild marine applications.

!CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in damage to equipment.

Refer to product data manual for coil usage in coastal or industrial applications.

TUBES

FINS

MANIFOLD

MICROCHANNELS |

C07273

Fig. 56 − NOVATION Heat Exchanger Coils

Repairing Tube Leaks

RCD offers service repair kits for repairing tube leaks in the crosstubes. These kits include approved braze materials and instructions specific to the aluminum NOVATION heat exchanger coil.

!CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in damage to equipment.

Use of other than approved repair procedures may affect the pressure rating or the corrosion resistance of the NOVATION heat exchanger condenser coil.

Replacing the NOVATION Heat Exchanger Coil

The service replacement coil is preformed and is equipped with transition joints with copper stub tubes. When brazing the connection joints to the unit tubing, use a wet cloth around the aluminum tube at the transition joint. Avoid applying torch flame directly onto the aluminum tubing.

Verify Sensor Performance

Verify that thermistor, transducer, and switch inputs are reading correctly. These values can be accessed through the Scrolling Marquee display in the Temperatures, Pressures, and Inputs menus. Some values will depend on configuration choices. Refer to the Control Set Up Checklist completed for the specific unit installation and to the configuration tables in Appendix A.

Economizer Operation During Power Failure

Dampers have a spring return. In event of power failure, dampers will return to fully closed position until power is restored. Do not manually operate damper motor.

Evacuation

Proper evacuation of the system will remove noncondensables and ensure a tight, dry system before charging. Evacuate from both high and low side ports. Never use the system compressor as a vacuum pump. Refrigerant tubes and indoor coil should be evacuated to 500 microns. Always break a vacuum with dry nitrogen. The two possible methods are the deep vacuum method and the triple evacuation method.

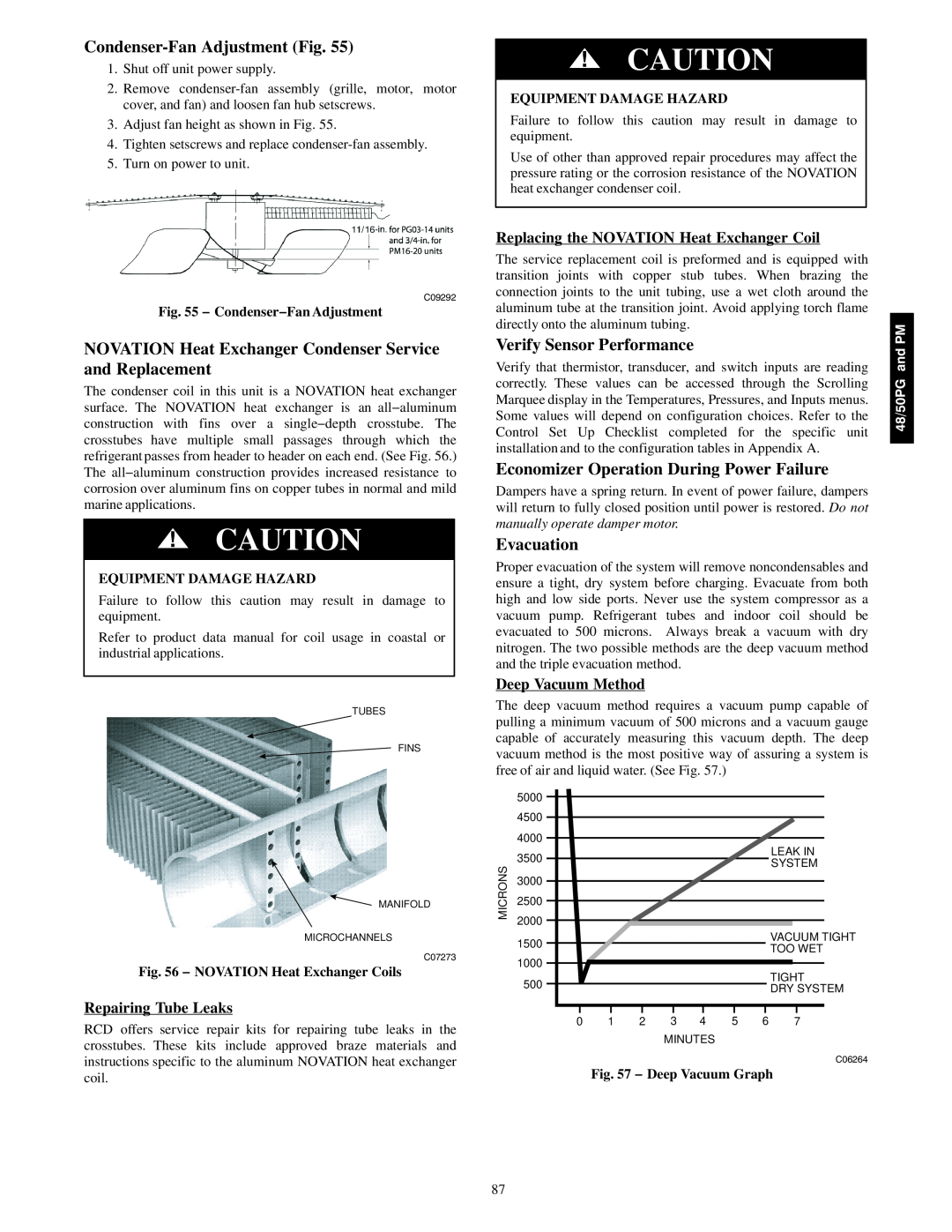

Deep Vacuum Method

The deep vacuum method requires a vacuum pump capable of pulling a minimum vacuum of 500 microns and a vacuum gauge capable of accurately measuring this vacuum depth. The deep vacuum method is the most positive way of assuring a system is free of air and liquid water. (See Fig. 57.)

| 5000 |

|

|

|

|

|

|

|

| 4500 |

|

|

|

|

|

|

|

| 4000 |

|

|

|

|

|

|

|

| 3500 |

|

|

|

|

|

| LEAK IN |

MICRONS |

|

|

|

|

|

| SYSTEM | |

|

|

|

|

|

|

| ||

3000 |

|

|

|

|

|

|

| |

2500 |

|

|

|

|

|

|

| |

2000 |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

| 1500 |

|

|

|

|

|

| VACUUM TIGHT |

|

|

|

|

|

|

| TOO WET | |

|

|

|

|

|

|

|

| |

| 1000 |

|

|

|

|

|

|

|

| 500 |

|

|

|

|

|

| TIGHT |

|

|

|

|

|

|

| DRY SYSTEM | |

|

|

|

|

|

|

|

| |

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|

|

|

| MINUTES |

|

|

| |

|

|

|

|

|

|

|

| C06264 |

Fig. 57 − Deep Vacuum Graph

48/50PG and PM

87