Return to Section TOC

Return to Master TOC

THEORY OF OPERATION | ||||

| CHOPPER TECHNOLOGY |

|

| |

| FUNDAMENTALS |

| Hence the name “Chopper.” The biggest advantage of | |

| The new era of welding machines such as the Ranger | |||

| 305D employ a technology whereby a DC source is | chopper technology is the | ||

| turned on and off (chopped up) at high speed, then | arc, similar to the inverter machines. A block diagram | ||

| smoothed through an inductor to control an arc. | for this is as follows: |

| |

to Section TOC

Return to Master TOC

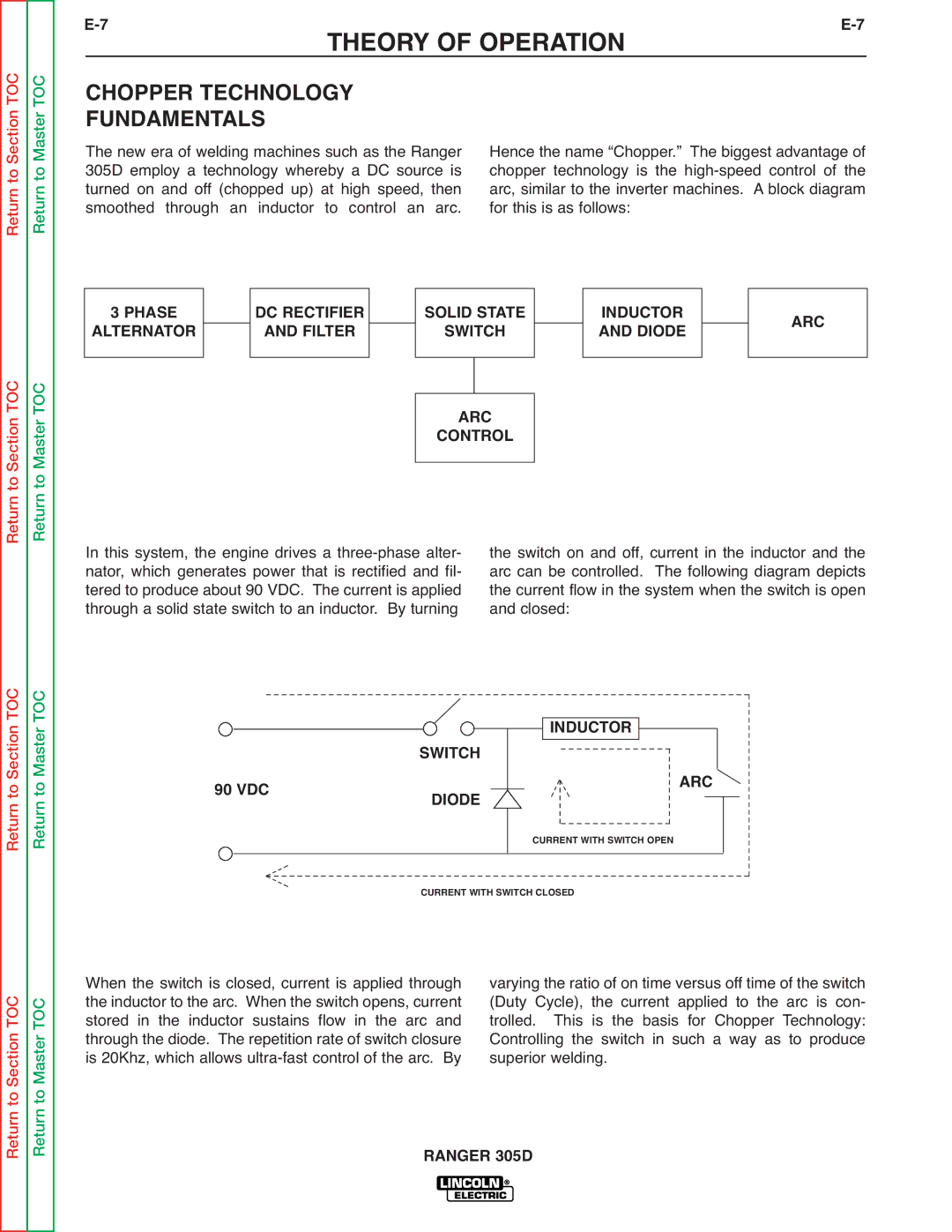

3PHASE ALTERNATOR

DC RECTIFIER

AND FILTER

SOLID STATE

SWITCH

ARC

CONTROL

INDUCTOR AND DIODE

ARC

Return

In this system, the engine drives a | the switch on and off, current in the inductor and the |

nator, which generates power that is rectified and fil- | arc can be controlled. The following diagram depicts |

tered to produce about 90 VDC. The current is applied | the current flow in the system when the switch is open |

through a solid state switch to an inductor. By turning | and closed: |

to Section TOC

to Master TOC

90 VDC | SWITCH |

DIODE |

INDUCTOR

ARC

Return

Return to Section TOC

Return

Return to Master TOC

CURRENT WITH SWITCH OPEN

CURRENT WITH SWITCH CLOSED

When the switch is closed, current is applied through | varying the ratio of on time versus off time of the switch | |

the inductor to the arc. When the switch opens, current | (Duty Cycle), | the current applied to the arc is con- |

stored in the inductor sustains flow in the arc and | trolled. This | is the basis for Chopper Technology: |

through the diode. The repetition rate of switch closure | Controlling the switch in such a way as to produce | |

is 20Khz, which allows | superior welding. | |