Return to Section TOC

Return to Master TOC

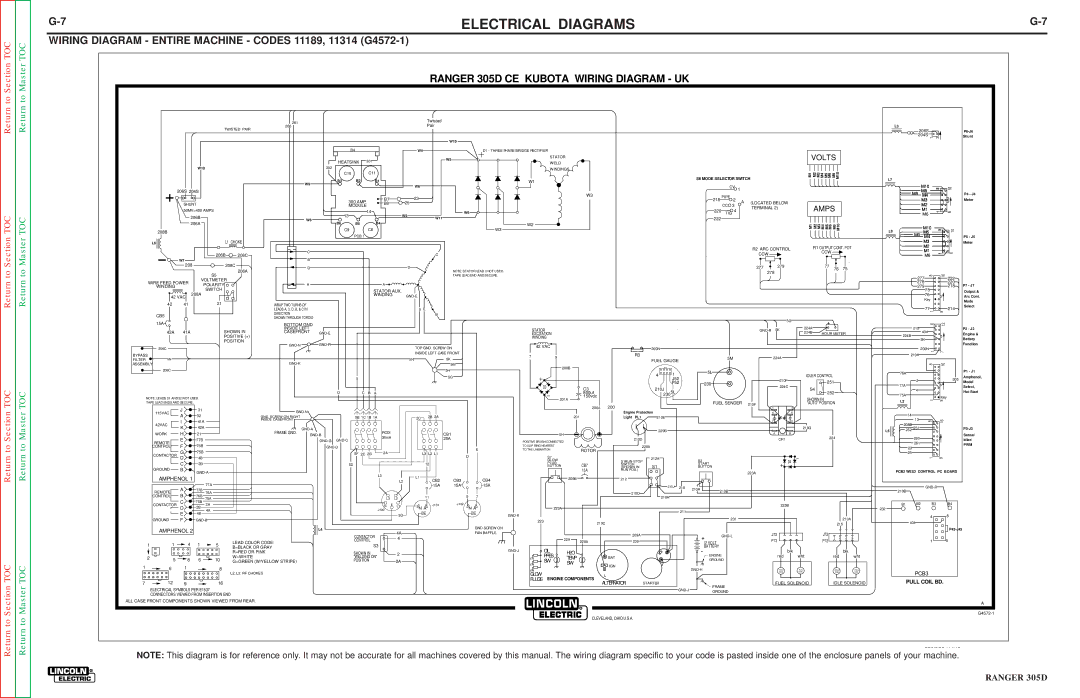

| ELECTRICAL DIAGRAMS | |

WIRING DIAGRAM - ENTIRE MACHINE - CODES 11189, 11314 |

|

|

|

| RANGER 305D CE KUBOTA WIRING DIAGRAM - UK |

| 260 261 | Twisted |

TWISTED PAIR | Pair | |

|

|

L3 | 206S |

|

| ||

| 204S | Shunt |

| 1 2 |

TOC

TOC

W10

206S 204S |

SHUNT |

50MV=400 AMPS |

206B |

206A |

208B |

L1 CHOKE |

|

|

|

| R4 |

|

|

| W10 |

|

|

|

| 301 |

|

| W4 | |

| 302 | HEATSINK |

|

| W5 | |||

|

| C10 | C11 |

|

| |||

|

|

|

|

| ||||

W9 |

| B3 |

| B2 |

| B1 |

|

|

|

|

|

|

|

|

| W6 | |

|

|

|

|

|

|

|

| |

|

|

| 300 AMP |

| B7 | 25 | 23 | |

|

|

|

| B8 |

| |||

|

|

| MODULE14 |

| W5 | W6 | ||

W8 |

|

| 13 |

|

|

| W11 | |

| B6 |

| B5 |

| B4 |

|

| |

|

| C9 | C8 |

|

| |||

|

|

| PCB 1 |

|

|

| ||

D1 - THREE PHASE BRIDGE RECTIFIER STATOR |

|

|

|

|

|

WELD |

|

|

|

|

|

WINDINGS |

|

|

|

|

|

W1 |

| S6 MODE SELECTOR SWITCH | |||

|

| CV | 1 | ||

| W3 |

| |||

| 218 | PIPE | 2 | A (LOCATED BELOW | |

|

| ||||

|

| 220 | CC | 3 | TERMINAL 2) |

|

| TIG | 4 |

| |

|

| 222 |

|

|

|

W3 | W2 |

|

VOLTS

M1 M2 M3M4 M5M6 M9M10 AMPS

M1M2M3M4M5M6M9M10

L7 |

| M10 |

|

|

|

| 5 | 10 | |

| M9 | M5 |

|

|

| M4 |

| P4 - J4 | |

|

| M3 |

| Meter |

|

| M2 |

|

|

|

| M1 | 1 | 6 |

|

| M6 |

|

|

|

| M10 | 10 | |

L8 | M9 | M5 | 5 | |

| M4 |

| P5 - J5 | |

|

| M3 |

|

|

Return to Section

Return to Section TOC

Section TOC

Return to Master

Return to Master TOC

Master TOC

| L6 |

|

|

|

|

|

| |

|

|

| W7 208 |

|

| 206B | 206C | |

|

|

|

|

| 208C | 206A | ||

|

|

|

|

|

| S5 | ||

WIRE FEED POWER | VOLTMETER |

| ||||||

POLARITY |

| |||||||

|

| WINDING |

|

|

| |||

|

| 42 VAC | 208A | SWITCH |

| |||

|

| 42 | 41 |

|

| 21 |

| |

|

| CB5 |

|

|

|

|

|

|

|

| 15A | 41A |

|

| SHOWN IN | ||

|

| 42A |

|

| ||||

|

|

|

|

|

|

| POSITIVE (+) | |

|

| 206C |

|

|

|

| POSITION | |

BYPASS |

|

|

|

|

|

|

| |

| 5N |

|

|

|

|

|

| |

FILTER |

|

|

|

|

|

|

| |

ASSEMBLY | 208C |

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

NOTE: LEADS 31 AND32 NOT USED. |

|

|

| |||||

TAPE LEAD ENDS AND SECURE. |

|

|

|

| ||||

|

| 115VAC | J |

| 31 |

|

|

|

|

| A |

| 32 |

|

|

| |

|

| 42VAC | I |

| 41A |

|

|

|

|

| K |

| 42A |

|

|

| |

|

| WORK | H |

| 21 |

|

|

|

|

| REMOTE | E |

| 77B |

|

|

|

|

| F |

| 76B |

|

|

| |

| CONTROL |

|

|

|

| |||

|

| CONTACTOR | G |

| 75B |

|

|

|

|

| D |

| 4B |

|

|

| |

|

| GROUND | C |

| 2B |

|

|

|

|

| B |

|

|

| |||

|

| AMPHENOL 1 |

|

| ||||

|

|

| A |

| 77B | 77A |

|

|

|

| REMOTE |

| 76A |

|

| ||

| CONTROL | B |

| 76B | 75A |

|

| |

|

| CONTACTOR | C |

| 75B | 2A |

|

|

|

|

| D |

| 2B | 4A |

|

|

|

| GROUND | E |

| 4B |

|

|

|

|

| F |

|

|

| |||

|

| AMPHENOL 2 |

|

|

|

| ||

1 |

| 1 |

| 4 | 1 |

| 5 |

|

1 2 |

| 6 5 | 18 | 6 |

| 108 |

| |

7 |

| 12 | 9 |

|

|

| 16 |

|

| ELECTRICAL SYMBOLS PER E1537 |

|

| |||||

| CONNECTORS VIEWED FROM INSERTION END |

| ||||||

ALL CASE FRONT COMPONENTS SHOWN VIEWED FROM REAR.

| C |

|

|

|

|

|

|

|

|

|

|

|

| C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| R2 ARC CONTROL |

| R1 OUTPUT CONT. POT |

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CCW |

|

|

|

|

| CCW |

|

|

| ||||

| B |

|

|

|

|

|

|

|

| D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 277 |

|

| 279 |

|

|

|

| 77 |

|

|

| |

| D |

|

|

|

|

|

|

|

|

|

|

|

| NOTE: STATOR LEAD 3 NOT USED. |

|

|

|

|

|

|

|

|

|

|

|

| 278 |

|

|

|

| 76 | 75 |

| |||||||

| A |

|

|

|

|

|

| A |

|

|

|

|

|

|

| TAPE LEAD END ANDSECURE. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| STATOR AUX. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

| WINDING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

WRAP TWO TURNS OF |

|

|

|

|

|

|

|

|

|

| 5 | E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

LEADS A, 3, D, B, & C IN |

|

|

|

|

|

|

|

|

|

| B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

DIRECTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

SHOWN THROUGH TOROID |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 5G |

|

|

|

|

|

|

| ||

BOTTOM GND |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| STATOR |

|

|

|

|

|

|

|

|

|

|

| 5K | 224A |

|

| + |

|

|

| |||||

INSIDE LEFT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| HOUR METER |

| ||||||||||

CASEFRONT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| EXCITATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 224B |

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| WINDING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| TOP GND. SCREW ON |

|

| 42 VAC |

|

|

| 200N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

| 5N | INSIDE LEFT CASE FRONT |

|

| 7 | 9 |

| R3 | FUEL GAUGE |

|

|

| 5M |

|

| 224A |

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

| 5K | 5M |

|

|

| 200B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 5H |

|

|

|

|

|

| 4 | 1 |

|

| 5L |

|

|

|

|

|

| IDLER CONTROL |

|

|

| |||||

|

|

|

|

| 5 |

|

|

|

|

|

|

|

|

| 5G |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| J52 |

|

| 230 |

|

|

|

| 210F |

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| D3 |

| C3 |

|

| 210J | P52 |

|

|

|

|

| S4 |

| 251 |

|

| ||||||

|

|

|

| D |

| C B | A |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 5L |

|

|

|

|

|

|

| 224C |

| 252 |

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 201A | 800uf |

|

| 230 |

|

|

|

|

|

|

|

|

| SHOWN IN |

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 150vdc |

|

|

|

|

| FUEL SENDER 210F |

| 1 |

| 3 |

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 200A 200 |

|

|

|

|

|

|

|

| "AUTO" POSITION |

|

| |||||||||||

|

|

| 5B 1C 1B 1A |

|

|

|

| 2C | 2B 2A |

|

|

|

|

| 201 |

| Engine Protection | 210E |

|

|

|

|

|

|

| 4 |

| 6 |

|

|

|

|

|

|

| ||||||

GND. SCREW ON RIGHT |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Light PL1 |

|

|

|

|

|

|

|

| 7 |

| 9 |

|

|

|

|

|

|

| ||||||||

INSIDE CASEFRONT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 210G |

|

|

|

|

|

| |||||

FRAME GND. |

|

|

|

|

| RCDI |

|

|

|

|

|

| CB1 |

|

|

| 5H |

|

|

| 229B |

|

|

|

|

|

|

| A |

| B |

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| 210D |

|

|

|

|

|

|

|

| CR1 |

|

|

| 224 |

|

| ||||||||||||

|

|

|

|

|

| 30mA |

|

|

|

|

| 20A |

|

|

| POSITIVE BRUSH CONNECTED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

| 5F | 2C 2B |

| 2A |

|

|

|

| L3 L2 L1 |

|

| E |

| TO SLIP RING NEAREST | ROTOR | 229A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

| D |

| TO THE LAMINATION |

|

| 212A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| S7 |

|

|

|

| S2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

| 12 |

|

|

|

|

| GLOW |

|

|

|

|

|

|

|

|

| D4 |

|

|

|

|

|

|

| |||||

|

|

|

|

| 5D |

|

|

|

|

|

|

|

|

|

|

|

| PLUG | CB7 | SWITCH | S1 |

|

| START |

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| BUTTON | (SHOWN IN |

|

| BUTTON |

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| L3 |

|

|

| L1 |

|

|

|

|

|

|

| 209B | 15A | RUN POS.) |

|

|

|

|

|

|

| 223A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| L2 |

|

| CB2 |

| CB3 | CB4 |

|

| 212 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 210J | 210 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| 15A |

| 15A | 15A |

|

|

|

| 210D |

| 210A |

| 210B |

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

| L3 |

| L2 |

|

| 11 |

|

| 9 | 7 |

|

|

|

|

| 210H |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| E |

|

| J101 |

| J102 | N A |

|

| 223A |

|

|

|

|

|

|

|

|

|

|

| 225B |

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

| J100N |

| L1 |

| N A |

|

|

|

|

|

|

|

|

| 211 |

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

| 5D |

|

| E |

|

|

| E | 223 |

| 210C |

|

|

|

|

|

| 231 |

|

|

|

|

|

|

|

|

| 215210A |

| |||

|

|

| L4 |

|

|

|

|

|

|

|

|

|

|

|

|

| GND SCREW ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

| CONTACTOR |

|

| 4A |

|

|

|

|

|

| FAN BAFFLE. |

|

| 229 | 229A | 209A |

|

|

|

| +12 VOLT |

|

| J73 |

|

|

| J72 | 1 2 | 3 4 |

| ||||||

|

|

|

|

| CONTROL | S3 |

| 4 |

|

|

|

|

|

|

|

|

| 209 |

|

|

|

|

|

|

| P73 |

|

|

| P72 |

| ||||||||||

|

|

|

|

| SHOWN IN |

| 2 |

|

|

|

|

|

|

| OIL | H2O | BAT |

|

|

|

|

| - | BATTERY |

|

|

|

| red | blk | wht |

|

|

| red | blk | wht | ||||

|

|

|

|

| "WELDING ON" |

|

|

|

|

|

|

|

|

|

| PRES | TEMP |

|

|

|

|

|

| ENGINE |

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

| POSITION |

|

|

| 2A |

|

|

|

|

|

|

|

| SW | SW | IGN |

|

|

|

|

| GROUND |

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| HOLD |

| PULL |

|

|

| HOLD |

| PULL | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| L |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| GLOW |

|

|

|

|

|

|

|

|

|

|

| COIL |

| COIL |

|

|

| COIL |

| COIL | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| STARTER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PLUGS ENGINE COMPONENTS |

|

|

|

| FRAME |

|

|

| FUEL SOLENOID |

|

|

| IDLE SOLENOID | |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ALTERNATOR |

|

|

|

|

|

|

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| GROUND |

|

|

|

|

|

|

|

|

|

|

|

| |||

![]() R

R

|

|

| M2 |

|

| Meter |

|

|

| M1 | 1 6 |

| |

|

|

| M6 |

|

|

|

|

|

| 8 | 16 | 222 |

|

|

| 277 |

|

| ||

|

| 278 |

| 220 | P7 - J7 | |

|

| 279 75 |

| 218 | ||

|

|

| Output & | |||

|

|

| 76 |

|

| Arc Cont. |

|

|

| Key |

| 214 | Mode |

|

|

| 77 |

| Select | |

|

|

| 1 9 |

|

| |

|

| 215 | 6 | 12 |

| P2 - J2 |

| 224B | 404 |

|

| ||

|

|

|

| Engine & | ||

|

| 5K |

|

| Battery | |

|

|

|

|

| ||

|

|

| 200N |

|

| Function |

| 210H | 7 |

|

| ||

| 1 |

|

| |||

|

|

|

|

| ||

| 76A |

| 8 | 16 |

|

|

|

|

|

| 305 | P1 - J1 | |

| 2 |

|

| Amphenol, | ||

| 77A |

|

| |||

|

|

| Model | |||

| 4 |

|

|

| Select, | |

| 75A |

| Key | Hot Start | ||

|

| 1 |

| |||

| L2 |

| 9 |

|

| |

|

|

|

|

|

| |

| 14 | 13 | 8 | 16 |

|

|

| 208B | 251 |

|

|

|

|

L5 | 252 |

|

|

| ||

|

| 260 |

|

|

| Sense/ |

|

|

|

|

| Idler/ | |

| 23 261 |

|

|

| PWM | |

| 25 |

| 1 9 |

|

| |

| PCB2 WELD CONTROL PC BOARD |

| ||||

| 210B |

|

|

| ||

|

|

|

|

|

| |

232 | B1 | B2 | B3 | B4 |

| |

|

| 4 |

| 8 |

| |

| 404 |

|

| |||

|

|

|

|

| ||

|

|

|

|

|

| |

|

|

| 1 |

| 5 |

|

PCB3

PULL COIL BD.

A

Return to

Return to

CLEVELAND, OHIO U.S.A.

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The wiring diagram specific to your code is pasted inside one of the enclosure panels of your machine.

PRINT TO 11 X 17

RANGER 305D