48/50PG and PM

Condenser Fans and Motors

Condenser fans and motors are factory set. Refer to

Return−Air Filters

Check that correct filters are installed in filter tracks (see Physical Data table in Installation Instructions). Do not operate unit without

NOTE: For units with

Outdoor−Air Inlet Screens

Air Baffles

Units with

Accessory Installation

Check to make sure that all accessories including space thermostats and sensors have been installed and wired as required by the instructions and unit wiring diagrams.

Orifice Change (48PG and 48PM)

This unit is factory assembled for heating operation using natural gas at an elevation from sea level to 2000 ft.

Use accessory high altitude kit when installing this unit at an elevation of 2000 to 7000 ft. For elevations above 7000 ft, refer to High Altitude section to identify the correct orifice size for the elevation. Purchase these orifices from your local Carrier dealer. Follow instructions in accessory Installation Instructions to install the correct orifices.

Use accessory LP (liquid propane) gas conversion kit when converting this unit for use with LP fuel usage for elevations up to 7000 ft. For elevations above 7000 ft, refer to High Altitude section to identify the correct orifice size for the elevation. Purchase these orifices from your local Carrier dealer. Follow instructions in accessory Installation Instructions to install the correct orifices.

Gas Heat (48PG and 48PM)

Inspect the gas heat section of the unit. Verify the number of burners match the number of heat exchanger openings and the burner assembly is properly aligned. If the orifices were changed out for elevation or Liquid Propane purposes, verify proper installation. Visually inspect other components in heat section.

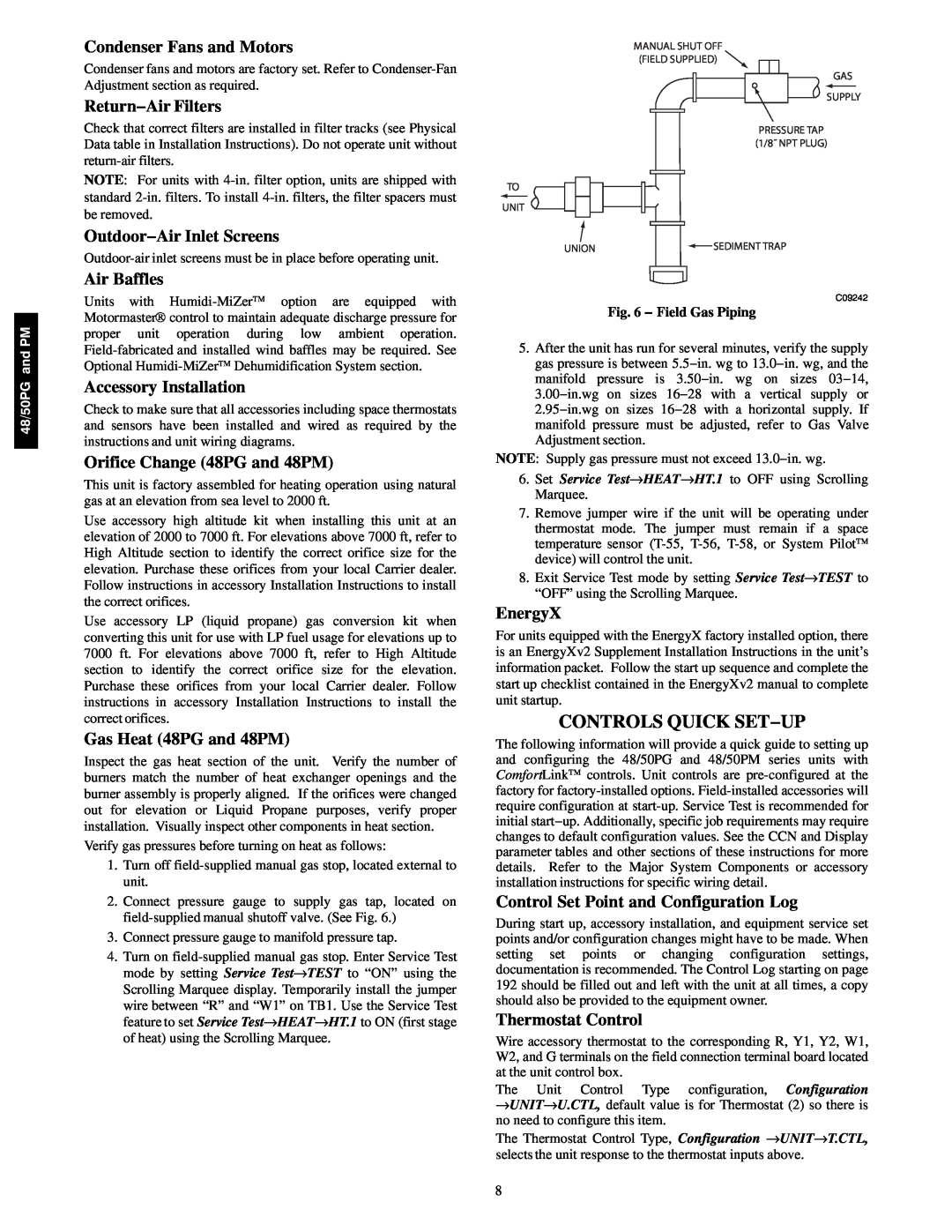

Verify gas pressures before turning on heat as follows:

1.Turn off

2.Connect pressure gauge to supply gas tap, located on

3.Connect pressure gauge to manifold pressure tap.

4.Turn on

wire between “R” and “W1” on TB1. Use the Service Test feature to set Service Test→HEAT→HT.1 to ON (first stage of heat) using the Scrolling Marquee.

MANUAL SHUT OFF

(FIELD SUPPLIED)

GAS

SUPPLY

PRESSURE TAP (1/8˝ NPT PLUG)

TO

UNIT

UNION |

| SEDIMENT TRAP |

|

C09242

Fig. 6 − Field Gas Piping

5.After the unit has run for several minutes, verify the supply gas pressure is between 5.5−in. wg to 13.0−in. wg, and the manifold pressure is 3.50−in. wg on sizes 03−14, 3.00−in.wg on sizes 16−28 with a vertical supply or 2.95−in.wg on sizes 16−28 with a horizontal supply. If manifold pressure must be adjusted, refer to Gas Valve Adjustment section.

NOTE: Supply gas pressure must not exceed 13.0−in. wg.

6.Set Service Test→HEAT→HT.1 to OFF using Scrolling Marquee.

7.Remove jumper wire if the unit will be operating under

thermostat mode. The jumper must remain if a space temperature sensor

8.Exit Service Test mode by setting Service Test→TEST to “OFF” using the Scrolling Marquee.

EnergyX

For units equipped with the EnergyX factory installed option, there is an EnergyXv2 Supplement Installation Instructions in the unit’s information packet. Follow the start up sequence and complete the start up checklist contained in the EnergyXv2 manual to complete unit startup.

CONTROLS QUICK SET−UP

The following information will provide a quick guide to setting up and configuring the 48/50PG and 48/50PM series units with ComfortLink controls. Unit controls are

Control Set Point and Configuration Log

During start up, accessory installation, and equipment service set points and/or configuration changes might have to be made. When setting set points or changing configuration settings, documentation is recommended. The Control Log starting on page 192 should be filled out and left with the unit at all times, a copy should also be provided to the equipment owner.

Thermostat Control

Wire accessory thermostat to the corresponding R, Y1, Y2, W1, W2, and G terminals on the field connection terminal board located at the unit control box.

The Unit Control Type configuration, Configuration →UNIT→U.CTL, default value is for Thermostat (2) so there is no need to configure this item.

The Thermostat Control Type, Configuration →UNIT→T.CTL, selects the unit response to the thermostat inputs above.

8