48/50PG and PM

Table 27 – Belt Tension Adjustment

|

|

|

|

| BELT TENSION (lb) |

|

|

| |

48PM | VOLTAGE |

|

|

| Unit Model Number Position 10 |

|

|

| |

|

| A,J | B,K | C,L | D,M | E,N | F,P | G,Q | H,R |

| 230 | 4.8 | 5.1 | 5.6 | 4.5 | NA | 4.7 | 5.0 | 5.5 |

16 | 460 | 4.8 | 5.1 | 5.6 | 4.5 | NA | 4.7 | 5.0 | 5.5 |

| 575 | 5.3 | 5.1 | 5.6 | 4.5 | NA | 5.2 | 5.0 | 5.5 |

| 230 | 4.8 | 5.1 | 5.6 | 4.5 | NA | 4.7 | 5.0 | 5.5 |

20 | 460 | 4.8 | 5.1 | 5.6 | 4.5 | NA | 4.7 | 5.0 | 5.5 |

| 575 | 5.3 | 5.1 | 5.6 | 4.5 | NA | 5.2 | 5.0 | 5.5 |

| 230 | 4.8 | 5.1 | 5.6 | 4.5 | NA | 4.7 | 5.0 | 5.5 |

24 | 460 | 4.8 | 5.1 | 5.6 | 4.5 | NA | 4.7 | 5.0 | 5.5 |

| 575 | 5.3 | 5.1 | 5.6 | 4.5 | NA | 5.2 | 5.0 | 5.5 |

| 230 | 4.5 | 5.4 | 5.9 | 4.5 | 4.5 | 5.4 | 5.9 | 4.5 |

28 | 460 | 4.5 | 5.4 | 5.9 | 4.5 | 4.5 | 5.4 | 5.9 | 4.5 |

| 575 | 4.5 | 5.4 | 5.9 | 4.5 | 4.5 | 5.4 | 5.9 | 4.5 |

|

|

|

|

| BELT TENSION (lb) |

|

|

| |

50PM | VOLTAGE |

|

|

| Unit Model Number Position 10 |

|

|

| |

|

| A,J | B,K | C,L | D,M | E,N | F,P | G,Q | H,R |

| 230 | 4.8 | 5.1 | 5.6 | 4.5 | 4.8 | 5.1 | 5.6 | 4.5 |

16 | 460 | 4.8 | 5.1 | 5.6 | 4.5 | 4.8 | 5.1 | 5.6 | 4.5 |

| 575 | 5.3 | 5.1 | 5.6 | 4.5 | 5.3 | 5.1 | 5.6 | 4.5 |

| 230 | 4.8 | 5.1 | 5.6 | 4.5 | 4.8 | 5.1 | 5.6 | 4.5 |

20 | 460 | 4.8 | 5.1 | 5.6 | 4.5 | 4.8 | 5.1 | 5.6 | 4.5 |

| 575 | 5.3 | 5.1 | 5.6 | 4.5 | 5.3 | 5.1 | 5.6 | 4.5 |

| 230 | 4.8 | 5.1 | 5.6 | 4.5 | 4.8 | 5.1 | 5.6 | 4.5 |

24 | 460 | 4.8 | 5.1 | 5.6 | 4.5 | 4.8 | 5.1 | 5.6 | 4.5 |

| 575 | 5.3 | 5.1 | 5.6 | 4.5 | 5.3 | 5.1 | 5.6 | 4.5 |

| 230 | 4.5 | 5.4 | 5.9 | 4.5 | 4.5 | 5.4 | 5.9 | 4.5 |

28 | 460 | 4.5 | 5.4 | 5.9 | 4.5 | 4.5 | 5.4 | 5.9 | 4.5 |

| 575 | 4.5 | 5.4 | 5.9 | 4.5 | 4.5 | 5.4 | 5.9 | 4.5 |

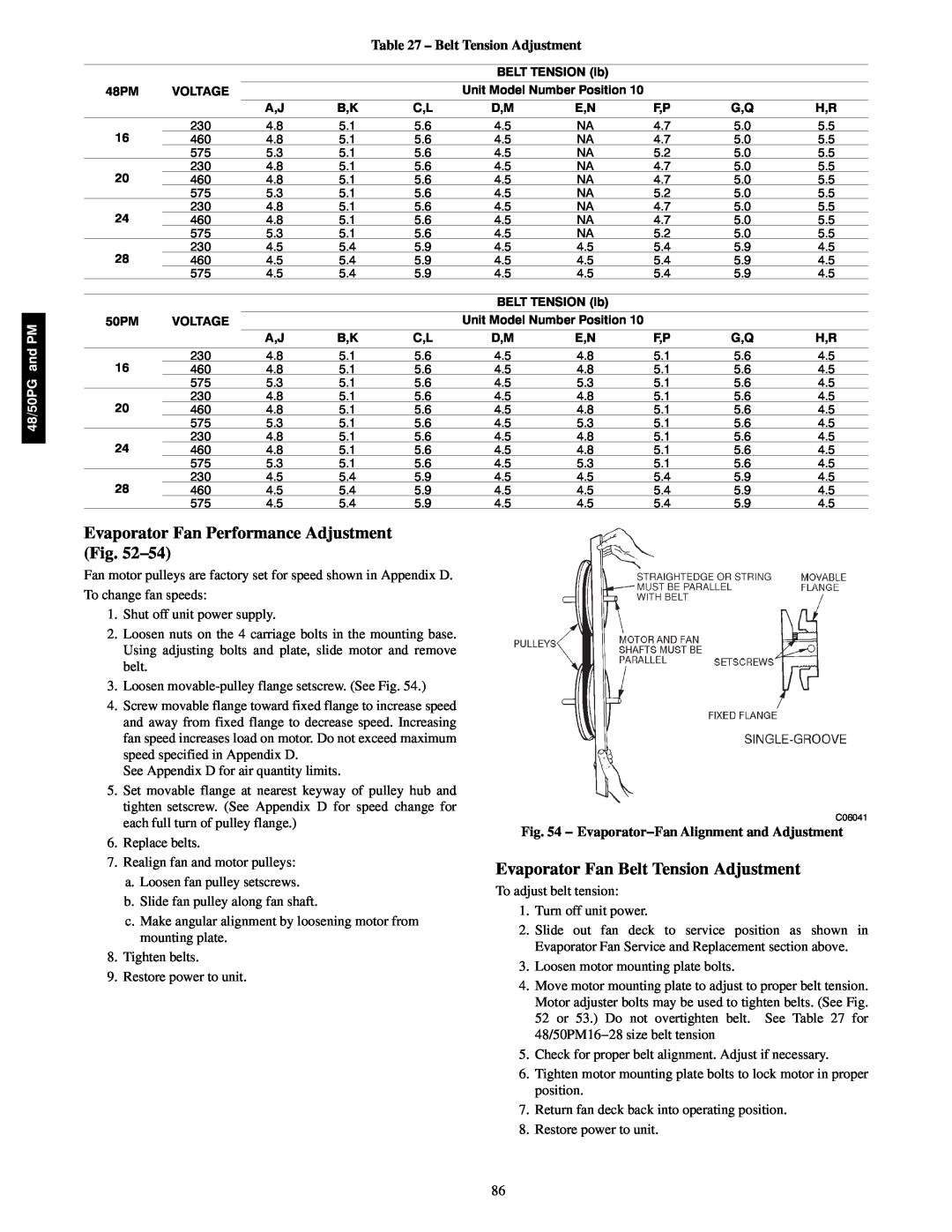

Evaporator Fan Performance Adjustment (Fig. 52−54)

Fan motor pulleys are factory set for speed shown in Appendix D.

To change fan speeds:

1.Shut off unit power supply.

2.Loosen nuts on the 4 carriage bolts in the mounting base. Using adjusting bolts and plate, slide motor and remove belt.

3.Loosen

4.Screw movable flange toward fixed flange to increase speed and away from fixed flange to decrease speed. Increasing fan speed increases load on motor. Do not exceed maximum speed specified in Appendix D.

See Appendix D for air quantity limits.

5.Set movable flange at nearest keyway of pulley hub and tighten setscrew. (See Appendix D for speed change for each full turn of pulley flange.)

6.Replace belts.

7.Realign fan and motor pulleys:

a.Loosen fan pulley setscrews.

b.Slide fan pulley along fan shaft.

c.Make angular alignment by loosening motor from mounting plate.

8.Tighten belts.

9.Restore power to unit.

C06041

Fig. 54 − Evaporator−Fan Alignment and Adjustment

Evaporator Fan Belt Tension Adjustment

To adjust belt tension:

1.Turn off unit power.

2.Slide out fan deck to service position as shown in Evaporator Fan Service and Replacement section above.

3.Loosen motor mounting plate bolts.

4.Move motor mounting plate to adjust to proper belt tension. Motor adjuster bolts may be used to tighten belts. (See Fig. 52 or 53.) Do not overtighten belt. See Table 27 for 48/50PM16−28 size belt tension

5.Check for proper belt alignment. Adjust if necessary.

6.Tighten motor mounting plate bolts to lock motor in proper position.

7.Return fan deck back into operating position.

8.Restore power to unit.

86