Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

| OPERATION |

| |||||

TIG WELDING |

| ARC GOUGING |

|

|

| ||

The TOUCH START TIG setting of the MODE switch is for DC | The RANGER 305D can be used for limited arc goug- | ||||||

TIG (Tungsten Inert Gas) welding. To initiate a weld, the OUT- | ing. For optimal performance, set the MODE switch to | ||||||

PUT control is first set to the desired current and the tungsten is | |||||||

touched to the work. During the time the tungsten is touching the | Set the OUTPUT CONTROL knob to adjust output cur- | ||||||

work there is very little voltage or current and, in general, no | |||||||

tungsten contamination. Then the tungsten is gently lifted off the | rent to the desired level for the gouging electrode being | ||||||

work in a rocking motion, which establishes the arc. |

| used according to the ratings in the following Table B.3 | |||||

The ARC CONTROL is not active in the TIG mode. |

|

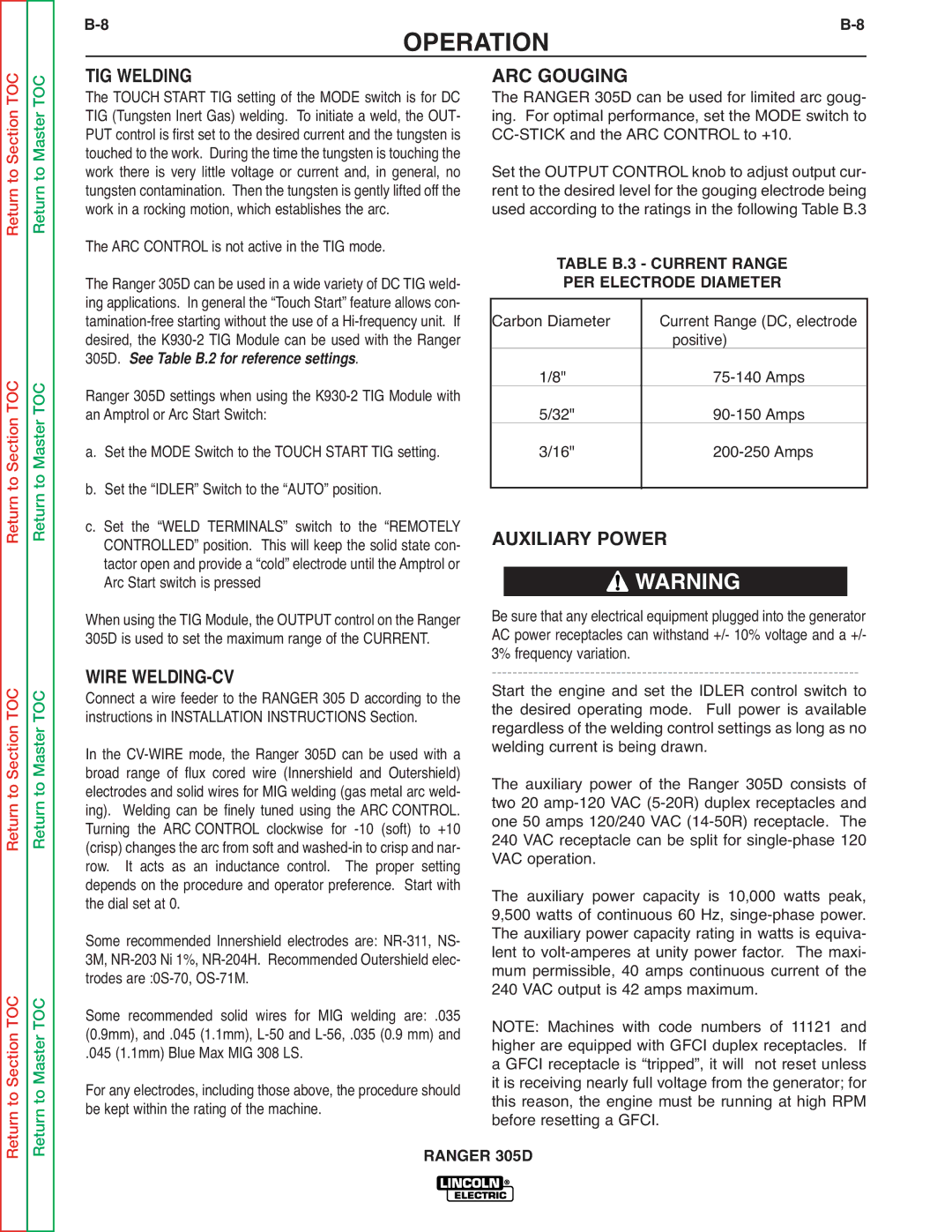

| TABLE B.3 - CURRENT RANGE | ||||

The Ranger 305D can be used in a wide variety of DC TIG weld- |

| PER ELECTRODE DIAMETER | |||||

ing applications. In general the “Touch Start” feature allows con- |

|

|

|

|

| ||

Carbon Diameter |

| Current Range (DC, electrode | |||||

| |||||||

desired, the |

|

|

| positive) | |||

Ranger 305D settings when using the | 1/8" |

| |||||

305D. | See Table B.2 for reference settings. |

|

|

|

|

|

|

an Amptrol or Arc Start Switch: |

|

|

|

|

|

| |

| 5/32" |

| |||||

a. Set the MODE Switch to the TOUCH START TIG setting. | 3/16" |

| |||||

b. Set the “IDLER” Switch to the “AUTO” position. |

|

|

|

|

|

| |

|

|

|

|

|

| ||

c. Set the “WELD TERMINALS” switch to the “REMOTELY | AUXILIARY POWER | ||||||

CONTROLLED” position. This will keep the solid state con- | |||||||

tactor open and provide a “cold” electrode until the Amptrol or |

|

|

|

|

| ||

Arc Start switch is pressed |

|

|

| WARNING |

| ||

When using the TIG Module, the OUTPUT control on the Ranger | Be sure that any electrical equipment plugged into the generator | ||||||

305D is used to set the maximum range of the CURRENT. | AC power receptacles can withstand +/- 10% voltage and a +/- | ||||||

3% frequency variation. |

|

|

| ||||

WIRE |

| Start the engine and set the IDLER control switch to | |||||

Connect a wire feeder to the RANGER 305 D according to the | |||||||

the desired operating mode. Full power is available | |||||||

instructions in INSTALLATION INSTRUCTIONS Section. | regardless of the welding control settings as long as no | ||||||

In the | welding current is being drawn. | ||||||

broad range of flux cored wire (Innershield and Outershield) | The auxiliary power of the Ranger 305D consists of | ||||||

electrodes and solid wires for MIG welding (gas metal arc weld- | |||||||

ing). Welding can be finely tuned using the ARC CONTROL. | two 20 | ||||||

Turning the ARC CONTROL clockwise for | one 50 amps 120/240 VAC | ||||||

(crisp) changes the arc from soft and | 240 VAC receptacle can be split for | ||||||

row. | It acts as an inductance control. The proper setting | VAC operation. |

|

|

| ||

depends on the procedure and operator preference. Start with | The auxiliary power capacity is 10,000 watts peak, | ||||||

the dial set at 0. |

| 9,500 watts of continuous 60 Hz, | |||||

Some recommended Innershield electrodes are: | The auxiliary power capacity rating in watts is equiva- | ||||||

lent to | |||||||

3M, | mum permissible, 40 amps continuous current of the | ||||||

trodes |

| 240 VAC output is 42 amps maximum. | |||||

Some recommended solid wires for MIG welding are: .035 | NOTE: Machines with code numbers of 11121 and | ||||||

(0.9mm), and .045 (1.1mm), | higher are equipped with GFCI duplex receptacles. If | ||||||

.045 (1.1mm) Blue Max MIG 308 LS. |

| a GFCI receptacle is “tripped”, it will not reset unless | |||||

For any electrodes, including those above, the procedure should | it is receiving nearly full voltage from the generator; for | ||||||

this reason, the engine must be running at high RPM | |||||||

be kept within the rating of the machine. |

| before resetting a GFCI. | |||||

|

| RANGER 305D |

|

|

| ||