CHAPTER 2

2. Manual feed (multi-purpose tray)

The presence of paper on the

When the DC controller receives the /PRNT signal from the video controller, the lifting plate solenoid (SL2) turns ON, the lifting plate is unlocked (the lifting plate rises), and the paper touches the

The lifting plate position is detected by the lifting plate position sensor (PS1302). If the sen- sor detects that the lifting plate is up while waiting, SL2 is turned ON to lower the lifting plate.

The manual feed clutch (CL3) turns ON, and the main motor (MT1) power is transmitted to the manual feeding

Paper pressed against the manual feeding

The CPU turns ON SL2 to lower the lifting plate. If it is normal, the lifting plate position sen- sor detects the lifting plate within about 0.5 seconds. The CPU notifies the video controller of a lifting plate position failure if the lifting plate position sensor fails to detect the lifting plate 5 times in a row when the CPU repeats this operation 5 times.

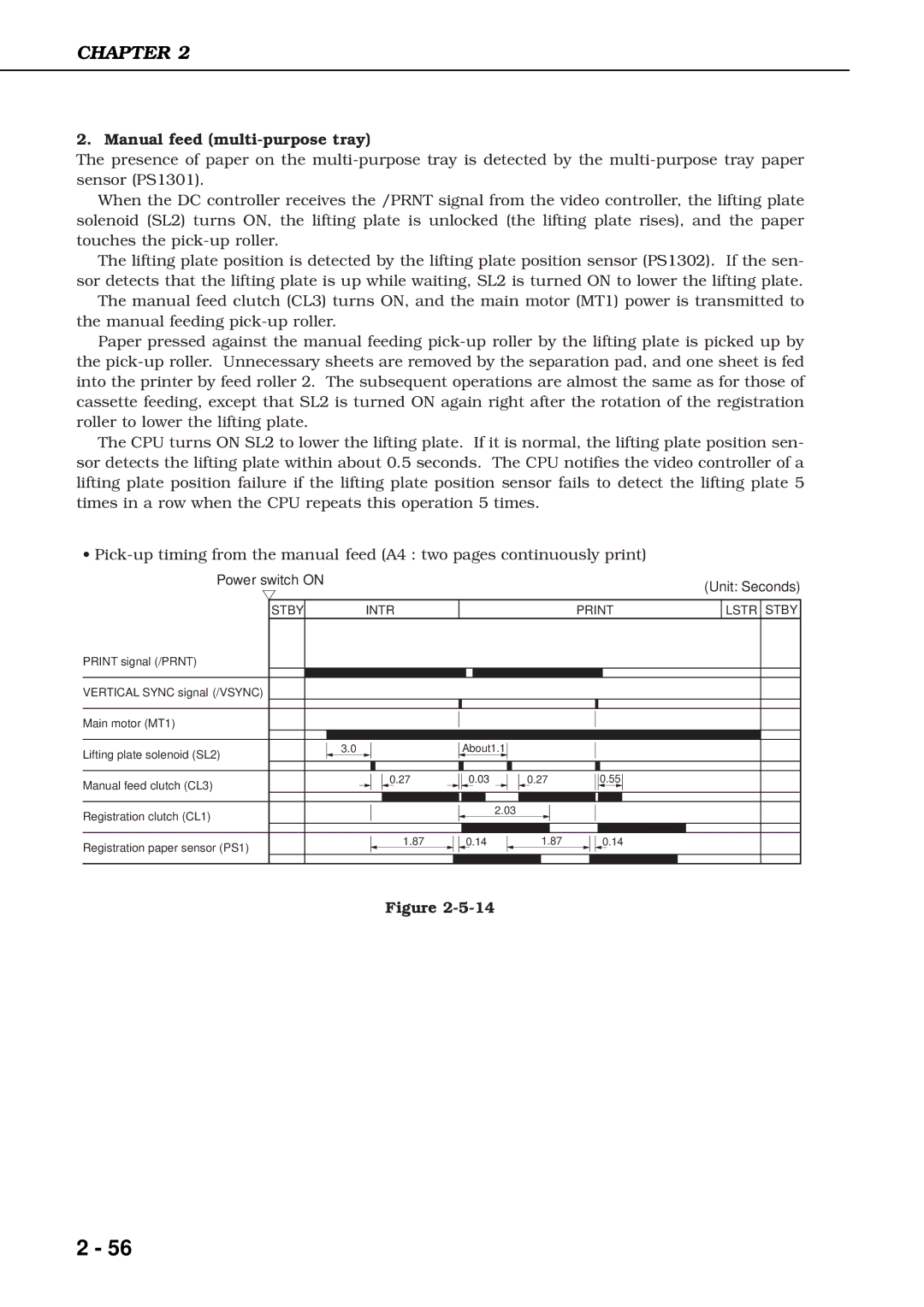

•

Power switch ON |

|

|

|

| (Unit: Seconds) |

|

|

|

|

| |

STBY | INTR |

|

| LSTR STBY | |

PRINT signal (/PRNT) |

|

|

|

|

|

VERTICAL SYNC signal (/VSYNC) |

|

|

|

|

|

Main motor (MT1) |

|

|

|

|

|

Lifting plate solenoid (SL2) | 3.0 | About1.1 |

|

|

|

|

|

|

|

| |

Manual feed clutch (CL3) | 0.27 | 0.03 | 0.27 | 0.55 |

|

|

|

|

|

| |

Registration clutch (CL1) |

| 2.03 |

|

|

|

|

|

|

|

| |

Registration paper sensor (PS1) | 1.87 | 0.14 | 1.87 | 0.14 |

|

|

|

|

|

| |

| Figure |

|

|

| |

2 - 56