Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

|

|

|

| ||

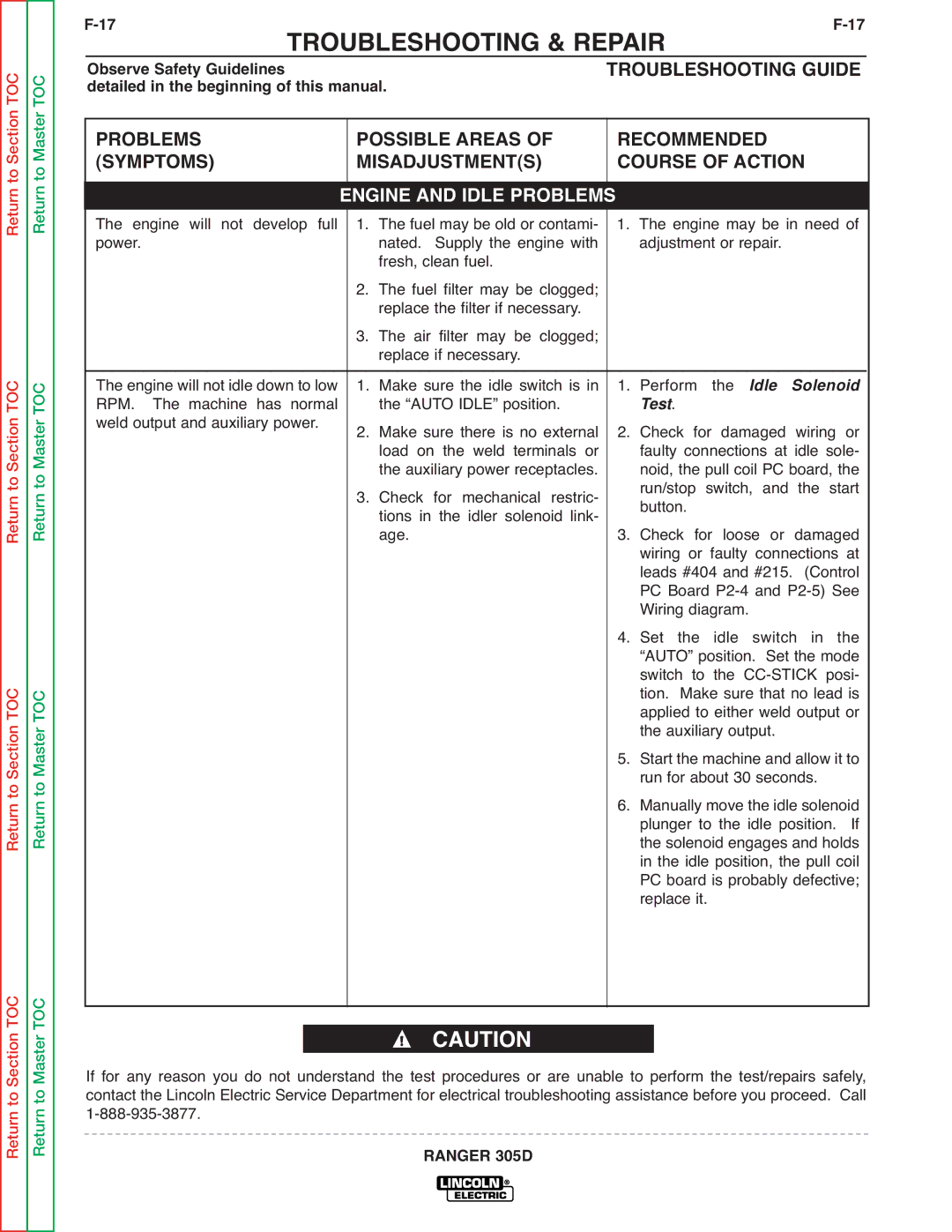

Observe Safety GuidelinesTROUBLESHOOTING & REPAIR |

| ||||

detailed in the beginning of this manual. | TROUBLESHOOTING GUIDE | ||||

PROBLEMS | POSSIBLE AREAS OF |

| RECOMMENDED |

| |

(SYMPTOMS) | MISADJUSTMENT(S) |

| COURSE OF ACTION |

| |

| ENGINE AND IDLE PROBLEMS |

|

| ||

The engine will not develop full | 1. | The fuel may be old or contami- |

| 1. The engine may be in need of | |

power. |

| nated. Supply the engine with |

| adjustment or repair. |

|

|

| fresh, clean fuel. |

|

|

|

| 2. The fuel filter may be clogged; |

|

|

| |

|

| replace the filter if necessary. |

|

|

|

| 3. The air filter may be clogged; |

|

|

| |

|

| replace if necessary. |

|

|

|

The engine will not idle down to low | 1. | Make sure the idle switch is in |

| 1. Perform the Idle Solenoid | |

RPM. The machine has normal | 2. | the “AUTO IDLE” position. |

| Test. |

|

weld output and auxiliary power. | Make sure there is no external |

| 2. Check for damaged wiring or | ||

|

| load on the weld terminals or |

| faulty connections at idle sole- | |

|

| the auxiliary power receptacles. |

| noid, the pull coil PC board, the | |

| 3. Check for mechanical restric- |

| run/stop switch, and the start | ||

|

| tions in the idler solenoid link- |

| button. |

|

|

| age. |

| 3. Check for loose or damaged | |

|

|

|

| wiring or faulty connections at | |

|

|

|

| leads #404 and #215. (Control | |

|

|

|

| PC Board | |

|

|

|

| Wiring diagram. |

|

|

|

|

| 4. Set the idle switch in the | |

|

|

|

| “AUTO” position. Set the mode | |

|

|

|

| switch to the | |

|

|

|

| tion. Make sure that no lead is | |

|

|

|

| applied to either weld output or | |

|

|

|

| the auxiliary output. |

|

|

|

|

| 5. Start the machine and allow it to | |

|

|

|

| run for about 30 seconds. |

|

|

|

|

| 6. Manually move the idle solenoid | |

|

|

|

| plunger to the idle position. If | |

|

|

|

| the solenoid engages and holds | |

|

|

|

| in the idle position, the pull coil | |

|

|

|

| PC board is probably defective; | |

|

|

|

| replace it. |

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call