2-24 PERIODIC MAINTENANCE

Periodic Maintenance Procedures

•Check that the battery terminals [B] are not corroded.

![]() If necessary, remove the battery (see Electrical System chapter) and clean the terminals and cable ends using a solution of baking soda and water.

If necessary, remove the battery (see Electrical System chapter) and clean the terminals and cable ends using a solution of baking soda and water.

•After attaching both cables, coat the terminals and cable ends with grease to prevent corrosion.

•Install the battery (see Electrical System chapter).

Spark Plug Cleaning and Inspection

•Remove:

Seat (see Hull/Engine Hood chapter)

Spark Plug Caps

•Remove[A]. the spark plugs using the 16 mm plug wrench

Owner’s Tool - Spark Plug Wrench, 16 mm:

•Clean the spark plug, preferably in a sandblasting device, and then clean off any abrasive particles. The plug may also be cleaned using a

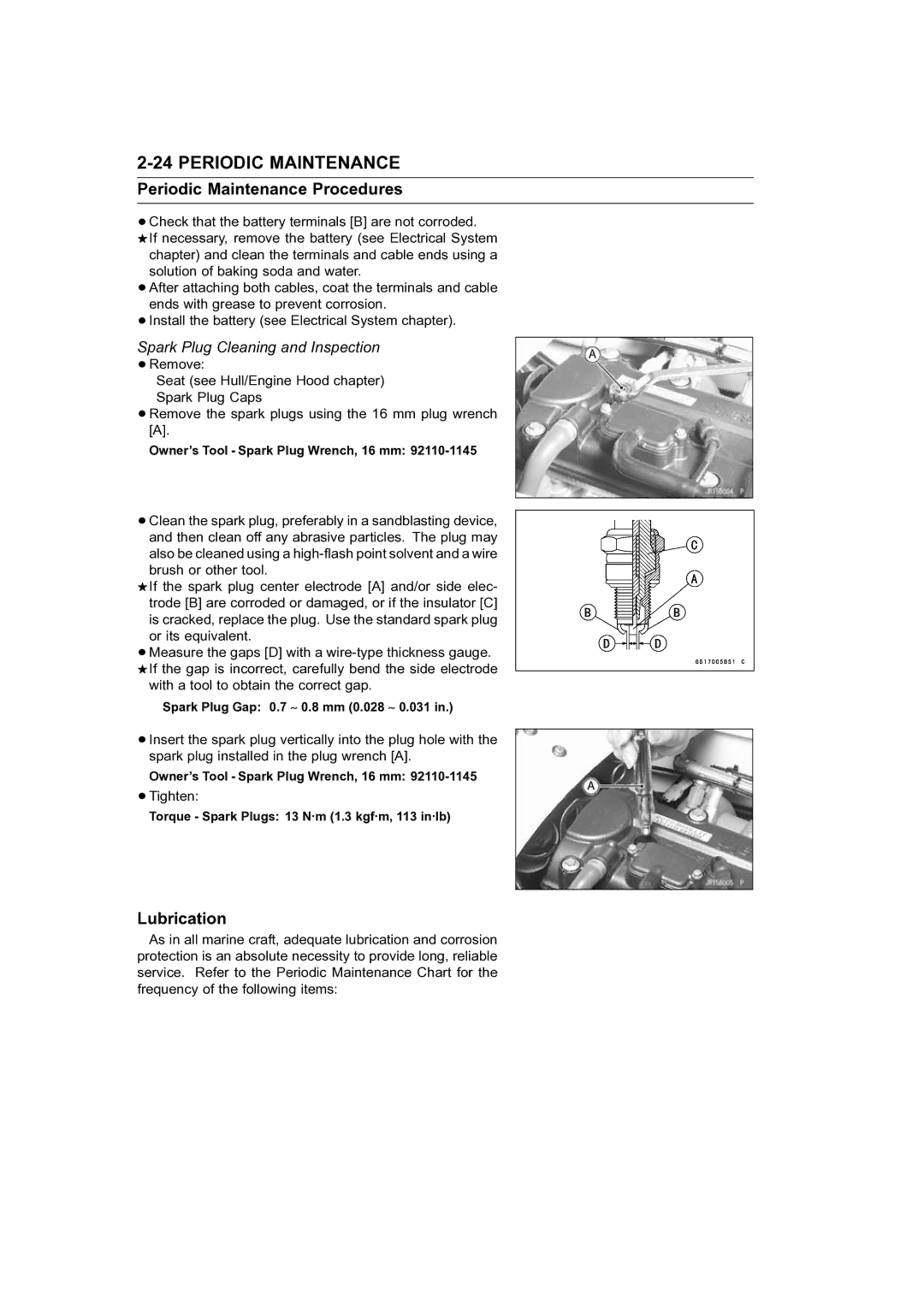

![]() If the spark plug center electrode [A] and/or side elec- trode [B] are corroded or damaged, or if the insulator [C] is cracked, replace the plug. Use the standard spark plug or its equivalent.

If the spark plug center electrode [A] and/or side elec- trode [B] are corroded or damaged, or if the insulator [C] is cracked, replace the plug. Use the standard spark plug or its equivalent.

•Measure the gaps [D] with a ![]() If the gap is incorrect, carefully bend the side electrode

If the gap is incorrect, carefully bend the side electrode

with a tool to obtain the correct gap.

Spark Plug Gap: 0.7 ∼ 0.8 mm (0.028 ∼ 0.031 in.)

•Insert the spark plug vertically into the plug hole with the spark plug installed in the plug wrench [A].

Owner’s Tool - Spark Plug Wrench, 16 mm:

•Tighten:

Torque - Spark Plugs: 13 N·m (1.3 kgf·m, 113 in·lb)

Lubrication

As in all marine craft, adequate lubrication and corrosion protection is an absolute necessity to provide long, reliable service. Refer to the Periodic Maintenance Chart for the frequency of the following items: