Section TOC

Master TOC

THEORY OF OPERATION | |||

|

| FIGURE E.4 – GENERATING POWER & OUTPUT |

|

Return to

Return to Section TOC

Return to

Return to Master TOC

12V.

BATTERY

GLOW

PLUG

BUTTON

RUN

STOP

SWITCH

|

|

| SHUNT | + |

|

|

|

| |

POWER | IGBTs | CHOKE |

| - |

MODULE |

|

|

ENGINE |

|

| CHARGING |

|

PROTECTION |

|

|

| |

LIGHT |

|

| SYSTEM LIGHT |

|

|

|

| (CODE 10926 ONLY) |

|

ENGINE | ENGINE | GLOW | ENGINE |

|

PROTECTION | WELD | |||

CIRCUIT | SENSORS | PLUGS | ALTERNATOR | |

|

|

|

| WINDING |

PUMP | ENGINE |

|

| ROTOR |

|

|

|

| |||

FUEL |

|

|

|

|

|

|

|

|

| ||

FUEL |

|

|

|

|

|

|

|

|

|

|

|

SOLENIOD |

|

|

|

|

|

|

|

|

|

|

|

HOLD COIL |

|

|

|

|

|

|

|

|

|

|

|

PULL COIL |

|

|

|

| STATOR |

|

|

|

|

|

|

START | STARTER |

| EXCITER |

| 42 VAC | WELD CONTROL | AMP | ||||

IDLE | 120/240 VAC | DISPLAY | |||||||||

BUTTON | WINDING AUX.WINDING | WINDING |

| P.C. BOARD | VOLT | ||||||

| SOLENOID |

| 240 | CURRENT |

|

|

| DISPLAY | |||

| PULL | HOLD |

| SENSOR | 14 | 6 |

|

|

| ||

| COIL | COIL | FLASHING | VAC | 120 |

| PIN |

|

|

| |

| PULL COIL |

| RECEPTACLES vac |

| AMPHENALS | PIN |

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| |

| PC BOARD |

|

|

|

|

|

|

|

|

| IDLE |

|

|

|

|

|

|

|

| OUTPUT | MODE | WELDING | |

|

|

|

|

|

|

|

| SWITCH | |||

|

|

|

|

|

|

|

| CONTROL | SWITCH TERMINAL |

| |

|

|

|

|

|

|

|

| ARC |

| SWITCH |

|

|

|

|

|

|

|

|

| CONTROL |

|

| |

Return to Section TOC

to Section TOC

Return to Master TOC

to Master TOC

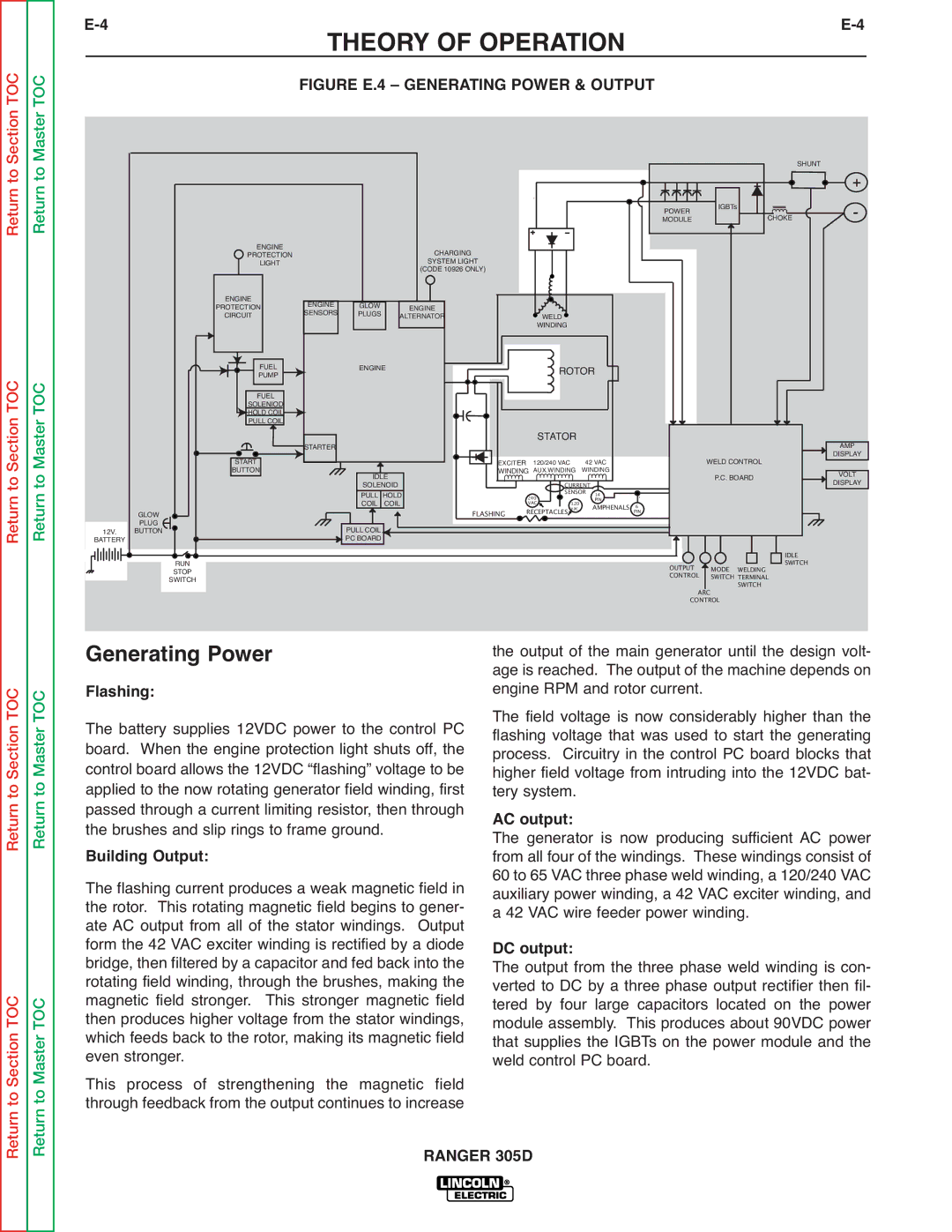

Generating Power

Flashing:

The battery supplies 12VDC power to the control PC board. When the engine protection light shuts off, the control board allows the 12VDC “flashing” voltage to be applied to the now rotating generator field winding, first passed through a current limiting resistor, then through the brushes and slip rings to frame ground.

Building Output:

The flashing current produces a weak magnetic field in the rotor. This rotating magnetic field begins to gener- ate AC output from all of the stator windings. Output form the 42 VAC exciter winding is rectified by a diode bridge, then filtered by a capacitor and fed back into the rotating field winding, through the brushes, making the magnetic field stronger. This stronger magnetic field then produces higher voltage from the stator windings, which feeds back to the rotor, making its magnetic field even stronger.

This process of strengthening the magnetic field through feedback from the output continues to increase

the output of the main generator until the design volt- age is reached. The output of the machine depends on engine RPM and rotor current.

The field voltage is now considerably higher than the flashing voltage that was used to start the generating process. Circuitry in the control PC board blocks that higher field voltage from intruding into the 12VDC bat- tery system.

AC output:

The generator is now producing sufficient AC power from all four of the windings. These windings consist of 60 to 65 VAC three phase weld winding, a 120/240 VAC auxiliary power winding, a 42 VAC exciter winding, and a 42 VAC wire feeder power winding.

DC output:

The output from the three phase weld winding is con- verted to DC by a three phase output rectifier then fil- tered by four large capacitors located on the power module assembly. This produces about 90VDC power that supplies the IGBTs on the power module and the weld control PC board.

Return

Return