Section TOC

Master TOC

|

|

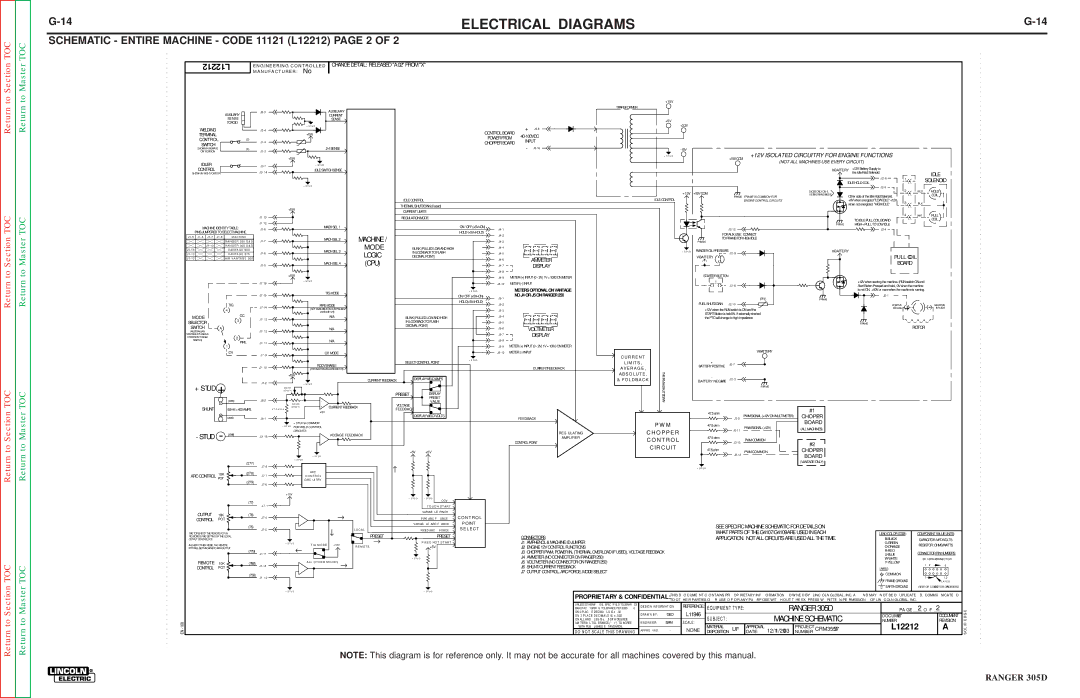

| ELECTRICAL DIAGRAMS | |||

SCHEMATIC - ENTIRE MACHINE - CODE 11121 (L12212) PAGE 2 OF 2 |

|

|

|

|

| |

|

| E N G IN E ER IN G CO N TRO LLE D |

| CHANGE DETAIL: RELEASED"A.02" FROM "X" |

| |

|

|

|

| |||

| L12212 | M AN U FA C TU R ER : | No |

|

|

|

|

|

|

|

|

| |

to

to

AUXILIARY

AUXILLARY |

CURRENT |

TRANSFORMER

+15V

Return

Return

WELDING

SENSE TOROID

SENSE |

+ S T U D |

+5V +3.3V

Return to Section TOC

to Section TOC

Return to Master TOC

to Master TOC

TERMINAL

CONTROL(2)

SWITCH ![]() (4) SHOWNIN"ALWAYS

(4) SHOWNIN"ALWAYS

ON" POSITION

IDLER

CONTROL

SHOWNIN"HIGH" POSITION

| MACHINE IDENTITY TABLE: | |

| PINS JUMPERED TO SELECTMACHINE | |

M A C H IN E | ||

| RA NG E R 250 G & D | |

RA NG E R 305 G & D | ||

| V A NTA G E 500 | |

| V A NTA G E 575 | |

| A IR V A NTA G E 500 | |

MODE | 4 TIG | CC | |

3 | |||

SELECTOR |

| ||

SWITCH | A |

| |

(AUSTRAILIAN |

|

| |

VANTAGE575 USESA | 2 PIPE | ||

3POSITIONTOGGLE | |||

SWITCH) | |||

| 1 CV |

| |

+ STUD + |

| |

SHUNT | - | (206S) |

| ||

+ | 50mV =400AMPS | |

| (204S) | |

- STUD - | (208B) | |

(277)

J3- 14

J7- 13

J7- 12

J7- 11

J7

J7- 10

J3- 15

|

| +15V |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

+15V | + S T U D |

|

|

|

|

| ||

|

|

|

|

|

|

| ||

|

| IDLE SWITCH SENSE |

|

|

|

| ||

|

| + S T UD |

|

|

|

|

|

|

|

|

|

|

|

| IDLE CONTROL |

| |

+15V |

|

|

|

| THERMALSHUTDOWN (if used) | |||

|

|

|

| CURRENTLIMITS | ||||

|

|

|

|

|

| REGULATION MODE | ||

|

|

| MACH SEL1 | MACHINE / |

|

|

| |

|

|

| MACH SEL2 |

|

|

| ||

|

|

| MACH SEL3 | MODE |

| BLINK (PULLED LOW AND HIGH | ||

|

|

| LOGIC |

| INLOOKBACK TO FLASH | |||

|

|

|

|

|

| DECIMALPOINT) | ||

|

|

| MACH SEL4 | (CPU) |

|

|

| |

+15V | + S T UD |

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

| TIG MODE |

|

|

|

|

|

| PIPE MODE |

|

|

|

| ||

|

| (NOTAVAILABLEONAUSTRALIAN |

|

|

|

| ||

|

| VANTAGE575) |

| BLINK (PULLED LOW AND HIGH | ||||

|

|

|

| N/A |

| |||

|

|

|

|

|

| IN LOOKBACK TO FLASH | ||

|

|

|

| N/A |

| DECIMALPOINT) | ||

|

|

|

|

|

|

|

| |

|

|

|

| N/A |

|

|

|

|

|

|

| CV MODE |

|

|

|

| |

|

| ROCV ENABLE |

| SELECTCONTROLPOINT | ||||

|

|

|

|

|

| |||

+15V | (FORAUSTRALIANVANTAGE575) |

|

|

|

| |||

|

|

| CURRENT FEEDBACK | DISPLAY WELD AMPS | ||||

|

| + S T UD |

|

| ||||

G 41 0 7 |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

(O N L Y ) |

|

|

|

| PRESET |

| DISPLAY | |

|

|

|

|

|

|

| ||

|

| - |

|

|

|

|

| PRESET |

| G 4 10 9 |

| CURRENT FEEDBACK |

| VOLTAGE |

| VALUE | |

47 .5 ohm s | (O N L Y ) | + |

|

|

|

| ||

| x80 |

|

| FEEDBACK |

| |||

|

|

|

|

| DISPLAY WELD VOLTS | |||

|

|

|

|

|

|

| ||

+ S T U D | + STUD is COMMON |

|

|

|

|

|

| |

FOR WELD CONTROL |

|

|

|

|

|

| ||

| CIRCUITS |

| VOLTAGE FEEDBACK |

|

|

| ||

|

|

|

|

|

|

| ||

|

| + S T U D |

|

|

|

| +5V | +5V |

| + S T U D |

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

CONTROLBOARD | |||

POWER FROM | |||

CHOPPER BOARD |

| INPUT | |

| - |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| +12V ISOLATED CIRCUITRY FOR ENGINE FUNCTIONS |

| ||||

+ S T U D | +15V COM |

| ||||

| (NOT ALL MACHINES USE EVERY CIRCUIT) |

|

| |||

|

|

|

| |||

|

|

|

|

| ||

|

|

|

| the IdleHoldSolenoid | J2 | 1 |

|

|

|

| IDLE HOLD COIL | ||

|

|

|

|

| ||

+15V +15V COM |

|

| DIODEONLY |

| 2 | |

|

| Other sideof the IdleHoldSolenoid. | ||||

FRAME FRAME IS COMMON FOR | VERSIONAND BOVEA |

| ||||

IDLE CONTROL |

| ENGINE CONTROL CIRCUITS |

| +0V when energized"LOW IDLE" +12V | 3 | |

|

|

|

| whennot energized. "HIGH IDLE" | ||

|

|

|

| TO IDLE PULLCOILBOARD | 4 | |

|

|

|

|

| ||

IDLE

SOLENOID

RED HOLD

COIL

BLK

WHT PULL

COIL

ON / OFF(+5V=ON) | ||

HOLD (+5V=HOLD) | ||

|

| FRAME | HIGH =PULLTO LOW IDLE | |

|

| ||

| FOR AUX USE: CONNECT |

|

|

FRAME | TO FRAME FOR HIGH IDLE |

|

|

|

|

|

AMMETER DISPLAY

+S T U D RANGER OILPRESSURE J2

PULL COIL

BOARD

+ S TU D |

METER (+) INPUT (0- 2V) 1V =1000ON METER METER

METERS OPTIONAL ON VANTAGE

STARTER BUTTON

J2 |

+12V whenstarting themachine. (RUN switchON and Start ButtonPressedandheld., 0V when themachine isnot ON. +40V or morewhen themachineis running.

ON/ OFF(+5V=ON) | |

HOLD(+5V=HOLD) | |

| |

|

NO J4 OR J5 ON RANGER 250

FUELSHUTDOWN |

| PTC |

| ||

+12V when the RUN switchisON and the |

| |

STARTButtonis held IN. If externallyshorted the PTC will change tohighimpedance

FRAME

-NEGATIVE BRUSH

+ S TU D |

VOLTMETER

DISPLAY

METER (+) INPUT (0 - 2V) 1V =100.0 ON METER METER

C U R R E N T |

L IM IT S , |

FRAME | ROTOR |

|

+

CURRENTFEEDBACK

FEEDBACK

REG ULATING

CONTROLPOINTAMPLIFIER

A V E R A G E , |

|

A B S O L U T E , | THERMALSHUTDOWN |

& F O L D B A C K | |

|

P W M

C H O P P E R

C O N T R O L

C IR C U IT

BATTERY POSITIVE

-J2

BATTERY NEGATIVE

FRAME

| 47.5ohm |

| PWM SIGNAL(+12V ON MULTIMETER) |

| #1 |

|

|

| ||||||||||

|

|

|

|

|

| |||||||||||||

|

| CHOPPER |

| |||||||||||||||

47.5 ohm |

| PWM SIGNAL(+12V) |

|

|

|

|

|

|

|

|

| BOARD |

| |||||

|

|

|

|

|

|

|

|

|

| |||||||||

47.5 ohm |

|

|

|

|

|

|

| (ALLMACHINES) |

| |||||||||

| PWM COMMON |

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

| #2 |

|

|

| ||||

47.5ohm |

| PWMCOMMON |

|

|

|

|

| CHOPPER |

| |||||||||

|

|

| ||||||||||||||||

|

|

|

|

|

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| BOARD |

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

| (VANTAGE ONLY) | |||||

+ S T U D

Return

TOC

Return

TOC

ARC CONTROL 10K

(278)

(278)

POT(279)

|

| (77) | |

OUTPUT | 10K | (76) | |

CONTROL | POT | (75) | |

THETOPENDOFTHEREMOTEPOT IN | |||

| |||

TIG MODEISTHESETTING OFTHELOCAL |

| ||

OUTPUT CONTROLPOT. |

|

| |

INEVERYOTHERMODE,THEREMOTE |

| ||

POTWILLSET MACHINETO MAXOUTPUT. | (77B) | ||

|

| ||

REMOTE | 10K | (76B) | |

CONTROL | POT | (75B) | |

|

| ||

J7

J1- 10

ARC

C O N TR O L

CIRC UI TRY

+10V

LO C AL

PRESET

+ S T U D | T IG M O D E +10V | R E M O T E |

|

A LL O TH E R M O D E S

+ S T U D | + S T U D | OCV |

| T O U C H ST A R T | |

VARIAB LE PINCH | ||

PIPE ARC F | ORCE | |

VARIAB | LE ARC F ORCE | |

FIXED ARC | FORCE | |

|

| PRESET |

FIX E D HO T S T A R T +5V

+ S T U D

C O N T R O L |

|

|

|

|

|

P OINT |

| SEE SPECIFICMACHINE SCHEMATICFORDETAILSON |

|

|

|

S E L E C T |

|

|

|

| |

CONNECTORS | WHATPARTS OF THE G4107/G4109ARE USEDINEACH | LEAD COLOR CODE: | COMPONENTVALUE UNITS: | ||

APPLICATION. NOTALL CIRCUITS ARE USEDALL THE TIME. | CAPACITOR: MFD/VOLTS | ||||

J1 | AMPHENOL& MACHINE ID JUMPER |

| RESISTOR: OHMS/WATTS | ||

J2 | ENGINE 12V CONTROL FUNCTIONS |

| |||

J3 | CHOPPER PWM, POWER IN, (THERMALOVERLOAD IFUSED), VOLTAGE FEEDBACK |

| CONNECTOR PIN NUMBERS: | ||

| |||||

J4 | AMMETER (NO CONNECTOR ON RANGER 250) |

| EX. 12PIN ONNECTOR | ||

J5 | VOLTMETER (NO CONNECTOR ON RANGER 250) |

| 1 2 | 6 | |

J6 | SHUNT/CURRENTFEEDBACK |

| LABELS: | ||

J7 | OUTPUTCONTROL, ARC FORCE, MODE SELECT |

| COMMON | 7 | 1 2 |

|

|

| FRAME GROUND | ||

|

|

|

| L A T C H | |

|

|

| EARTH GROUND | VIEW OF CONNECTOR ONPCBOARD | |

Return to Section

Return to Master

EN

+ S T U D | + S T U D |

|

|

|

|

| THIS D O C UME NT C O NTAINS PR | OP RIETARY INF | O RMATION O W NE D BY LINC OLN GLOBAL, INC. A | N D MAY N OT BE D UPLICATE D, COMMU NICATE | D | |||||||||||

PROPRIETARY & CONFIDENTIAL:TO OT HE R PARTIES O R USE D F O R ANY PU RP OSE WIT H O UT T HE EX PRESS W RITTE N PE RMISSION OF LIN C OLN GLOBAL, INC. |

|

|

|

|

| |||||||||||||||

UNLESS OTHERW ISE SPEC IF IE D TOLERAN | CE |

| DESIGN INFORM ATION |

| REFERENCE: |

| EQUIPMENT TYPE: |

| RANGER 305D |

|

| 2 | 2 |

|

| |||||

|

|

|

|

|

|

|

| |||||||||||||

MANUFAC | TURIN G TOLERANCE PER E205 | 6 |

|

|

|

|

|

|

| E | ||||||||||

ON 2 PLAC | E DECIMA LS IS ± .02 |

|

|

|

|

| L11946 |

|

|

|

|

| PA GE |

| O F ___ |

|

| |||

|

| DRAW N BY: | DEO |

|

|

|

|

|

|

|

| G | ||||||||

ON 3 PLACE DECIMALS IS ± .002 |

|

|

|

| SUBJECT: |

|

| MACHINE SCHEMATIC |

| DOCUMENT |

|

| DOCUMENTD | |||||||

ON ALL ANG LES IS ± .5 OF A DEGREE |

|

|

|

|

|

|

|

|

|

| NUMBER: |

|

| REVISION: | E | |||||

MA TERIA L TOL ERANCE (" t ") TO AGREE |

|

| ENGINEER: | BAM |

| SCALE: |

|

|

|

|

|

|

| |||||||

WITH PUB LISHED S TANDARDS. |

|

|

|

|

|

|

| MATERIAL |

| APPROVAL |

| PROJECT |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

DO NOT SCALE THIS DRAW ING |

| APPRO VED: | - |

| NONE |

| DISPOSITION: | UF | DATE: | 12/11/2003 | NUMBER: CRM3557 |

| L12212 |

| A |

| SIDOL | |||

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.