Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

ACCESSORIES |

|

|

|

|

|

|

|

|

| ||||||||

| K18161 FULL KVA ADAPTER KIT | 2. | Connect the electrode cable from the wire feeder to | ||||||||||||||

| Plugs into the 120/240V NEMA |

| the “+” terminal of the welder. | Connect the work | |||||||||||||

| the casefront (which accepts |

| cable to the | ||||||||||||||

| verts it to a NEMA | NOTE: Welding cable must be sized for current and | |||||||||||||||

| prong plugs.) |

|

| duty cycle of application. |

| ||||||||||||

| CONNECTION OF LINCOLN | 3. Connect the K867 Universal Adapter to the | |||||||||||||||

|

| amphenol of the Ranger 305D as shown in Figure | |||||||||||||||

|

| C.1. Make the proper connections for local or | |||||||||||||||

| ELECTRIC WIRE FEEDERS |

| remote control according to Figure C.1. and the fol- | ||||||||||||||

|

|

| WARNING |

|

| lowing NOTES, indicated on the figure: | |||||||||||

|

|

|

|

| TO | 2 |

|

|

|

|

|

|

| TO | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| WIRE | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

| ELECTRIC SHOCK can kill. |

| K867 |

| 4 |

|

|

|

|

|

|

| FEEDER | ||||

|

|

|

|

|

|

|

|

|

| ||||||||

. | Do not operate with panels open. |

| A. These leads are not used for the Ranger | ||||||||||||||

. | Disconnect NEGATIVE |

| 305D. Insulate each unused lead individually. | ||||||||||||||

|

| LEAD before servicing. |

| B. For wire feeders that return a signal for weld- | |||||||||||||

|

| . Do not touch electrically live parts. |

| ing output, use an isolation relay to close | |||||||||||||

|

|

| leads 2 and 4. |

| |||||||||||||

| MOVING PARTS can injure. |

| C. Refer to the | Operation section of this manual | |||||||||||||

|

| for maximum wire feeder auxiliary current | |||||||||||||||

. | Keep guards in place. | 4. | draw. |

|

|

|

|

|

|

|

|

|

| ||||

. | Keep away from moving parts. | Set the “MODE” switch to the | |||||||||||||||

. | Only qualified personnel should | 5. | Place the “IDLER” switch in the “AUTO” position. | ||||||||||||||

|

| install, use or service this equipment. |

|

| CAUTION | ||||||||||||

|

| ||||||||||||||||

Any increase of the high idle engine RPM by chang- | |||||||||||||||||

| CONNECTION OF THE RANGER 305D TO | ||||||||||||||||

| ing the governor setting or overriding the throttle link- | ||||||||||||||||

| WIRE FEEDERS USING K867 UNIVERSAL | age will cause an increase in the AC auxiliary voltage. | |||||||||||||||

| ADAPTER (SEE FIGURE C.1) | If this voltage goes over 140 volts, wire feeder control | |||||||||||||||

| NOTE: When you use the Ranger 305D with non- | circuit may be damaged. The engine governor setting | |||||||||||||||

| Lincoln Electric wire feeders or with certain earlier | is preset at the factory - do not adjust above RPM | |||||||||||||||

| models of Lincoln wire feeders, you will require the | specifications listed in this manual. |

| ||||||||||||||

| K867 Universal Adapter. The following discussion and | ||||||||||||||||

| connection diagram explain in general how to make the | 6. | Set the “VOLTMETER” switch to “+” or | ||||||||||||||

| proper connections. |

| ing on the polarity chosen. |

| |||||||||||||

| 1. Shut the welder off. | 7. Set the ARC control to “0” initially and adjust to suit. | |||||||||||||||

| 8. | Adjust wire feed speed at the wire feeder. | |||||||||||||||

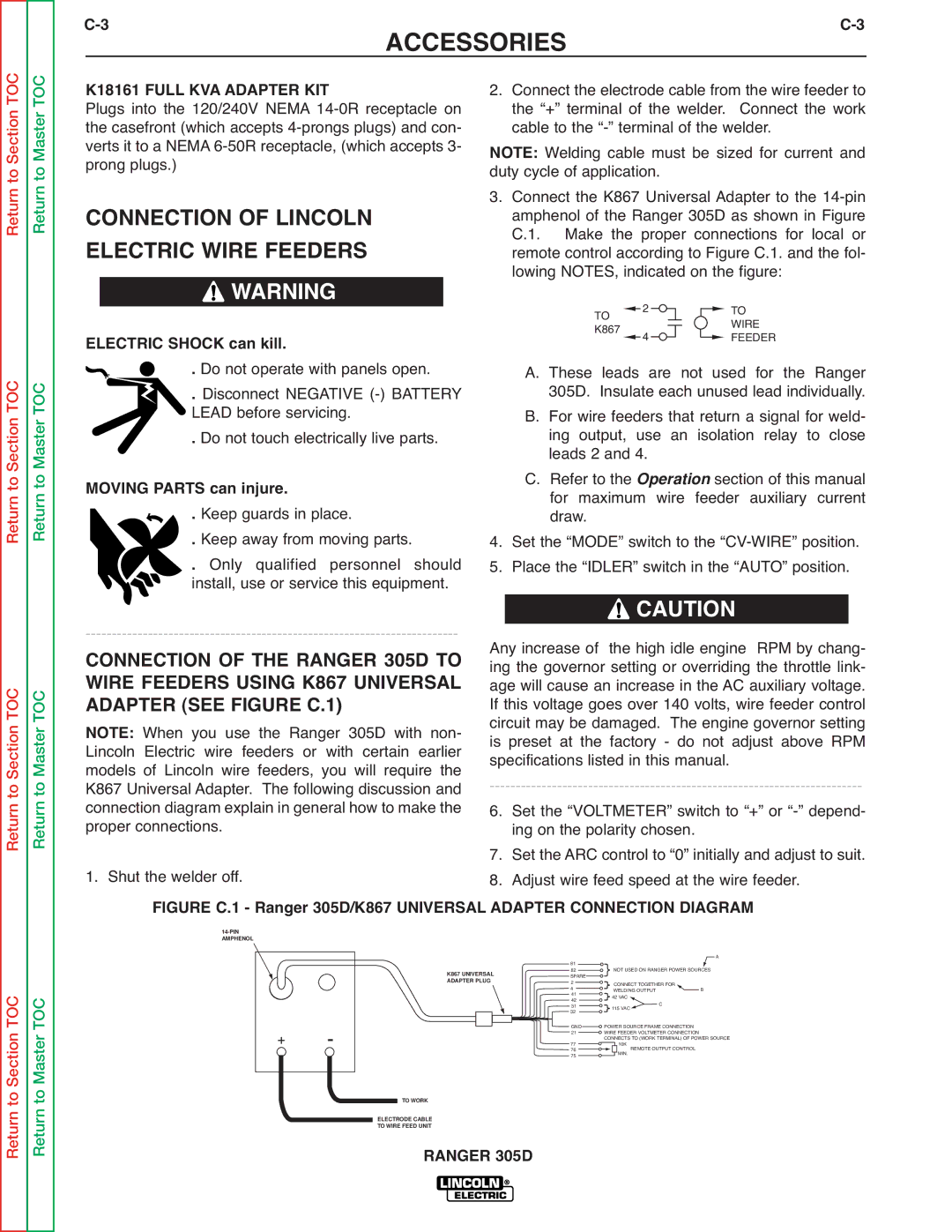

FIGURE C.1 - Ranger 305D/K867 UNIVERSAL ADAPTER CONNECTION DIAGRAM

Return to Section TOC

Return to Master TOC

+ -

| 81 |

|

| A |

K867 UNIVERSAL | 82 | NOT USED ON RANGER POWER SOURCES | ||

| SPARE | CONNECT TOGETHER FOR |

| |

ADAPTER PLUG | 2 |

| ||

4 | WELDING OUTPUT | B | ||

| 41 | |||

| 42 | 42 VAC | C |

|

| 31 | 115 VAC |

| |

| 32 |

|

| |

| GND | POWER SOURCE FRAME CONNECTION |

| |

| 21 | WIRE FEEDER VOLTMETER CONNECTION |

| |

| 77 | CONNECTS TO (WORK TERMINAL) OF POWER SOURCE | ||

| 10K | REMOTE OUTPUT CONTROL |

| |

| 76 | MIN. |

| |

| 75 |

|

| |

TO WORK

ELECTRODE CABLE

TO WIRE FEED UNITRANGER 305D