Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

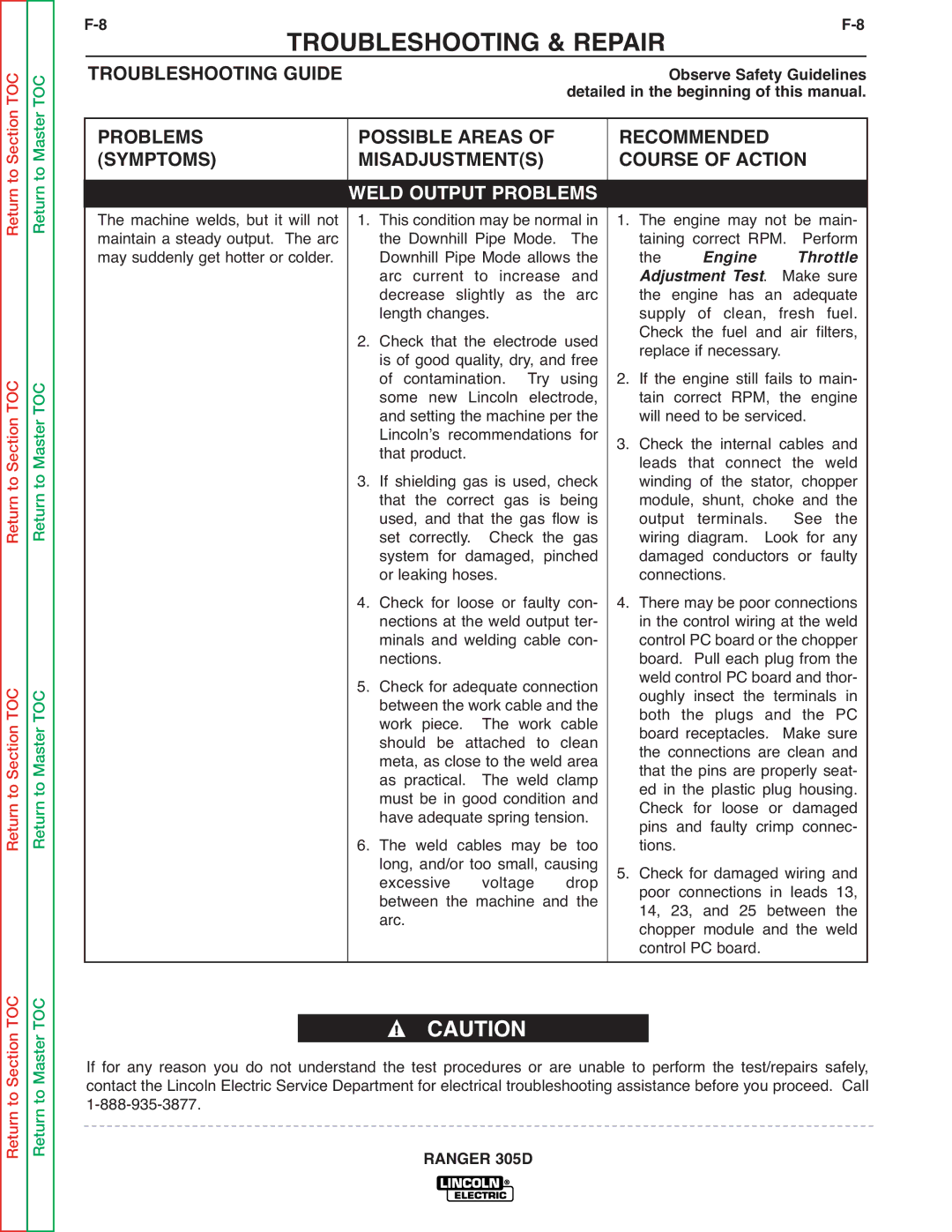

TROUBLESHOOTING & REPAIR |

|

|

|

| ||||||||||||||

| TROUBLESHOOTING GUIDE |

|

|

|

|

|

|

|

|

|

| Observe Safety Guidelines | ||||||

|

|

|

|

|

|

|

|

|

| detailed in the beginning of this manual. | ||||||||

| PROBLEMS |

|

| POSSIBLE AREAS OF |

| RECOMMENDED |

|

|

| |||||||||

|

|

|

|

|

|

| ||||||||||||

| (SYMPTOMS) |

|

| MISADJUSTMENT(S) |

| COURSE OF ACTION |

| |||||||||||

|

|

|

| WELD OUTPUT PROBLEMS |

|

|

|

|

|

|

|

| ||||||

| The machine welds, but it will not | 1. This condition may be normal in | 1. The engine may not be main- | |||||||||||||||

| maintain a steady output. The arc | the Downhill Pipe Mode. | The |

| taining correct RPM. | Perform | ||||||||||||

| may suddenly get hotter or colder. | Downhill Pipe Mode allows the |

| the |

| Engine |

| Throttle | ||||||||||

|

|

|

| arc current to increase and |

| Adjustment Test. | Make sure | |||||||||||

|

|

|

| decrease slightly as the arc |

| the engine has an adequate | ||||||||||||

|

|

|

| length changes. |

|

|

|

| supply of clean, fresh fuel. | |||||||||

|

|

|

| 2. Check that the electrode used |

| Check the fuel and air filters, | ||||||||||||

|

|

|

| is of good quality, dry, and free | 2. | replace if necessary. |

|

|

| |||||||||

|

|

|

| of contamination. | Try | using | If the engine still fails to main- | |||||||||||

|

|

|

| some new Lincoln electrode, |

| tain correct RPM, the engine | ||||||||||||

|

|

|

| and setting the machine per the |

| will need to be serviced. |

| |||||||||||

|

|

|

| Lincolnʼs recommendations for | 3. Check the internal cables and | |||||||||||||

|

|

|

| that product. |

|

|

|

|

| leads that connect the weld | ||||||||

|

|

|

| 3. If shielding gas is used, check |

| winding of the stator, chopper | ||||||||||||

|

|

|

| that the correct gas is being |

| module, shunt, choke and the | ||||||||||||

|

|

|

| used, and that the gas flow is |

| output | terminals. |

| See | the | ||||||||

|

|

|

| set correctly. | Check | the gas |

| wiring | diagram. Look for | any | ||||||||

|

|

|

| system for damaged, | pinched |

| damaged conductors | or faulty | ||||||||||

|

|

|

| or leaking hoses. |

|

|

| 4. | connections. |

|

|

| ||||||

|

|

|

| 4. Check for loose or faulty con- | There may be poor connections | |||||||||||||

|

|

|

| nections at the weld output ter- |

| in the control wiring at the weld | ||||||||||||

|

|

|

| minals and welding cable con- |

| control PC board or the chopper | ||||||||||||

|

|

|

| nections. |

|

|

|

|

| board. Pull each plug from the | ||||||||

|

|

|

| 5. Check for adequate connection |

| weld control PC board and thor- | ||||||||||||

|

|

|

|

| oughly insect the terminals in | |||||||||||||

|

|

|

| between the work cable and the |

| both the plugs and the PC | ||||||||||||

|

|

|

| work piece. | The | work | cable |

| board receptacles. | Make sure | ||||||||

|

|

|

| should be attached to clean |

| the connections are clean and | ||||||||||||

|

|

|

| meta, as close to the weld area |

| that the pins are properly seat- | ||||||||||||

|

|

|

| as practical. | The | weld | clamp |

| ed in the plastic plug housing. | |||||||||

|

|

|

| must be in good condition and |

| Check for loose or damaged | ||||||||||||

|

|

|

| have adequate spring tension. |

| pins and faulty crimp connec- | ||||||||||||

|

|

|

| 6. The weld cables may be too | 5. | tions. |

|

|

|

| ||||||||

|

|

|

| long, and/or too small, causing | Check for damaged wiring and | |||||||||||||

|

|

|

| excessive | voltage |

| drop |

| poor connections in leads 13, | |||||||||

|

|

|

| between the machine and the |

| 14, 23, and 25 between the | ||||||||||||

|

|

|

| arc. |

|

|

|

|

| chopper module and the weld | ||||||||

|

|

|

|

|

|

|

|

|

|

|

| control PC board. |

|

|

| |||

| If for any reason you do not |

|

|

| CAUTION |

|

|

|

| perform the test/repairs safely, | ||||||||

|

|

|

|

|

|

|

| |||||||||||

| understand the test procedures or are unable to | |||||||||||||||||

| contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call | |||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

| RANGER 305D |

|

|

|

|

|

|

|

|

|

| ||