Combitherm

Intr Oduction Contro L Panel Identification

COM BI Nati on OVE N/STEAMER

Fish & Seafood

OM BI NAT ION Oven /STEAMER

Combination OVEN/S Teamer

Moisture Vent KEY

ST AN Dard Deluxe Contr OL Pane L BAS IC Function

Ke y This Indi ca tor

This Indi ca tor

SIG NAL Tone

ET- UP PRO CE DU RE S SET UP Menu

SET UP Adjustment Choices

T-UP ROC ED UR ES

Volume

Time

Date

Defaul T/ME MO Setti NG

Press the C HEF Function KEY to Confir M the Memo Setting

Comb Ithe RM FA Ctory SET DE Fault S Ettings

Lang UAG E

TE Mperature D Ispla Y

Netw ORK ADD Ress

Impor TAN T SA Fety Precaut Ions

To Change T HE Settings Show

Stea M Mode

Steam

Steam M ODE CH EF Oper Ating Tips

To C Hange the SET Tings Shown

COM Bination M ODE

Combination Mode Chef Opera Ting Tips

To C Hange TH E Settings Shown

CON VE Ction Mode

Convect ION Mode Chef Opera Ting Tips

To C Hange the Settings Show

Press TH E Start KEY to Cook AT the Setting S Shown

Pres S the Star T KEY to Begi N the Retherm Mode

RE Ther M M ODE

Ban quet r ethe rmali zati on i s desi gned for high

Retherm MO DE Chef Operating Tips

Press T HE Core Temp KEY

COR E TEM Peratur E Probe Mode

Pres S the Star T KEY to Begi N the Cook ING Mode

Press T HE Chef Function KEY to CON Firm the Settin G

Oven W ILL Begin the DELTA-T Convec Tion Cook ING Mode

DELTA-T COR E TEM Perature CO Okin G

Press the Chef FUN Ction KEY

Auxiliar Y Functions Chef Functi on KEY

REH EAT ING

Gold BRO

Auxili ARY Functions Chef Function KEY

Press T HE CHE F Func Tion KE Y to CON Firm the Settin G

Pres S the Star T KEY

Cool Do WN FE AT UR E

Auxili ARY Functions Chef Functi on KEY

Pres S the CHE F FUN Ction KEY

Pres S the CHE F FUN Ction KEY to Confir M the S Etting

RED Uced FAN SP EED

Auxil Iary Functions Chef Function KEY

Press T HE CHE F Function KEY

Press T HE CHE F Function KEY to CON Firm the Sett ING

EY UNL OCK

KEY Lock

Steam Inje Ction

Auxili ARY Functions Chef Funct ION KEY

Load W OOD Chips

Auxiliary Functions General Smoker Operation

SM OK ING Functio N

PRE SS the TEM PER Atur E KE Y

SMO KE R FEA Ture

PRE SS the Time KEY

PRE SS the CHE F FUN Ction K EY

ENE RGY PRO Tectio

Energ LO CK

Advance F Eatures Moisture Vent KEY

Press the TE MPE Rature K EY

Advance F Eatur ES Quic K Progr Amming

Adva NCE F Eatur ES

Select and Press the Required Cooking Mode

Start TIM E Preselect

Adjus Tment K NOB

OM BIT Herm Progr Ammin G Symbo LS

Press the Progra M in Stall /EDIT KEY

To Cancel the Reco Rding Funct ION

Savi N G a Reco Rded Cooking PR Ocedur

Select AN D PRE SS the F Irst RE Quire D CO Oking M ODE

Pres S the P Rogram in STALL/EDIT KEY

Copy Prog RAM ME D PR Ocedure

ST ART a PRO Gramm ED PR Ocedure

DE LE TE a Prog Ramm ED PR Oced URE

Press the P Rogramme D M ENU KEY

Pres S the P Rogram in Stall and Edit KEY

ED IT a Prog Rammed PRO Cedure

Press T HE Programmed ME NU KEY

Pres S the P Rogram in Stall KEY

Inse RT a PRO Gramm ED PR Ocedure S T EP

PR E SS TH E C HEF FU NC Tion KEY

Pres S the C HEF Func Tion KEY T O CON Firm T HE SE Lection

Appe ND a Program MED PRO Cedur E ST EP

Press the Progr AM Insta LL KEY

DE Lete a Prog RAM M ED ST EP

PRE S S TH E Chef FU NC Tion KEY

Press the Chef FUN Ction KEY to Confir S Electi on

Press AN a Ssigne D Rapid T Ouch KEY

To Assi GN a Proce DU RE to Rogra M RAPID-TO U CH KEY

To OP Erate a Proce Dure on RAP ID-T OU CH KEY

Mai nta ins ov en i n a s tand- by m ode

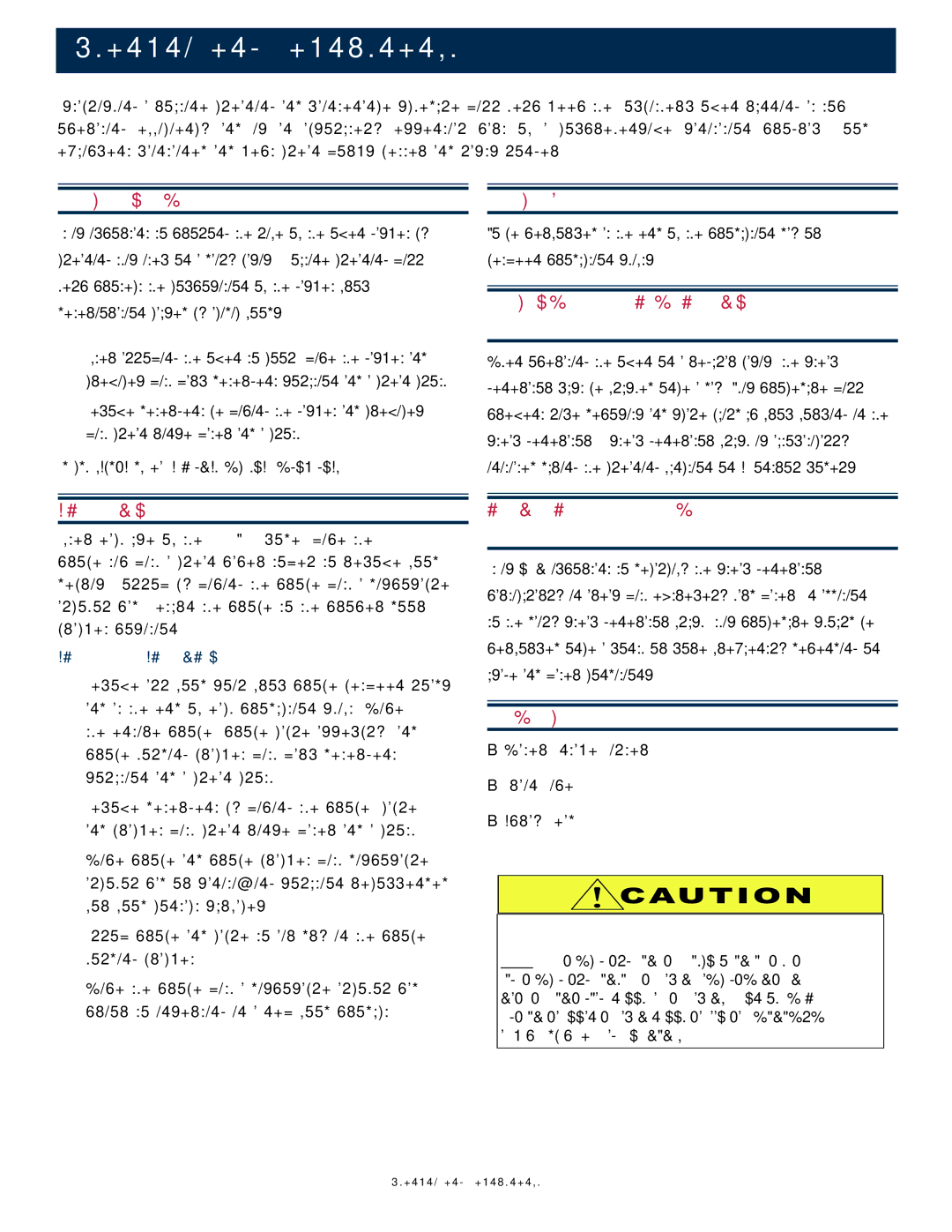

CON TRO L PA NEL Identification

Used to se t the requi red i nte rnal pro duct temperature

To be press ed to d ispla y interi or o ven temperature

To the r Equired cooki Ng mode

To the c Onvection mode Rotate

PRE Heati

Core TE Mperature

MOK ING

OLD- N- Brow N

Load Wood Chips

Wood Chips

CON Trol MO Dels

Pr ess th e Down � arrow Ke ys

PRE HE ATI NG

Press the Chef Funct ION KEY

Pre ss and S et

Timer Press a nd S et TIM ER

20 to 25 minutes

Pre ss and S et Core

Pre ss and S et TIM ER

50 to 60 mi nutes

To 37 5F 171 to 191 C

BRE AD DOU GH

20 to 25 m inutes

Sh elves

20 to 40 mi nutes

12 to 15 m inutes

15 to 20 mi nutes

Timer Pre ss and S et TIM ER

Min ute s

Timer Pre ss and S et Timer

EMP

Pre ss and S et TIM ER

Pre ss and S et Core

Thawed

From Frozen

Fresh

Core EMP

Low Temper ature Stea m

Bread d ough v ari ous

90 to 100F 32 to 38 C

15 to 45 mi nutes

Oz 8 5 gm

Timer Pre ss and S et Timer

Min ute s Oz 8 5 gm

10 to 12 m inutes

10 GN 2 /1 Half-size s heet pa ns 1 8 x 13 x

Frost rolls when cool if desired

Cinnamon roll dough 5 oz 142 gm per roll

Dinn er roll dough To 4 o z 85 to 113 gm per r oll

10 to 15 mi nutes

Par- baked r oll s To 4 o z 85 to 113 gm per r oll

Place p ar-b aked r olls o n l ined p ans

N/2/1

Ha lf- size s heet p ans 5 GN 1

Shee t Cak e

Sheet p ans o r c ake m olds Pan l iners

FR OM F Roze N

Pres s and Se t TIM ER

165F 74C

Min ute s

If REF Rige Rated

If FR Ozen

Selected e ntrées sh ould re main

275 F 135 C

Frozen un til r eady t o r eheat . D o n ot

Remove e ntrée f rom th e or iginal

Froze N

Lobster Tails

Whole L Obster

Whole

Tail

B 5 k g Ha lf- size s heet p ans 6 GN 1

Ora nge r ough y fi llets To 6 o z 113 to 170 gm ea ch

Min ute s 150 F 66C

B 13 k g

Core Temp

TIM ER

Pre ss Set

Not T O EXC EED

Press and Set Timer

COR E Temp

Pr es s an d Set

Pres s an d Se t Core TE MP

Timer Pres s and Se t TIM ER

Min ute s 150 F 66C

Pre ss and Set COR E Temp

Press and Se t Time R

Timer Press and Set Timer

By Time Co mbi nati on By Core TEM P Del ta-T

Beef rounds, top o r bottom 18 lb 8 k g e ach

250 F 121 C

15F

Min ute s 190 F 88C

Beef Shor t Ribs To 3 lb 1 to 1,3 kg

Spray p ans wi th v egetable r elease

Spray i f d esired

275F 135C Minutes

Beef Ribs, 2-3 lb 1 to 1,3 kg

Minutes 190F 88C

Spray if desired

Min ute s 185 F 85C

Timer Press and S et Time R

Skin Side D OWN

Pr es s and Se t Core TE MP

FRO ZEN PIE CES

Thawed Pieces

Thawed H Alves

Froz EN HAL VES

If Thawed

350F 177C Minutes

Product Chicken, Whole 2-1/4 to 2-3/4 lb 1 to 1,2 kg each

Place chicken on sprayed, grid-lined

Sheet pans or on roasting racks. If

Ha lf- size s heet p ans

Timer

GN 1

For Rehe Ating

To 19 0F 10F To 8 8C To 6 C

Timer Pres s and S et TIM ER

Pres s An d Se t

150 to 160 F To 15 F 66 to 71C To 8C

Pre ss and Set Timer

Min utes per lb 165F Minute s per kg 74 C

If Froze N

Timer Press and Set Time R

If Thawe D

Pre ss and Set Core

Pre ss and Set

Alto -Shaam Combitherm Grill Grate Shelf Item SH-26731

460 F 238C

Season individual items as desired . Place on grill grate

Grill Grate Shelves

Core TEM P

Press and Set TIM ER

Pr es s and Set

Pres s Set TIM ER

150 to 160F 10 to 20F 66 to 71 C To 11C

Timer Pre ss and Set Timer

Pre ss and Set

Time R Press and Set Time R

From RAW

165F 74C

Minut es

180

Combin ati on mode 250F 121C Stea m mode 160F 71C

Pans or full-size pans

Full- size sheet pans or GN 2/1

Com bina tio n

Pork ribs 4 dow n

375F 19 1C

Min utes 165 F 74C

Boned Tied

CEN TER CUT

R K S H O U L D E R

Pre ss and Set Core

Press and Set Time R

Stea m 212F 100 C Low Temp eratur e Steam 160F 71 C

175 F 79C

Pre ss Set

150F 66C

Low Temper ature Stea m

150 to 160F To 15F 66 to 71 C To 8C

FRO M RAW

Precooked

Vegetable release spray optional

Wire pan grids optional

Pr es s an d Set COR E Temp

25 to 45 minutes 165 F 74C

Do not Open the Oven Door During the Smoking Function

Press and Set Time R

Low Temp eratur e Steam

Cus tard, baked

40 to 60 minutes

Pre ss and Set COR E Temp

Min ute s 145 F 63C

Stea m Low Temp eratur e Steam

Steam Full Spee d Low Temp eratur e Steam Ful l Speed

Stea m 212F 100 C Low Temp eratur e Steam 170F 77 C

Coat interior of each pan cup with

Press and Set

Pres s and Set

Core Pre ss and Se t Core

For Fresh or Liquid

Prehe AT the COM BIT Herm to

Mous SE

Gala Ntin E

125 To 130F 10 to 15F To 54C To 8C Shelves

Pâté en Cro ute

Load pans

Min ute s 180 F 82C

Ste am

Rice Conver ted or Lon g Grai n

212F 10 0C

20 to 30 minutes

30 to 40 minutes 140 To 160 F 60 to 71C

Tamal es

Stainless steel full-size perfor ated pans 4 100mm deep

20 x 12 x GN 1/1 530mm x 325mm x 100mm

40 to 45 minutes 190 F 88C

Press and Set Timer

30 to 35 minutes 190 F 88C

Pota toe s Red or salad variety Small

Cut, sliced, or the skin may

Pre ss and Set Core Temp

Quic K Stea M

Aspa ragus

See bel ow

Minu tes Cor n-on-th e-c ob Minutes Green Beans Pea s

Ful l-Size Perf orated pans

Error Codes and Reasons

Press and Hold the Power KEY for a Period of 5 Seconds

Press the Start KEY to Acknowledge the Error

Error Codes and Reasons

118

Conti NUE D Operation Under Error Conditio NS

Pres S the Start KEY to Acknowledge the Error

Selec T and Press ONE of the Cooking Mode S Indica TED

Preventive Maintenance

Clea N ING M AT Eria LS

PRO Tecti Stainle Teel Surface

Clea N ING a Gent S

I LY O V E N C L E a N I N G

I L Y G a S K E T C L E a N I N G

Daily Steam Generator Flush

O B E U S a G E a N D C L E a N I N G

Electric

Pres S the Chef F UNC Tion KE Y

UTO C LE a N Automa TIC Clea NIN G PR O GR AM

Clea ni ng a nd Maintenance

Forced Rinsing M ODE

T O C L E AN AU T OM AT I C C L E AN in G PR Ogram

Press the Steam Program KEY

Press the ON/OFF Power KEY

With TH E OV EN AT Room Temp ER Atur E

Unit w ill start to fil l

To c ontinue to Fl ush out al l remaining sol ution

TUR N T HE SEL ECT ION K NOB To the STE AM P Osition

Contr OL

Uni t will star t to fil l

To co ntinue to flush ou t all remainin g solution

Manu AL Steam Gene Rator F Lush

Chef F Unction K EY to confirm ca ncel latio n

PR IC E U.S. $25