Return to Section TOC

Return to Section TOC

Section TOC

Return to Master TOC

Return to Master TOC

Master TOC

ACCESSORIES | ||||||

| CONNECTION OF THE | 5. | Place the “IDLER” switch in the “HIGH” position. | |||

| RANGER 305D USING K595 CONTROL |

| CAUTION |

| ||

| CABLE |

|

|

| ||

| (SEE FIGURE C.6.) |

| Any increase of the high idle engine RPM by changing | |||

| NOTE: If your | the governor setting or overriding the throttle linkage | ||||

| K404 input cable, refer to CONNECTIONS OF THE | will cause an increase in the AC auxiliary voltage. If | ||||

| this voltage goes over 140 volts, wire feeder control cir- | |||||

| this discussion, to connect your Ranger 305D for wire | cuit may be damaged. The engine governor setting is | ||||

| feed welding. |

| preset at the factory - do not adjust above RPM speci- | |||

1. | Shut the welder off. |

| fications listed in this manual. |

| ||

| ||||||

2. | Connect the electrode cable from the | 6. | Set the “VOLTMETER” switch to “+” or | |||

|

| “+” terminal of the welder. Connect the work cable |

| ing on the polarity chosen. |

| |

|

| to the |

| 7. | Set the “MODE” switch to |

|

| NOTE: Welding cable must be sized for current and |

| ||||

| duty cycle of application. |

| 8. | Set the “WELD TERMINALS” switch to “WELD |

| |

| NOTE: Figure C.5 shows the electrode connected for |

| TERMINALS REMOTELY CONTROLLED.” |

| ||

| positive polarity. To change polarity, shut the welder | 9. | Adjust wire feed speed and voltage at the | |||

| off and reverse the electrode and work cables at the | |||||

| output terminals. |

| 10. Adjust the “ARC” control to “0” initially and adjust | |||

3. | Connect the |

| to suit. |

| ||

| 4. Connect the |

|

|

| ||

|

| the Ranger 305D. |

|

|

|

|

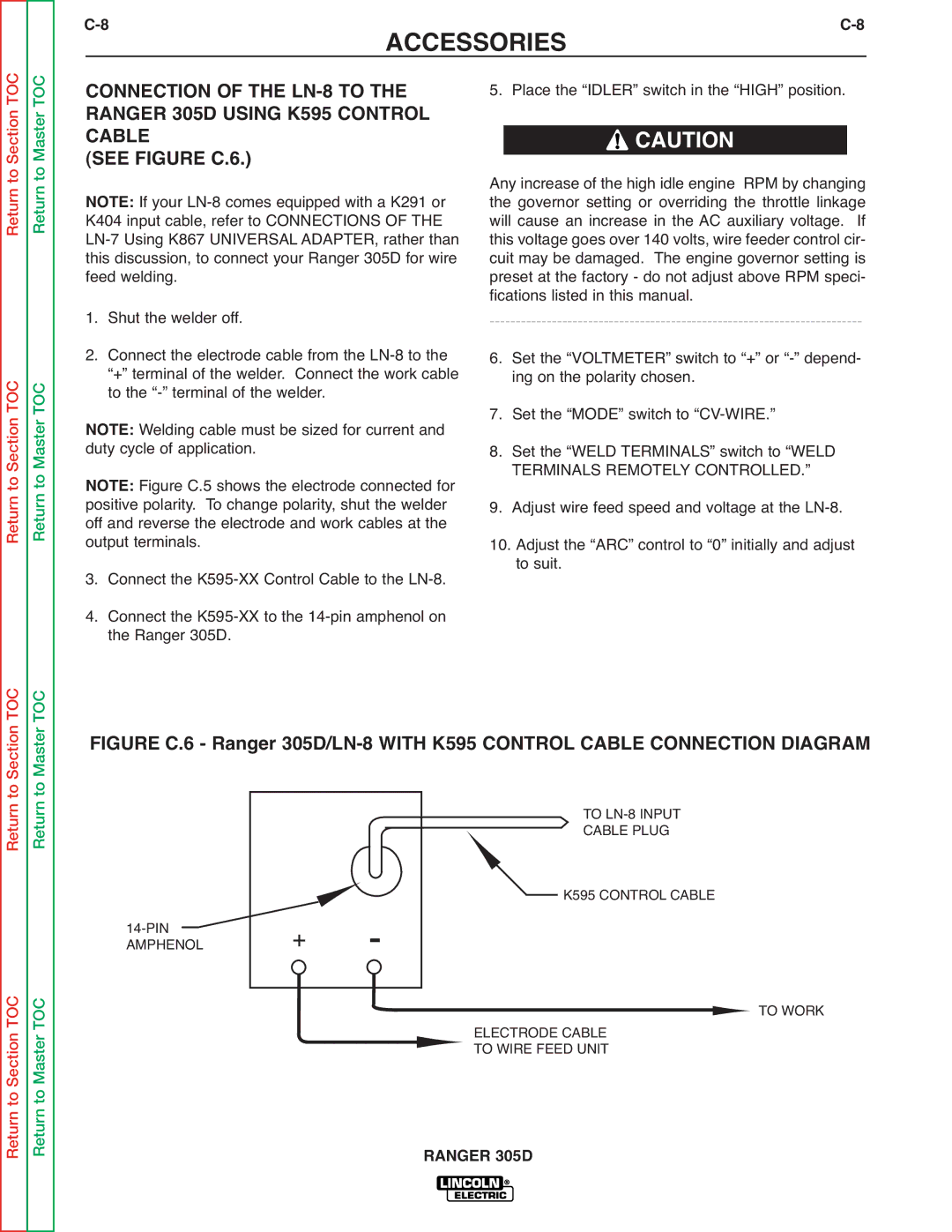

FIGURE C.6 - Ranger 305D/LN-8 WITH K595 CONTROL CABLE CONNECTION DIAGRAM

TO

CABLE PLUG

+ | - | K595 CONTROL CABLE |

|

|

|

| |

|

| ELECTRODE CABLE | TO WORK |

|

| TO WIRE FEED UNIT |

|