Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

|

|

|

|

|

|

|

|

|

|

| ||||

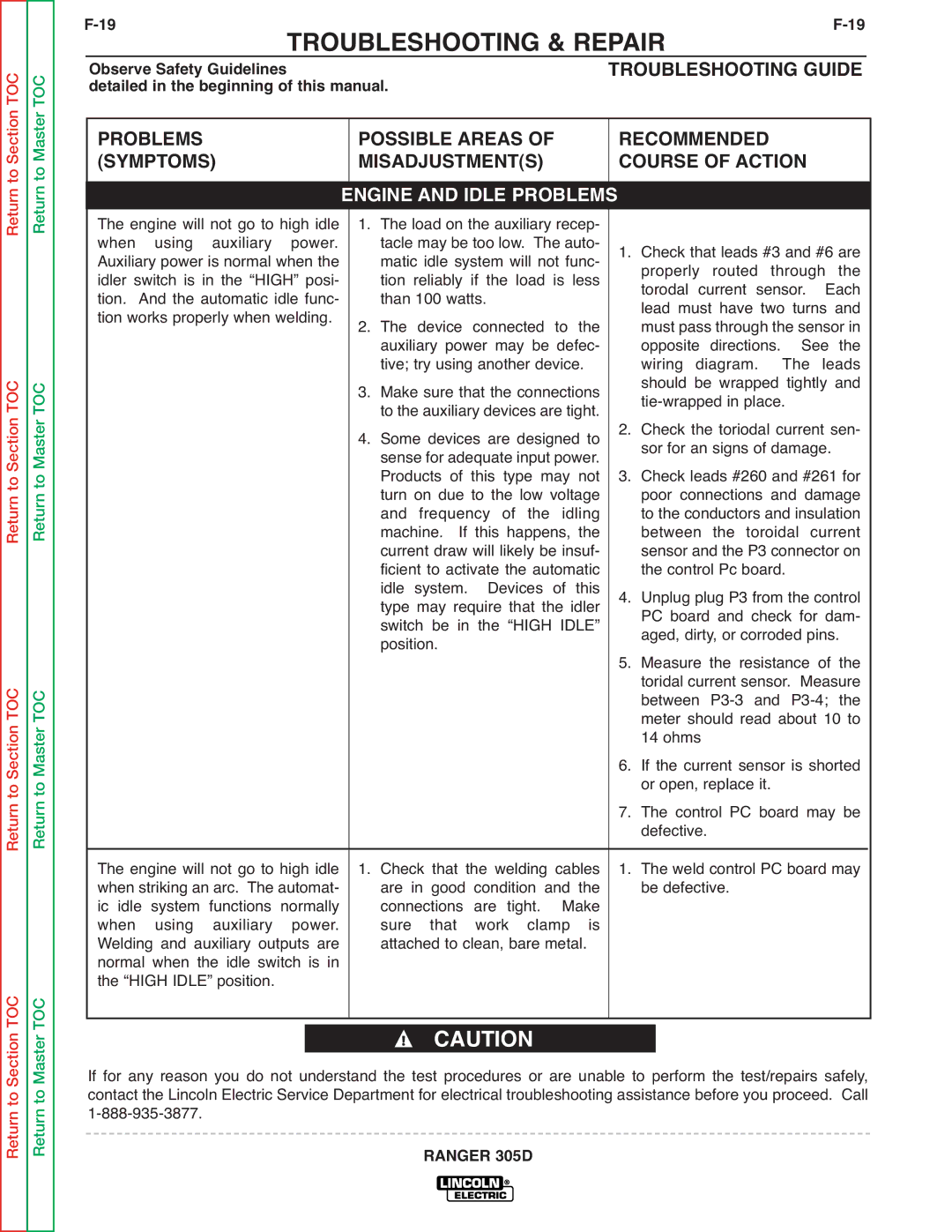

| Observe Safety GuidelinesTROUBLESHOOTING & REPAIR |

|

|

| ||||||||||

| detailed in the beginning of this manual. |

|

| TROUBLESHOOTING GUIDE | ||||||||||

| PROBLEMS |

|

| POSSIBLE AREAS OF |

| RECOMMENDED |

|

|

| |||||

| (SYMPTOMS) |

| MISADJUSTMENT(S) |

|

| COURSE OF ACTION |

|

| ||||||

|

|

|

|

| ENGINE AND IDLE PROBLEMS |

|

|

|

|

| ||||

| The engine will not go to high idle | 1. | The load on the auxiliary recep- |

| 1. | Check that leads #3 and #6 are | ||||||||

| when | using | auxiliary | power. |

| tacle may be too low. The auto- |

| |||||||

| Auxiliary power is normal when the |

| matic idle system will not func- |

|

| properly routed through the | ||||||||

| idler switch is in the “HIGH” posi- |

| tion reliably if the load is less |

|

| torodal current sensor. | Each | |||||||

| tion. | And the automatic idle func- |

| than 100 watts. | to the |

|

| lead must have two turns and | ||||||

| tion works properly when welding. | 2. The device | connected |

|

| must pass through the sensor in | ||||||||

|

|

|

|

|

| auxiliary power may be defec- |

|

| opposite directions. | See the | ||||

|

|

|

|

| 3. | tive; try using another device. |

|

| wiring diagram. | The | leads | |||

|

|

|

|

| Make sure that the connections |

|

| should be wrapped tightly and | ||||||

|

|

|

|

| 4. | to the auxiliary devices are tight. |

| 2. |

|

| ||||

|

|

|

|

| Some devices are designed to |

| Check the toriodal current sen- | |||||||

|

|

|

|

|

| sense for adequate input power. |

| 3. | sor for an signs of damage. | |||||

|

|

|

|

|

| Products of this type may not |

| Check leads #260 and #261 for | ||||||

|

|

|

|

|

| turn on due to the low voltage |

|

| poor connections and damage | |||||

|

|

|

|

|

| and frequency of the idling |

|

| to the conductors and insulation | |||||

|

|

|

|

|

| machine. If this happens, the |

|

| between the toroidal | current | ||||

|

|

|

|

|

| current draw will likely be insuf- |

|

| sensor and the P3 connector on | |||||

|

|

|

|

|

| ficient to activate the automatic |

| 4. | the control Pc board. |

|

| |||

|

|

|

|

|

| idle system. | Devices | of this |

| Unplug plug P3 from the control | ||||

|

|

|

|

|

| type may require that the idler |

|

| PC board and check for dam- | |||||

|

|

|

|

|

| switch be in the “HIGH IDLE” |

|

| aged, dirty, or corroded pins. | |||||

|

|

|

|

|

| position. |

|

|

| 5. Measure the resistance | of the | |||

|

|

|

|

|

|

|

|

|

|

| toridal current sensor. Measure | |||

|

|

|

|

|

|

|

|

|

|

| between | |||

|

|

|

|

|

|

|

|

|

|

| meter should read about 10 to | |||

|

|

|

|

|

|

|

|

|

|

| 14 ohms |

|

|

|

|

|

|

|

|

|

|

|

|

| 6. If the current sensor is shorted | ||||

|

|

|

|

|

|

|

|

|

|

| or open, replace it. |

|

|

|

|

|

|

|

|

|

|

|

|

| 7. The control PC board may be | ||||

|

|

|

|

|

|

|

|

|

|

| defective. |

|

|

|

| The engine will not go to high idle | 1. Check that the welding cables |

| 1. | The weld control PC board may |

| ||||||||

| when striking an arc. The automat- |

| are in good condition and the |

|

| be defective. |

|

|

| |||||

| ic idle system functions normally |

| connections | are tight. | Make |

|

|

|

|

|

| |||

| when | using | auxiliary | power. |

| sure that work clamp is |

|

|

|

|

|

| ||

| Welding and auxiliary outputs are |

| attached to clean, bare metal. |

|

|

|

|

|

| |||||

| normal when the idle switch is in |

|

|

|

|

|

|

|

|

|

| |||

| the “HIGH IDLE” position. |

|

|

|

|

|

|

|

|

|

|

| ||

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call