Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

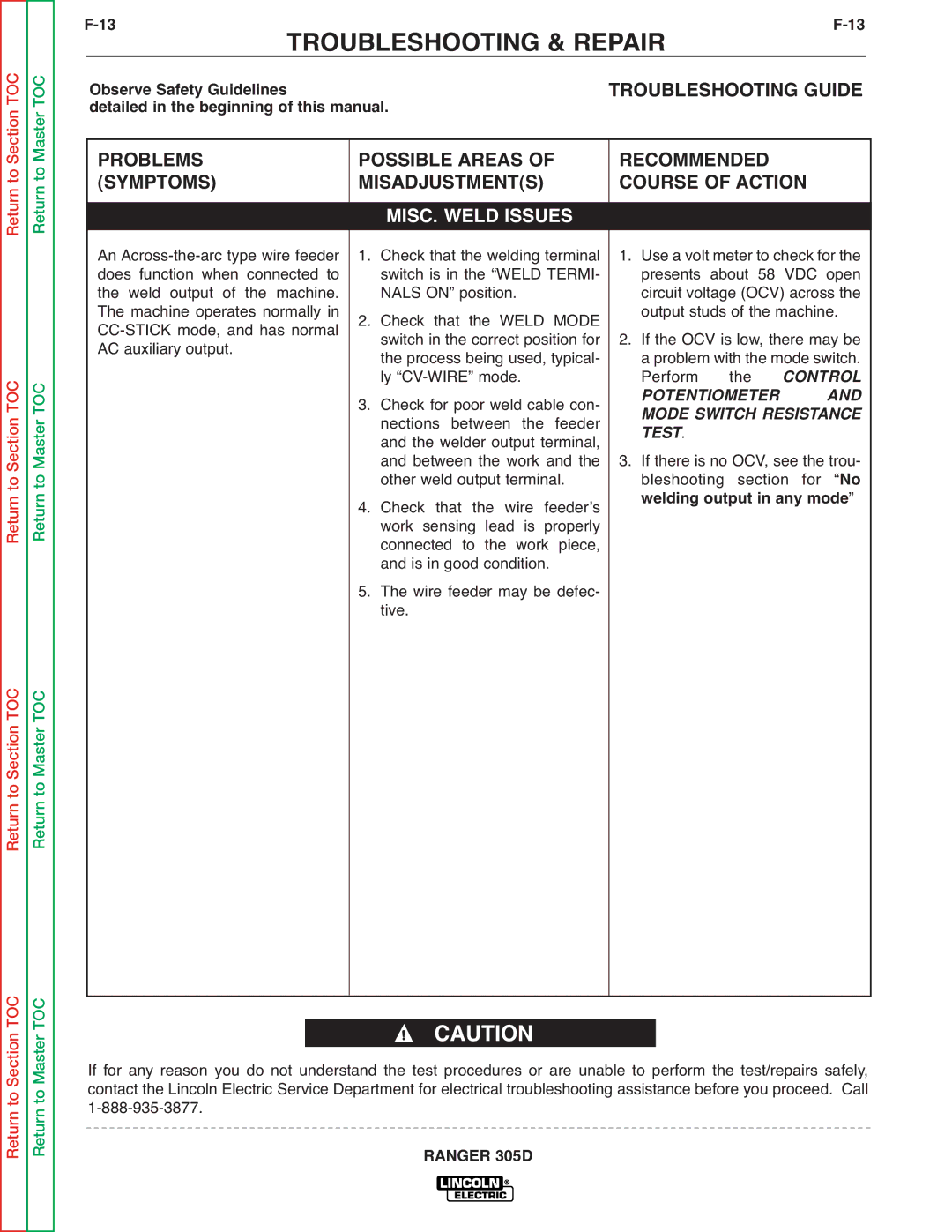

TROUBLESHOOTING & REPAIR |

|

| ||||||

| detailed in the beginning of this manual. | TROUBLESHOOTING GUIDE |

| |||||

| Observe Safety Guidelines |

|

|

|

|

|

| |

| PROBLEMS |

| POSSIBLE AREAS OF | RECOMMENDED |

|

| ||

| (SYMPTOMS) |

| MISADJUSTMENT(S) | COURSE OF ACTION |

| |||

|

|

| MISC. WELD ISSUES |

|

|

|

|

|

| An | 1. Check that the welding terminal | 1. Use a volt meter to check for the |

| ||||

| does function when connected to | switch is in the “WELD TERMI- |

| presents about 58 VDC open |

| |||

| the weld output of the machine. | NALS ON” position. |

| circuit voltage (OCV) across the |

| |||

| The machine operates normally in | 2. Check that the WELD MODE | 2. | output studs of the machine. |

| |||

| switch in the correct position for | If the OCV is low, there may be |

| |||||

| AC auxiliary output. |

| the process being used, typical- |

| a problem with the mode switch. |

| ||

|

|

| ly |

| Perform the | CONTROL |

| |

|

|

| 3. Check for poor weld cable con- |

| MODE SWITCH RESISTANCE |

| ||

|

|

| nections between the feeder |

| POTENTIOMETER | AND |

| |

|

|

|

| TEST | . |

|

| |

|

|

| and the welder output terminal, | 3. |

|

|

| |

|

|

| and between the work and the | If there is no OCV, see the trou- |

| |||

|

|

| other weld output terminal. |

| bleshooting section for “No |

| ||

|

|

| 4. Check that the wire feederʼs |

| welding output in any mode” |

| ||

|

|

| work sensing lead is properly |

|

|

|

|

|

|

|

| connected to the work piece, |

|

|

|

|

|

|

|

| and is in good condition. |

|

|

|

|

|

|

|

| 5. The wire feeder may be defec- |

|

|

|

|

|

|

|

| tive. |

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call