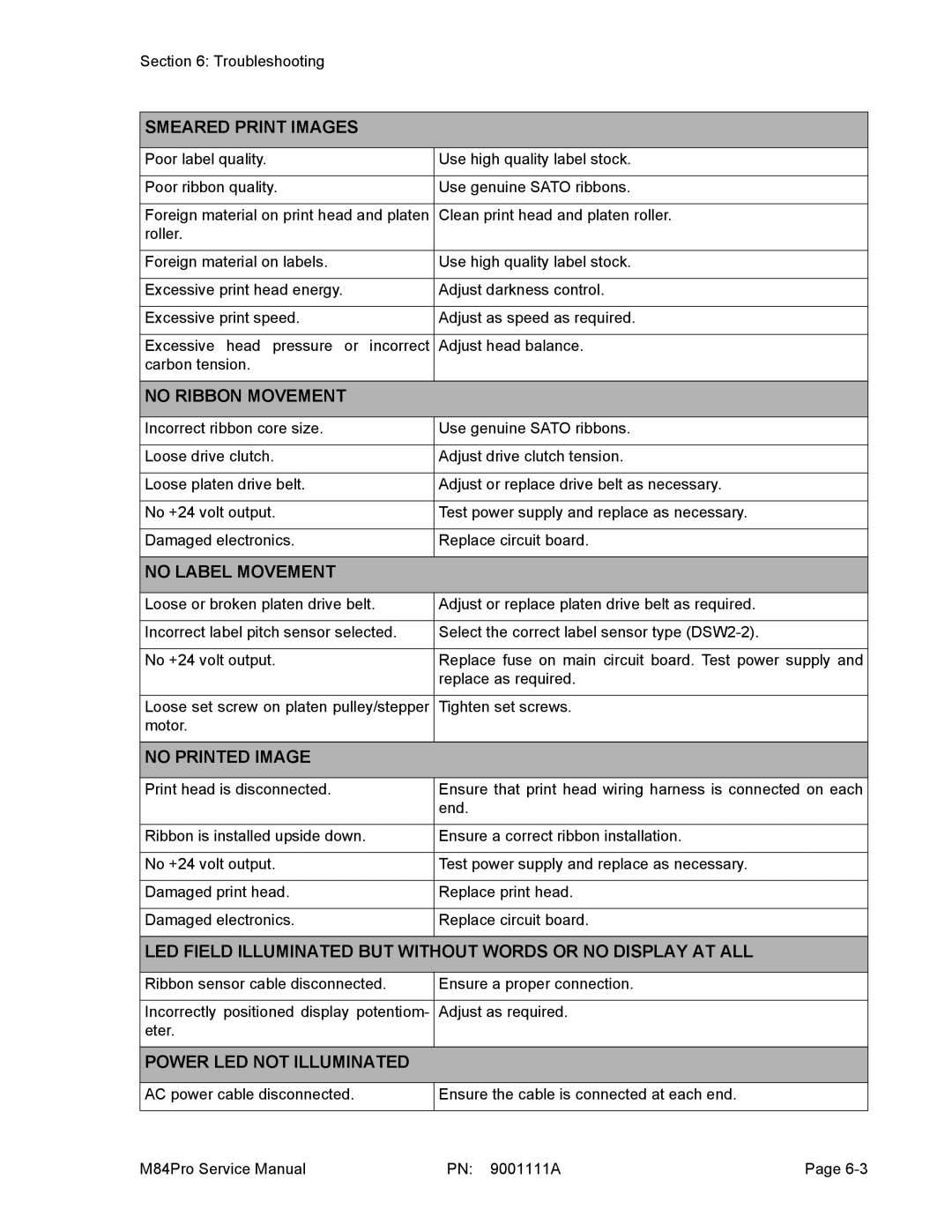

Section 6: Troubleshooting

SMEARED PRINT IMAGES

Poor label quality. | Use high quality label stock. |

|

|

Poor ribbon quality. | Use genuine SATO ribbons. |

|

|

Foreign material on print head and platen | Clean print head and platen roller. |

roller. |

|

|

|

Foreign material on labels. | Use high quality label stock. |

|

|

Excessive print head energy. | Adjust darkness control. |

|

|

Excessive print speed. | Adjust as speed as required. |

|

|

Excessive head pressure or incorrect | Adjust head balance. |

carbon tension. |

|

|

|

NO RIBBON MOVEMENT |

|

|

|

Incorrect ribbon core size. | Use genuine SATO ribbons. |

|

|

Loose drive clutch. | Adjust drive clutch tension. |

|

|

Loose platen drive belt. | Adjust or replace drive belt as necessary. |

|

|

No +24 volt output. | Test power supply and replace as necessary. |

|

|

Damaged electronics. | Replace circuit board. |

|

|

NO LABEL MOVEMENT |

|

|

|

Loose or broken platen drive belt. | Adjust or replace platen drive belt as required. |

|

|

Incorrect label pitch sensor selected. | Select the correct label sensor type |

|

|

No +24 volt output. | Replace fuse on main circuit board. Test power supply and |

| replace as required. |

|

|

Loose set screw on platen pulley/stepper | Tighten set screws. |

motor. |

|

|

|

NO PRINTED IMAGE |

|

|

|

Print head is disconnected. | Ensure that print head wiring harness is connected on each |

| end. |

|

|

Ribbon is installed upside down. | Ensure a correct ribbon installation. |

|

|

No +24 volt output. | Test power supply and replace as necessary. |

|

|

Damaged print head. | Replace print head. |

|

|

Damaged electronics. | Replace circuit board. |

|

|

LED FIELD ILLUMINATED BUT WITHOUT WORDS OR NO DISPLAY AT ALL | |

|

|

Ribbon sensor cable disconnected. | Ensure a proper connection. |

|

|

Incorrectly positioned display potentiom- | Adjust as required. |

eter. |

|

|

|

POWER LED NOT ILLUMINATED |

|

|

|

AC power cable disconnected. | Ensure the cable is connected at each end. |

|

|

M84Pro Service Manual | PN: 9001111A | Page |