Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

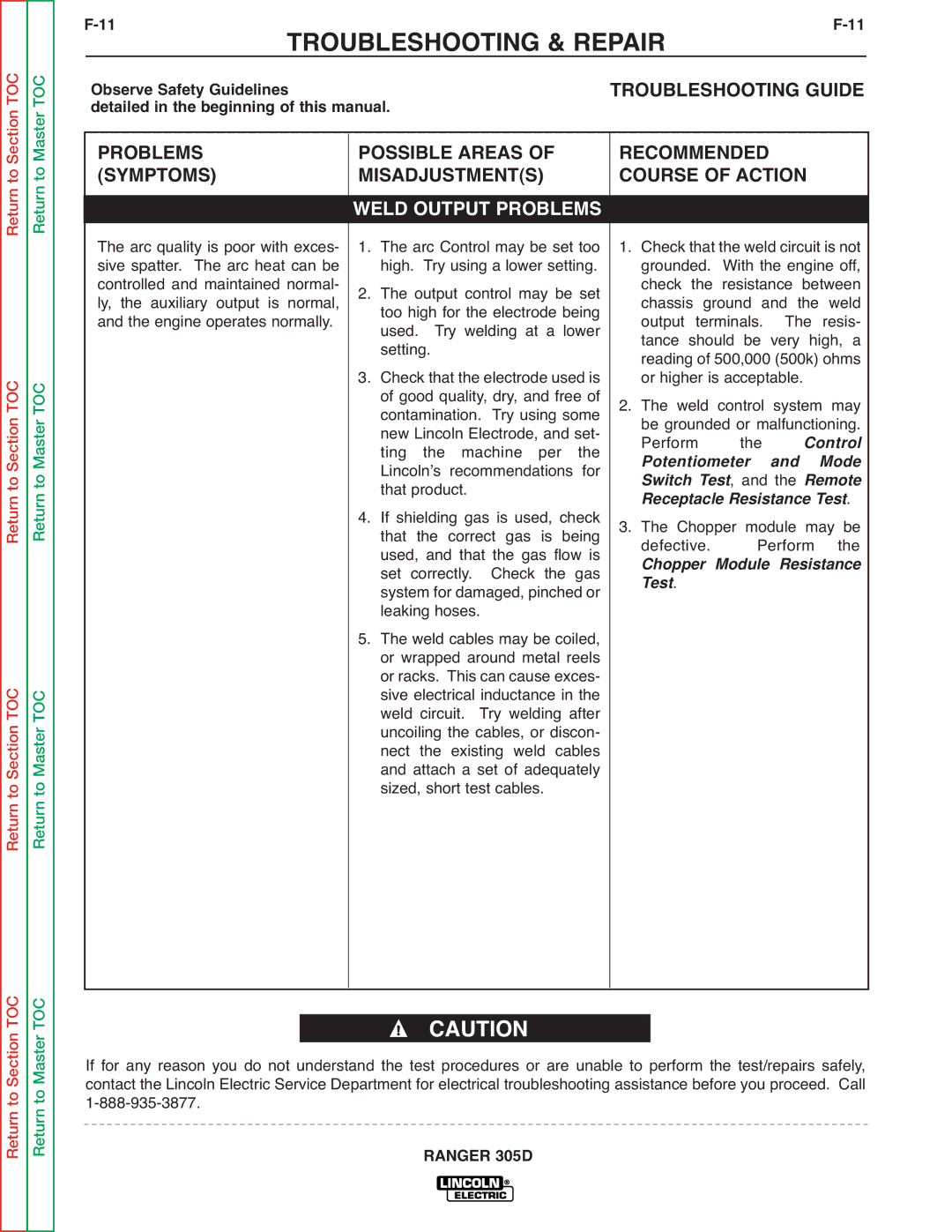

TROUBLESHOOTING & REPAIR |

|

|

|

|

| ||||||

| Observe Safety Guidelines |

|

| TROUBLESHOOTING GUIDE |

| ||||||

| detailed in the beginning of this manual. |

| |||||||||

| PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

|

|

|

| ||||

| (SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION |

|

| ||||||

|

|

| WELD OUTPUT PROBLEMS |

|

|

|

|

|

|

| |

| The arc quality is poor with exces- | 1. | The arc Control may be set too | 1. Check that the weld circuit is not |

| ||||||

| sive spatter. | The arc heat can be |

| high. Try using a lower setting. | grounded. | With the engine off, |

| ||||

| controlled and maintained normal- | 2. | The output control may be set | check the | resistance | between |

| ||||

| ly, the auxiliary output is normal, | chassis ground and the weld |

| ||||||||

| and the engine operates normally. |

| too high for the electrode being | output terminals. | The | resis- |

| ||||

|

|

|

| used. Try welding at a lower | tance should be very high, a |

| |||||

|

|

|

| setting. | reading of 500,000 (500k) ohms |

| |||||

|

|

| 3. Check that the electrode used is | or higher is acceptable. |

|

| |||||

|

|

|

| of good quality, dry, and free of | 2. The weld control system may |

| |||||

|

|

|

| contamination. Try using some | be grounded or malfunctioning. |

| |||||

|

|

|

| new Lincoln Electrode, and set- | Perform | the |

| Control |

| ||

|

|

|

| ting the machine per the | Potentiometer | and |

| Mode |

| ||

|

|

|

| Lincolnʼs recommendations for | Switch Test, and the | Remote |

| ||||

|

|

| 4. | that product. | Receptacle Resistance Test. |

| |||||

|

|

| If shielding gas is used, check | 3. The Chopper module may be |

| ||||||

|

|

|

| that the correct gas is being | defective. | Perform | the |

| |||

|

|

|

| used, and that the gas flow is | Chopper Module Resistance |

| |||||

|

|

|

| set correctly. Check the gas | Test | . |

|

|

|

|

|

|

|

|

| system for damaged, pinched or |

|

|

|

|

|

| |

|

|

|

| leaking hoses. |

|

|

|

|

|

|

|

|

|

| 5. The weld cables may be coiled, |

|

|

|

|

|

|

| |

|

|

|

| or wrapped around metal reels |

|

|

|

|

|

|

|

|

|

|

| or racks. This can cause exces- |

|

|

|

|

|

|

|

|

|

|

| sive electrical inductance in the |

|

|

|

|

|

|

|

|

|

|

| weld circuit. Try welding after |

|

|

|

|

|

|

|

|

|

|

| uncoiling the cables, or discon- |

|

|

|

|

|

|

|

|

|

|

| nect the existing weld cables |

|

|

|

|

|

|

|

|

|

|

| and attach a set of adequately |

|

|

|

|

|

|

|

|

|

|

| sized, short test cables. |

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call