Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

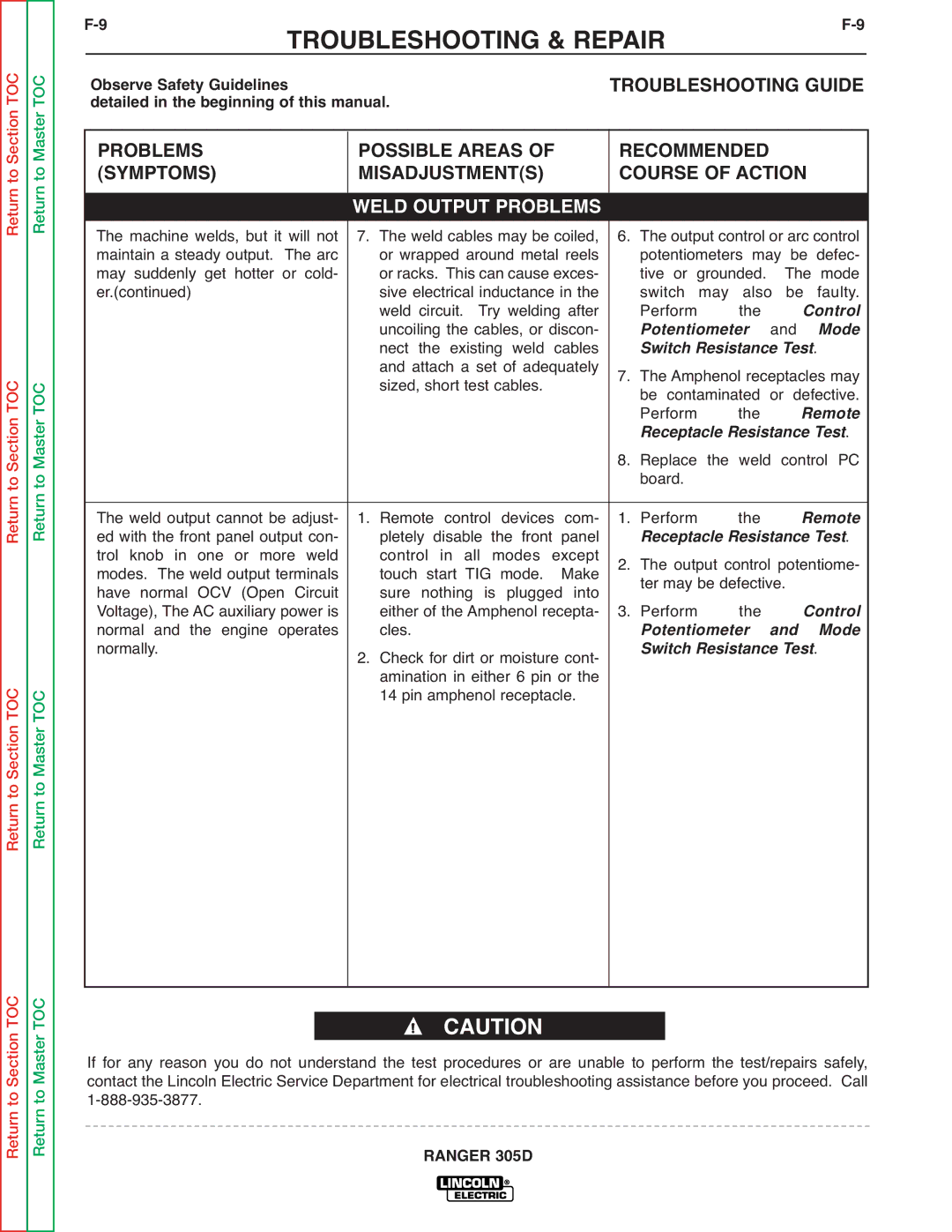

TROUBLESHOOTING & REPAIR |

|

|

|

| |||||||

| detailed in the beginning of this manual. | TROUBLESHOOTING GUIDE |

| ||||||||

| Observe Safety Guidelines |

|

|

|

|

|

|

|

|

| |

| PROBLEMS |

| POSSIBLE AREAS OF | RECOMMENDED |

|

|

|

| |||

| (SYMPTOMS) |

| MISADJUSTMENT(S) | COURSE OF ACTION |

|

| |||||

|

|

| WELD OUTPUT PROBLEMS |

|

|

|

|

|

|

| |

| The machine welds, but it will not | 7. | The weld cables may be coiled, | 6. | The output control or arc control |

| |||||

| maintain a steady output. The arc |

| or wrapped around metal reels |

| potentiometers may be defec- |

| |||||

| may suddenly get hotter or cold- |

| or racks. This can cause exces- |

| tive or grounded. | The | mode |

| |||

| er.(continued) |

|

| sive electrical inductance in the |

| switch may also be faulty. |

| ||||

|

|

|

| weld circuit. Try welding after |

| Perform | the | and | Control |

| |

|

|

|

| uncoiling the cables, or discon- |

| Potentiometer |

| Mode |

| ||

|

|

|

| nect the existing weld cables | 7. | Switch Resistan | Test. |

|

| ||

|

|

|

| and attach a set of adequately | The Amphenol receptacles may |

| |||||

|

|

|

| sized, short test cables. |

| be contaminated | or defective. |

| |||

|

|

|

|

|

| Perform | the |

| Remote |

| |

|

|

|

|

| 8. | ceptacle Resistance Test. |

| ||||

|

|

|

|

| Replace | the weld control PC |

| ||||

|

|

|

|

|

| board. |

|

|

|

|

|

| The weld output cannot be adjust- | 1. Remote control devices com- | 1. | Perform | the |

| Remote |

| |||

| ed with the front panel output con- |

| pletely disable the front panel |

| Receptacle Resistance Test. |

| |||||

| trol knob in one or more weld |

| control in all modes except | 2. | The output control potentiome- |

| |||||

| modes. The weld output terminals |

| touch start TIG mode. Make |

| |||||||

| have normal OCV (Open Circuit |

| sure nothing is plugged into | 3. | ter may be defective. |

|

|

| |||

| Voltage), The AC auxiliary power is |

| either of the Amphenol recepta- | Perform | the |

| Control |

| |||

| normal and the engine operates | 2. | cles. |

| Potentiometer | and |

| Mode |

| ||

| normally. |

| Check for dirt or moisture cont- |

| Switch Resistance Test. |

|

| ||||

|

|

|

| amination in either 6 pin or the |

|

|

|

|

|

|

|

|

|

|

| 14 pin amphenol receptacle. |

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call