Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

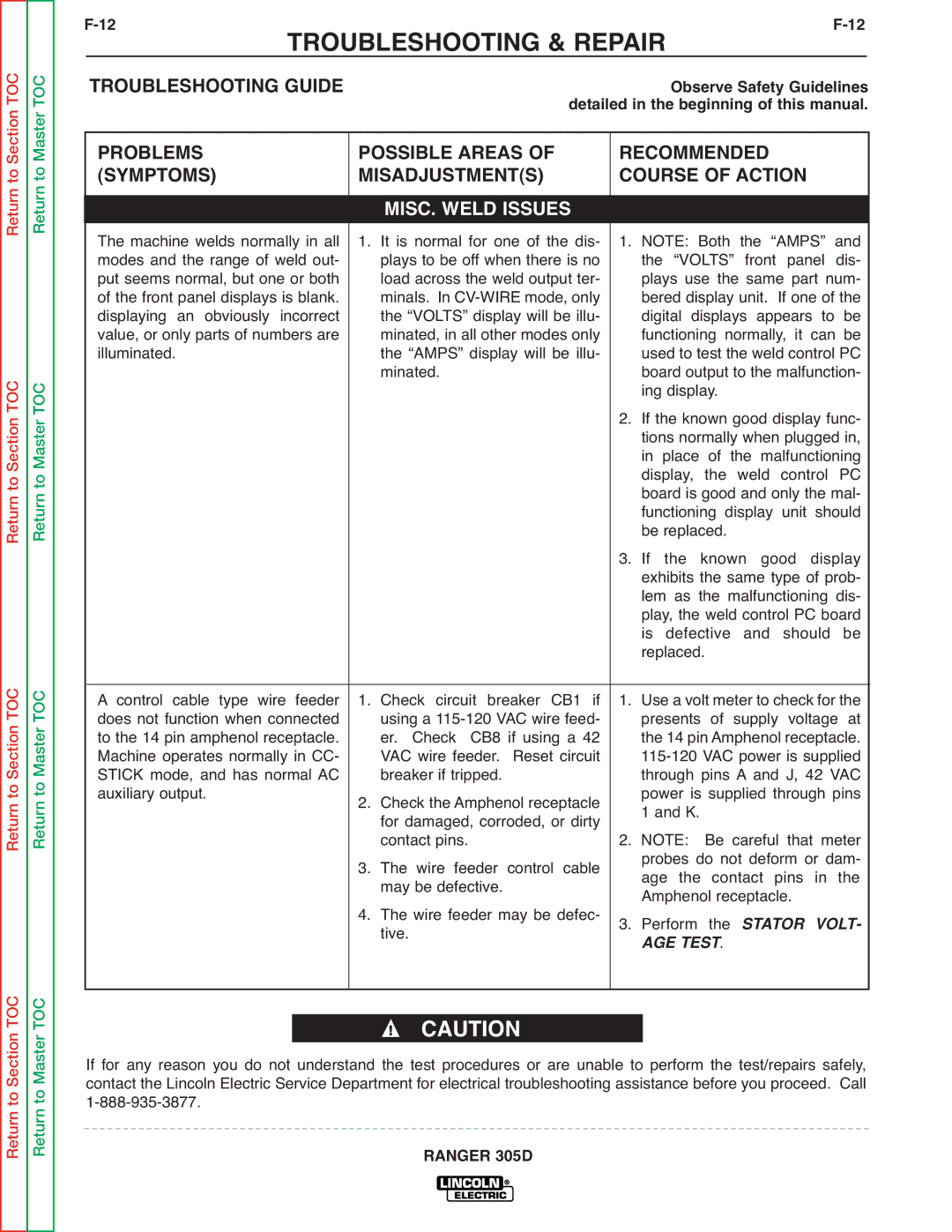

TROUBLESHOOTING & REPAIR | |||||||

| TROUBLESHOOTING GUIDE |

|

| Observe Safety Guidelines |

| ||

|

|

|

| detailed in the beginning of this manual. | |||

| PROBLEMS |

| POSSIBLE AREAS OF | RECOMMENDED |

|

| |

| (SYMPTOMS) |

| MISADJUSTMENT(S) | COURSE OF ACTION |

|

| |

|

|

|

| MISC. WELD ISSUES |

|

|

|

| The machine welds normally in all | 1. | It is normal for one of the dis- | 1. NOTE: Both the “AMPS” and | |||

| modes and the range of weld out- |

| plays to be off when there is no | the “VOLTS” front panel dis- | |||

| put seems normal, but one or both |

| load across the weld output ter- | plays use the same part num- | |||

| of the front panel displays is blank. |

| minals. In | bered display unit. If one of the | |||

| displaying an obviously | incorrect |

| the “VOLTS” display will be illu- | digital displays appears to be | ||

| value, or only parts of numbers are |

| minated, in all other modes only | functioning normally, it can be | |||

| illuminated. |

|

| the “AMPS” display will be illu- | used to test the weld control PC | ||

|

|

|

| minated. | board output to the malfunction- | ||

|

|

|

|

| ing display. |

|

|

|

|

|

|

| 2. If the known good display func- | ||

|

|

|

|

| tions normally when plugged in, | ||

|

|

|

|

| in place of the malfunctioning | ||

|

|

|

|

| display, the weld control PC | ||

|

|

|

|

| board is good and only the mal- | ||

|

|

|

|

| functioning display unit | should | |

|

|

|

|

| be replaced. |

|

|

|

|

|

|

| 3. If the known good display | ||

|

|

|

|

| exhibits the same type of prob- | ||

|

|

|

|

| lem as the malfunctioning dis- | ||

|

|

|

|

| play, the weld control PC board | ||

|

|

|

|

| is defective and should be | ||

|

|

|

|

| replaced. |

|

|

| A control cable type wire feeder | 1. Check circuit breaker CB1 if | 1. Use a volt meter to check for the | ||||

| does not function when connected |

| using a | presents of supply voltage at | |||

| to the 14 pin amphenol receptacle. |

| er. Check CB8 if using a 42 | the 14 pin Amphenol receptacle. | |||

| Machine operates normally in CC- |

| VAC wire feeder. Reset circuit | ||||

| STICK mode, and has normal AC | 2. | breaker if tripped. | through pins A and J, 42 VAC | |||

| auxiliary output. |

| Check the Amphenol receptacle | power is supplied through pins | |||

|

|

|

| for damaged, corroded, or dirty | 1 and K. |

|

|

|

|

|

| contact pins. | 2. NOTE: Be careful that meter | ||

|

|

| 3. The wire feeder control cable | probes do not deform or dam- | |||

|

|

| age the contact pins in the | ||||

|

|

| 4. | may be defective. | Amphenol receptacle. |

|

|

|

|

| The wire feeder may be defec- | 3. Perform the STATOR VOLT- | |||

|

|

|

| tive. | AGE TEST. |

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call