Section TOC

Master TOC

THEORY OF OPERATION | |||

|

| FIGURE E.5 – WELD POWER & CONTROL |

|

Return to

Return to Section TOC

Return to

Return to Master TOC

12V.

BATTERY

GLOW

PLUG

BUTTON

RUN

STOP

SWITCH

|

|

| SHUNT | + |

|

|

|

| |

POWER | IGBTs | CHOKE |

| - |

MODULE |

|

|

ENGINE |

|

| CHARGING |

|

PROTECTION |

|

|

| |

LIGHT |

|

| SYSTEM LIGHT |

|

|

|

| (CODE 10926 ONLY) |

|

ENGINE | ENGINE | GLOW | ENGINE |

|

PROTECTION | WELD | |||

CIRCUIT | SENSORS | PLUGS | ALTERNATOR | |

|

|

|

| WINDING |

PUMP | ENGINE |

|

| ROTOR |

|

|

|

| |||

FUEL |

|

|

|

|

|

|

|

|

| ||

FUEL |

|

|

|

|

|

|

|

|

|

|

|

SOLENIOD |

|

|

|

|

|

|

|

|

|

|

|

HOLD COIL |

|

|

|

|

|

|

|

|

|

|

|

PULL COIL |

|

|

|

| STATOR |

|

|

|

|

|

|

START | STARTER |

| EXCITER |

| 42 VAC | WELD CONTROL | AMP | ||||

IDLE | 120/240 VAC | DISPLAY | |||||||||

BUTTON | WINDING AUX.WINDING | WINDING |

| P.C. BOARD | VOLT | ||||||

| SOLENOID |

| 240 | CURRENT |

|

|

| DISPLAY | |||

| PULL | HOLD |

| SENSOR | 14 | 6 |

|

|

| ||

| COIL | COIL | FLASHING | VAC | 120 |

| PIN |

|

|

| |

| PULL COIL |

| RECEPTACLES vac |

| AMPHENALS | PIN |

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| |

| PC BOARD |

|

|

|

|

|

|

|

|

| IDLE |

|

|

|

|

|

|

|

| OUTPUT | MODE | WELDING | |

|

|

|

|

|

|

|

| SWITCH | |||

|

|

|

|

|

|

|

| CONTROL | SWITCH TERMINAL |

| |

|

|

|

|

|

|

|

| ARC |

| SWITCH |

|

|

|

|

|

|

|

|

| CONTROL |

|

| |

Return to Section TOC

to Section TOC

Return to Master TOC

to Master TOC

Weld Power and Control

Weld Power:

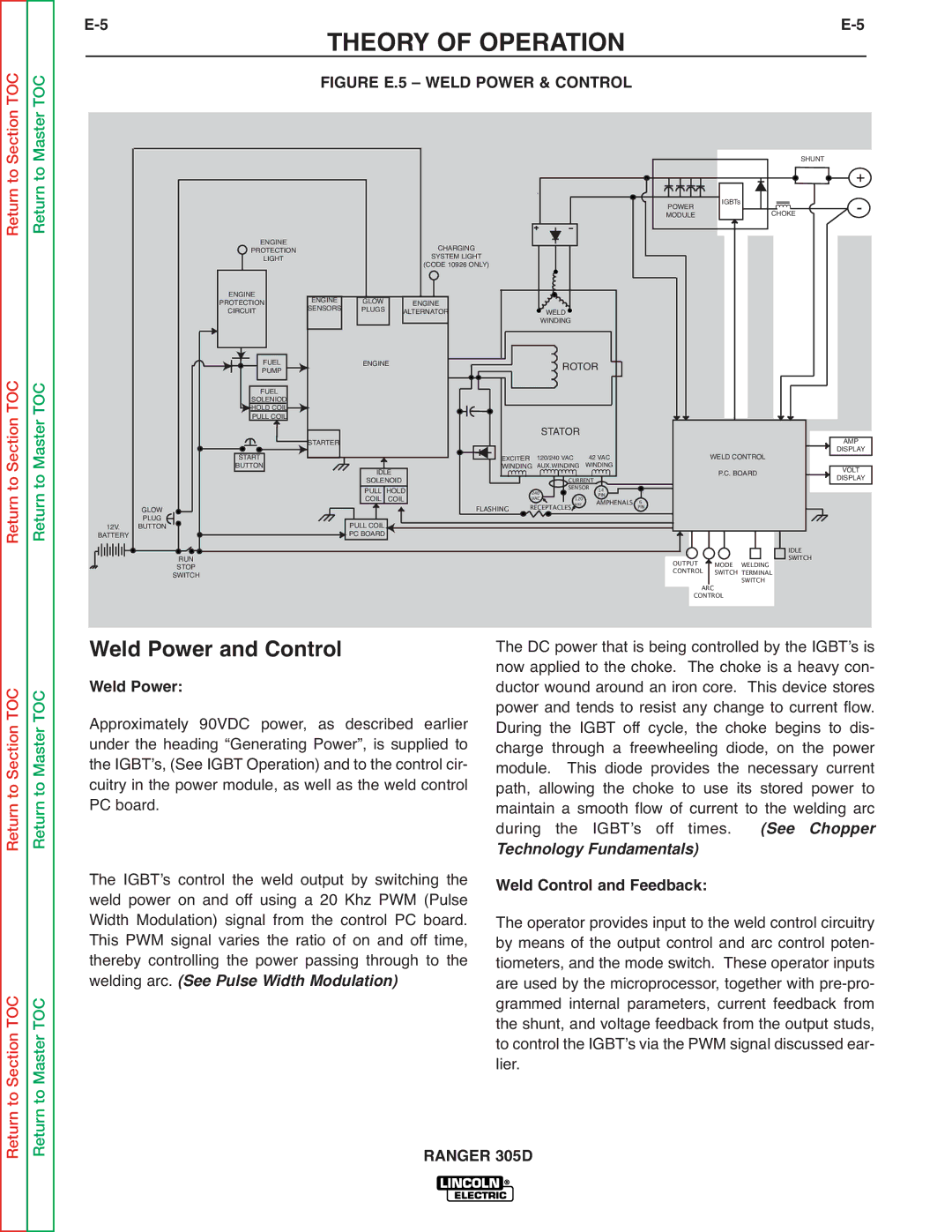

Approximately 90VDC power, as described earlier under the heading “Generating Power”, is supplied to the IGBTʼs, (See IGBT Operation) and to the control cir- cuitry in the power module, as well as the weld control PC board.

The IGBTʼs control the weld output by switching the weld power on and off using a 20 Khz PWM (Pulse Width Modulation) signal from the control PC board. This PWM signal varies the ratio of on and off time, thereby controlling the power passing through to the welding arc. (See Pulse Width Modulation)

The DC power that is being controlled by the IGBTʼs is now applied to the choke. The choke is a heavy con- ductor wound around an iron core. This device stores power and tends to resist any change to current flow. During the IGBT off cycle, the choke begins to dis- charge through a freewheeling diode, on the power module. This diode provides the necessary current path, allowing the choke to use its stored power to maintain a smooth flow of current to the welding arc during the IGBTʼs off times. (See Chopper

Technology Fundamentals)

Weld Control and Feedback:

The operator provides input to the weld control circuitry by means of the output control and arc control poten- tiometers, and the mode switch. These operator inputs are used by the microprocessor, together with

Return

Return