Be sure unit is in normal cooling mode by checking that the RH2 solenoid coil(s) and the CRC relay are deenergized (control outputs off). Adjust charge per the charging charts as described in the To Use The Cooling Charging Charts, Standard Unit section. Switch system to run in the dehumidification mode for 5 minutes. Dehumidification mode is when the RH2 solenoid coil(s) and the CRC relay are energized. Switch back to cooling mode to recheck pressures and temperatures on the charging chart and adjust charge if necessary. If charge adjustment is necessary, then repeat the steps in this paragraph until no charge adjustment is necessary. When no more charge adjustment is necessary after switching from Dehumidification mode back to Cooling mode, then charge adjustment procedure is complete. Remove jumper from the outdoor motor speed controller.

PuronR Refrigerant

Puron refrigerant operates at 50 to 70 percent higher pressures than

Recovery cylinder service pressure rating must be 400 psig. Puron systems should be charged with liquid refrigerant. Use a

Table 28 – Altitude Compensation*

48PG03−07

ELEVATION | NATURAL GAS | PROPANE |

(ft) | ORIFICE† | ORIFICE† |

| 45 | 52 |

| 47 | 52 |

| 47 | 53 |

| 47 | 53 |

| 48 | 53 |

| 48 | 53 |

| 48 | 53 |

| 49 | 54 |

| 49 | 54 |

| 50 | 54 |

| 51 | 54 |

| 51 | 55 |

| 52 | 55 |

| 52 | 56 |

48PG08−14

ELEVATION | NATURAL GAS | PROPANE |

(ft) | ORIFICE† | ORIFICE† |

| 43 | 50 |

| 44 | 51 |

| 44 | 51 |

| 44 | 51 |

| 45 | 51 |

| 45 | 52 |

| 47 | 52 |

| 47 | 52 |

| 47 | 53 |

| 48 | 53 |

| 49 | 53 |

| 50 | 54 |

| 50 | 54 |

| 51 | 55 |

48PG08−14

ELEVATION | NATURAL GAS | PROPANE |

(ft) | ORIFICE† | ORIFICE† |

| 30 | 38 |

| 30 | 40 |

| 31 | 40 |

| 31 | 41 |

| 31 | 41 |

| 31 | 42 |

| 32 | 42 |

| 32 | 43 |

| 32 | 43 |

| 35 | 44 |

| 36 | 44 |

| 37 | 45 |

| 38 | 46 |

| 39 | 47 |

*As the height above sea level increases, there is less oxygen per cubic foot of air. Therefore, heat input rate should be reduced at higher altitudes. Includes a 4% input reduction per each 1000 ft.

†Orifices available through your Carrier dealer.

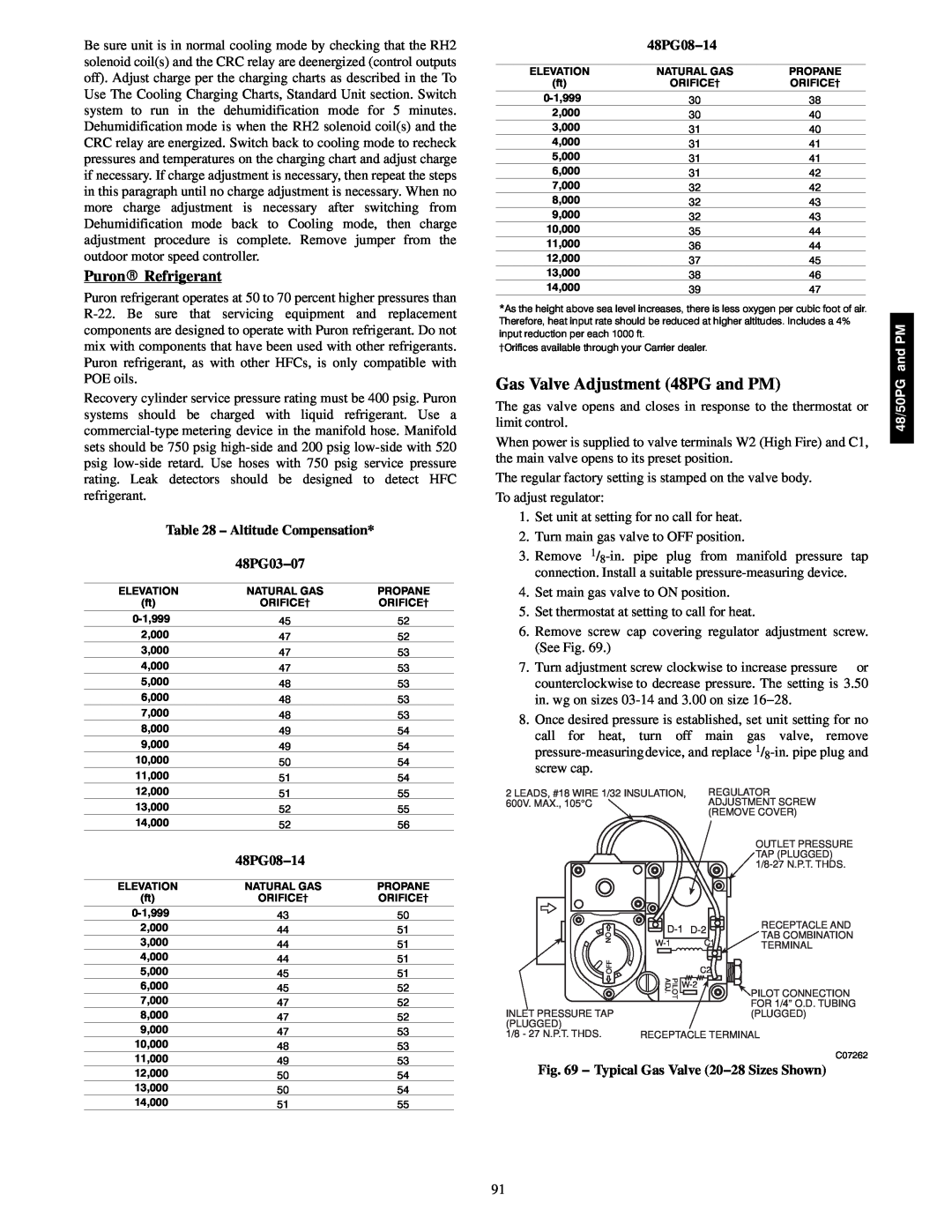

Gas Valve Adjustment (48PG and PM)

The gas valve opens and closes in response to the thermostat or limit control.

When power is supplied to valve terminals W2 (High Fire) and C1, the main valve opens to its preset position.

The regular factory setting is stamped on the valve body.

To adjust regulator:

1.Set unit at setting for no call for heat.

2.Turn main gas valve to OFF position.

3.Remove

4.Set main gas valve to ON position.

5.Set thermostat at setting to call for heat.

6.Remove screw cap covering regulator adjustment screw. (See Fig. 69.)

7. Turn adjustment screw clockwise to increase pressure or counterclockwise to decrease pressure. The setting is 3.50 in. wg on sizes

8.Once desired pressure is established, set unit setting for no call for heat, turn off main gas valve, remove

2 LEADS, #18 WIRE 1/32 INSULATION, | REGULATOR |

600V. MAX., 105°C | ADJUSTMENT SCREW |

| (REMOVE COVER) |

OUTLET PRESSURE TAP (PLUGGED)

| RECEPTACLE AND | ||||

ON | TAB COMBINATION | ||||

| C1 | ||||

| TERMINAL | ||||

|

| ||||

OFF |

|

| C2 |

| |

| PILOT ADJ. | PILOT CONNECTION | |||

|

|

| |||

INLET PRESSURE TAP |

|

|

| FOR 1/4” O.D. TUBING | |

|

|

| (PLUGGED) | ||

(PLUGGED) |

|

|

|

| |

1/8 - 27 N.P.T. THDS. | RECEPTACLE TERMINAL | ||||

C07262

Fig. 69 − Typical Gas Valve (20−28 Sizes Shown)

48/50PG and PM

91