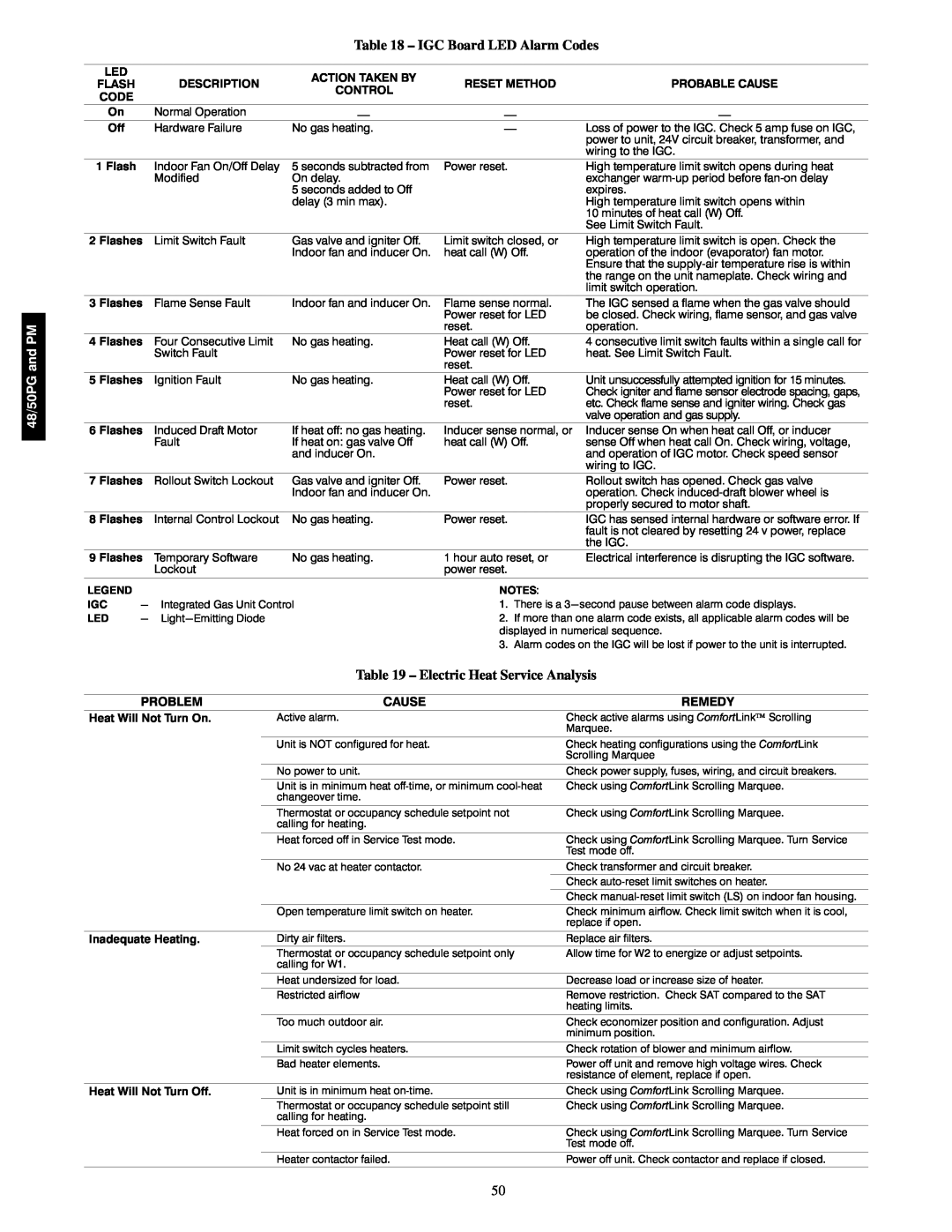

Table 18 – IGC Board LED Alarm Codes

LED

FLASH DESCRIPTION CODE

On Normal Operation

Off Hardware Failure

1 Flash Indoor Fan On/Off Delay Modified

ACTION TAKEN BY

CONTROL

—

No gas heating.

5 seconds subtracted from On delay.

5 seconds added to Off delay (3 min max).

RESET METHOD | PROBABLE CAUSE |

——

—Loss of power to the IGC. Check 5 amp fuse on IGC, power to unit, 24V circuit breaker, transformer, and wiring to the IGC.

Power reset. | High temperature limit switch opens during heat |

| exchanger warm‐up period before fan‐on delay |

| expires. |

| High temperature limit switch opens within |

| 10 minutes of heat call (W) Off. |

| See Limit Switch Fault. |

48/50PG and PM

2 Flashes | Limit Switch Fault | Gas valve and igniter Off. | |

|

|

| Indoor fan and inducer On. |

3 Flashes | Flame Sense Fault | Indoor fan and inducer On. | |

4 Flashes | Four Consecutive Limit | No gas heating. | |

|

| Switch Fault |

|

5 Flashes | Ignition Fault | No gas heating. | |

6 Flashes | Induced Draft Motor | If heat off: no gas heating. | |

|

| Fault | If heat on: gas valve Off |

|

|

| and inducer On. |

7 Flashes | Rollout Switch Lockout | Gas valve and igniter Off. | |

|

|

| Indoor fan and inducer On. |

8 Flashes | Internal Control Lockout | No gas heating. | |

9 Flashes | Temporary Software | No gas heating. | |

|

| Lockout |

|

LEGEND |

|

|

|

IGC | - | Integrated Gas Unit Control | |

LED | - |

| |

Limit switch closed, or | High temperature limit switch is open. Check the |

heat call (W) Off. | operation of the indoor (evaporator) fan motor. |

| Ensure that the supply‐air temperature rise is within |

| the range on the unit nameplate. Check wiring and |

| limit switch operation. |

Flame sense normal. | The IGC sensed a flame when the gas valve should |

Power reset for LED | be closed. Check wiring, flame sensor, and gas valve |

reset. | operation. |

Heat call (W) Off. | 4 consecutive limit switch faults within a single call for |

Power reset for LED | heat. See Limit Switch Fault. |

reset. |

|

Heat call (W) Off. | Unit unsuccessfully attempted ignition for 15 minutes. |

Power reset for LED | Check igniter and flame sensor electrode spacing, gaps, |

reset. | etc. Check flame sense and igniter wiring. Check gas |

| valve operation and gas supply. |

Inducer sense normal, or | Inducer sense On when heat call Off, or inducer |

heat call (W) Off. | sense Off when heat call On. Check wiring, voltage, |

| and operation of IGC motor. Check speed sensor |

| wiring to IGC. |

Power reset. | Rollout switch has opened. Check gas valve |

| operation. Check induced‐draft blower wheel is |

| properly secured to motor shaft. |

Power reset. | IGC has sensed internal hardware or software error. If |

| fault is not cleared by resetting 24 v power, replace |

| the IGC. |

1 hour auto reset, or | Electrical interference is disrupting the IGC software. |

power reset. |

|

NOTES:

1.There is a

2.If more than one alarm code exists, all applicable alarm codes will be displayed in numerical sequence.

3.Alarm codes on the IGC will be lost if power to the unit is interrupted.

Table 19 – Electric Heat Service Analysis

PROBLEM

Heat Will Not Turn On.

Inadequate Heating.

Heat Will Not Turn Off.

CAUSE

Active alarm.

Unit is NOT configured for heat.

No power to unit.

Unit is in minimum heat off‐time, or minimum cool‐heat changeover time.

Thermostat or occupancy schedule setpoint not calling for heating.

Heat forced off in Service Test mode.

No 24 vac at heater contactor.

Open temperature limit switch on heater.

Dirty air filters.

Thermostat or occupancy schedule setpoint only calling for W1.

Heat undersized for load.

Restricted airflow

Too much outdoor air.

Limit switch cycles heaters.

Bad heater elements.

Unit is in minimum heat on‐time.

Thermostat or occupancy schedule setpoint still calling for heating.

Heat forced on in Service Test mode.

Heater contactor failed.

REMEDY

Check active alarms using ComfortLink Scrolling Marquee.

Check heating configurations using the ComfortLink Scrolling Marquee

Check power supply, fuses, wiring, and circuit breakers. Check using ComfortLink Scrolling Marquee.

Check using ComfortLink Scrolling Marquee.

Check using ComfortLink Scrolling Marquee. Turn Service Test mode off.

Check transformer and circuit breaker. Check auto‐reset limit switches on heater.

Check manual‐reset limit switch (LS) on indoor fan housing.

Check minimum airflow. Check limit switch when it is cool, replace if open.

Replace air filters.

Allow time for W2 to energize or adjust setpoints.

Decrease load or increase size of heater.

Remove restriction. Check SAT compared to the SAT heating limits.

Check economizer position and configuration. Adjust minimum position.

Check rotation of blower and minimum airflow.

Power off unit and remove high voltage wires. Check resistance of element, replace if open.

Check using ComfortLink Scrolling Marquee.

Check using ComfortLink Scrolling Marquee.

Check using ComfortLink Scrolling Marquee. Turn Service Test mode off.

Power off unit. Check contactor and replace if closed.

50