3-48 FUEL SYSTEM (DFI)

Fuel Injectors (Service

•Replace the seals [A] with new ones.

•Apply grease to the inside and outside of seals.

•Install:Delivery Pipe Assembly

Collars

•Install the clamps [A] as shown.

•Tighten:

Torque - Delivery Pipe Mounting Bolts: 7.8 N·m (0.80 kgf·m, 69 in·lb)

•Install the fuel hoses (see Cable, Wire, and Hose Routing section in Appendix chapter).

○For

Audible Inspection

•Start the engine.

•Apply the tip of a screwdriver [A] to the injector [B]. Put the grip end onto your ear, and listen whether the injector is clicking or not.

•A sound scope can also be used.

•Do the same for the other injector.

![]() If all the injectors click at a regular intervals, the injectors are good.

If all the injectors click at a regular intervals, the injectors are good.

○The click interval becomes shorter as the engine speed rises.

![]() If either injector doesn’t click, perform the “Injector Signal Test” for injector operation.

If either injector doesn’t click, perform the “Injector Signal Test” for injector operation.

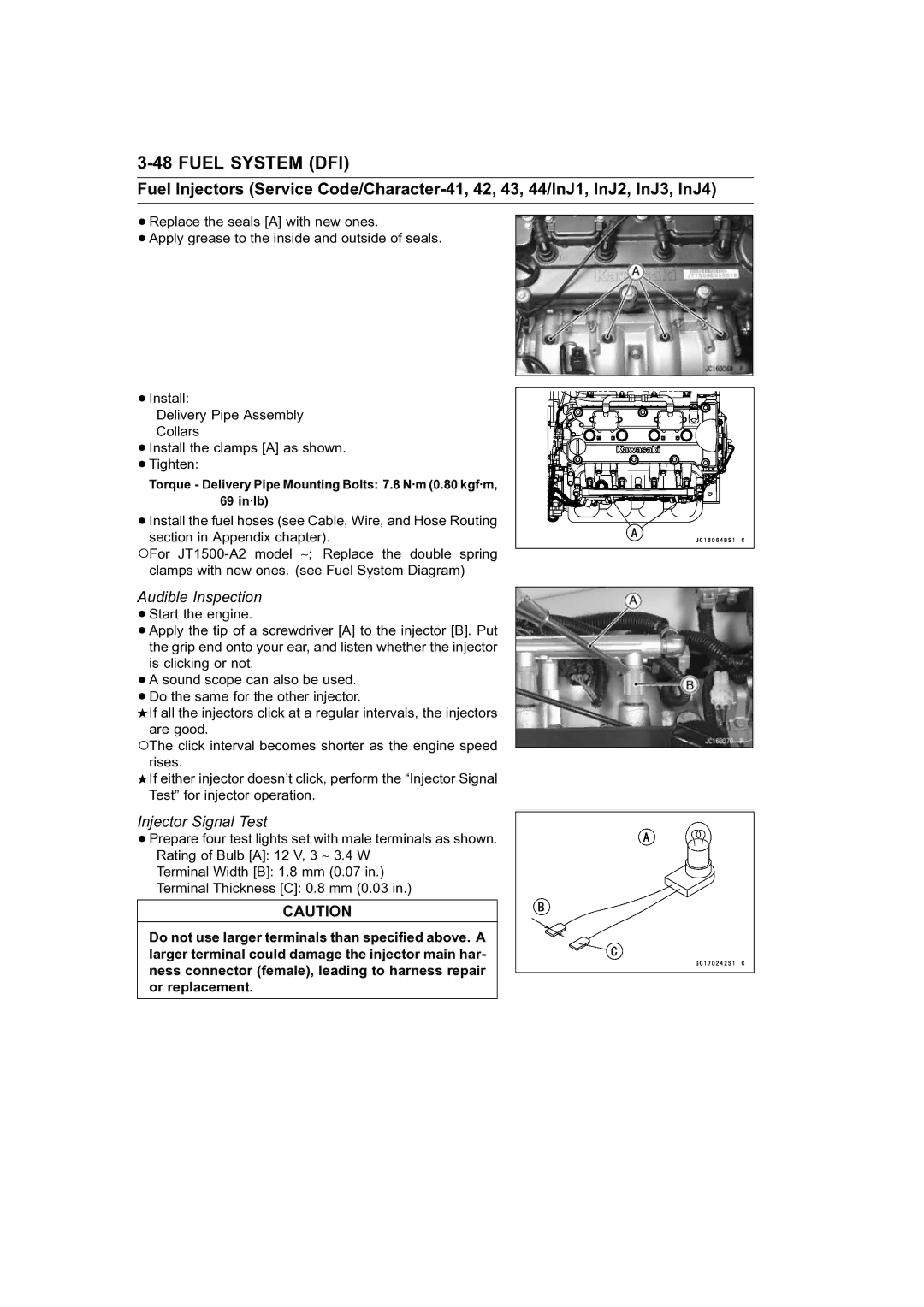

Injector Signal Test

•Prepare four test lights set with male terminals as shown. Rating of Bulb [A]: 12 V, 3 ∼ 3.4 W

Terminal Width [B]: 1.8 mm (0.07 in.)

Terminal Thickness [C]: 0.8 mm (0.03 in.)

CAUTION

Do not use larger terminals than specified above. A larger terminal could damage the injector main har- ness connector (female), leading to harness repair or replacement.