Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

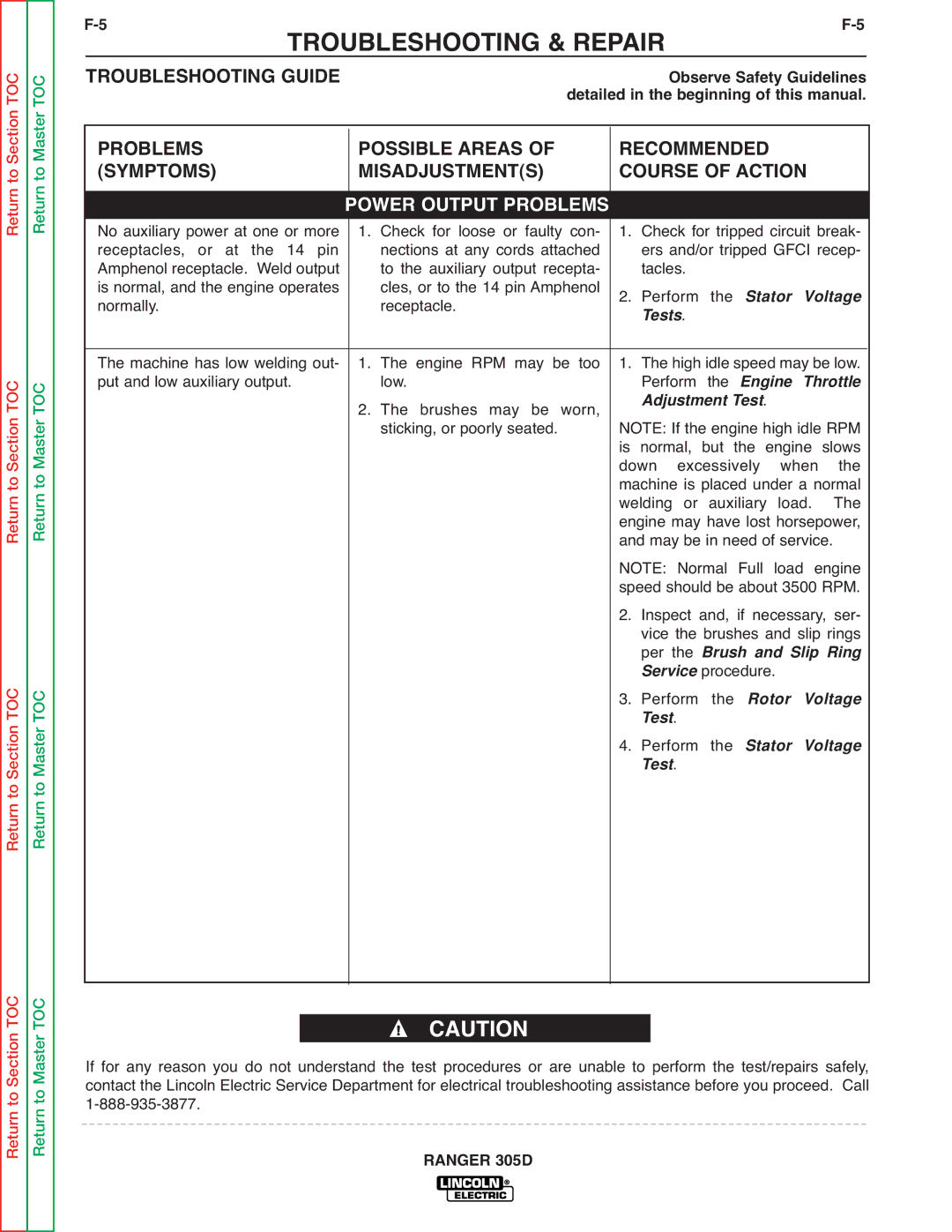

TROUBLESHOOTING & REPAIR |

| ||||

TROUBLESHOOTING GUIDE |

|

| Observe Safety Guidelines | ||

|

| detailed in the beginning of this manual. | |||

PROBLEMS |

| POSSIBLE AREAS OF | RECOMMENDED | ||

(SYMPTOMS) |

| MISADJUSTMENT(S) | COURSE OF ACTION | ||

|

| POWER OUTPUT PROBLEMS |

|

|

|

No auxiliary power at one or more | 1. Check for loose or faulty con- | 1. Check for tripped circuit break- | |||

receptacles, or at the 14 pin | nections at any cords attached | ers and/or tripped GFCI recep- | |||

Amphenol receptacle. Weld output | to the auxiliary output recepta- | tacles. |

| ||

is normal, and the engine operates | cles, or to the 14 pin Amphenol | 2. Perform the Stator Voltage | |||

normally. |

| receptacle. | Tests. |

| |

The machine has low welding out- | 1. The engine RPM may be too | 1. The high idle speed may be low. | |||

put and low auxiliary output. | low. | Perform | the Engine Throttle | ||

|

| 2. The brushes may be worn, | Adjus ment Test. | ||

|

| sticking, or poorly seated. | NOTE: If the engine high idle RPM | ||

|

|

| is normal, but the engine slows | ||

|

|

| down | excessively when the | |

|

|

| machine is placed under a normal | ||

|

|

| welding or auxiliary load. The | ||

|

|

| engine may have lost horsepower, | ||

|

|

| and may be in need of service. | ||

|

|

| NOTE: Normal Full load engine | ||

|

|

| speed should be about 3500 RPM. | ||

|

|

| 2. Inspect and, if necessary, ser- | ||

|

|

| vice the brushes and slip rings | ||

|

|

| S | vice procedure. | |

|

|

| per the | Brush and Slip Ring | |

|

|

| 3. Perform | the Rotor Voltage | |

|

|

| T st. |

| |

|

|

| 4. Perform the Stator Voltage | ||

|

|

| Test. |

| |

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call