Return to Section TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR | ||||

|

| STATOR/ROTOR REMOVAL AND REPLACEMENT (continued) |

| |

|

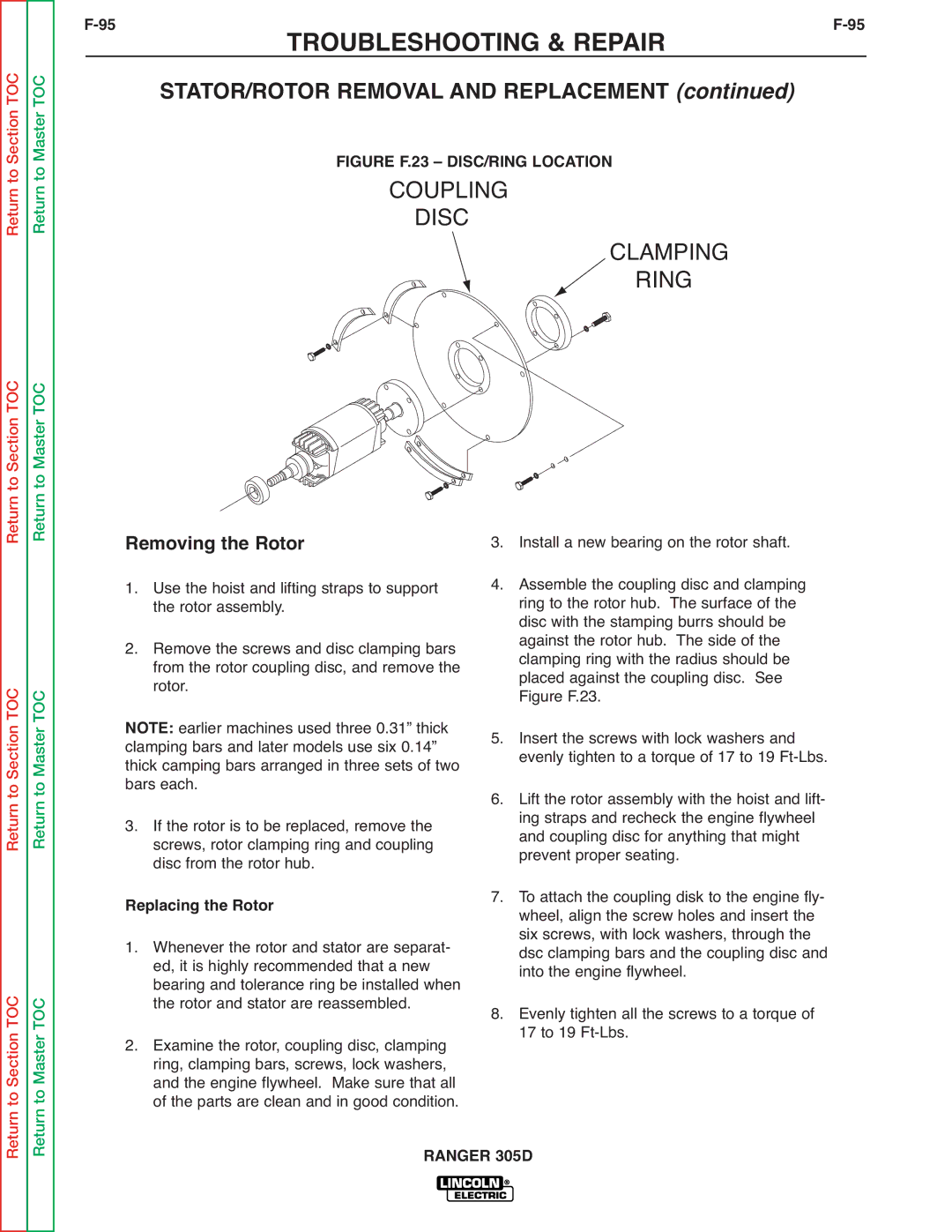

| FIGURE F.23 – DISC/RING LOCATION |

| |

|

| COUPLING |

|

|

|

| DISC | CLAMPING |

|

|

|

| RING |

|

Removing the Rotor

1.Use the hoist and lifting straps to support the rotor assembly.

2.Remove the screws and disc clamping bars from the rotor coupling disc, and remove the rotor.

NOTE: earlier machines used three 0.31” thick clamping bars and later models use six 0.14” thick camping bars arranged in three sets of two bars each.

3.If the rotor is to be replaced, remove the screws, rotor clamping ring and coupling disc from the rotor hub.

Replacing the Rotor

1.Whenever the rotor and stator are separat- ed, it is highly recommended that a new bearing and tolerance ring be installed when the rotor and stator are reassembled.

2.Examine the rotor, coupling disc, clamping ring, clamping bars, screws, lock washers, and the engine flywheel. Make sure that all of the parts are clean and in good condition.

3.Install a new bearing on the rotor shaft.

4.Assemble the coupling disc and clamping ring to the rotor hub. The surface of the disc with the stamping burrs should be against the rotor hub. The side of the clamping ring with the radius should be placed against the coupling disc. See Figure F.23.

5.Insert the screws with lock washers and evenly tighten to a torque of 17 to 19

6.Lift the rotor assembly with the hoist and lift- ing straps and recheck the engine flywheel and coupling disc for anything that might prevent proper seating.

7.To attach the coupling disk to the engine fly- wheel, align the screw holes and insert the six screws, with lock washers, through the dsc clamping bars and the coupling disc and into the engine flywheel.

8.Evenly tighten all the screws to a torque of 17 to 19

Return

Return