JET SKI Watercraft

Page

Quick Reference Guide

Page

JET SKI Watercraft

List of Abbreviations

Fuel Information

Emission Control Information

Exhaust Emission Control System

Foreword

Page

Page

General Information

Smart Learning Operation mode SLO JT1500-A2 model ∼

Auxiliary Cooling

Kawasaki Diagnostic System KDS Software

Adjustments

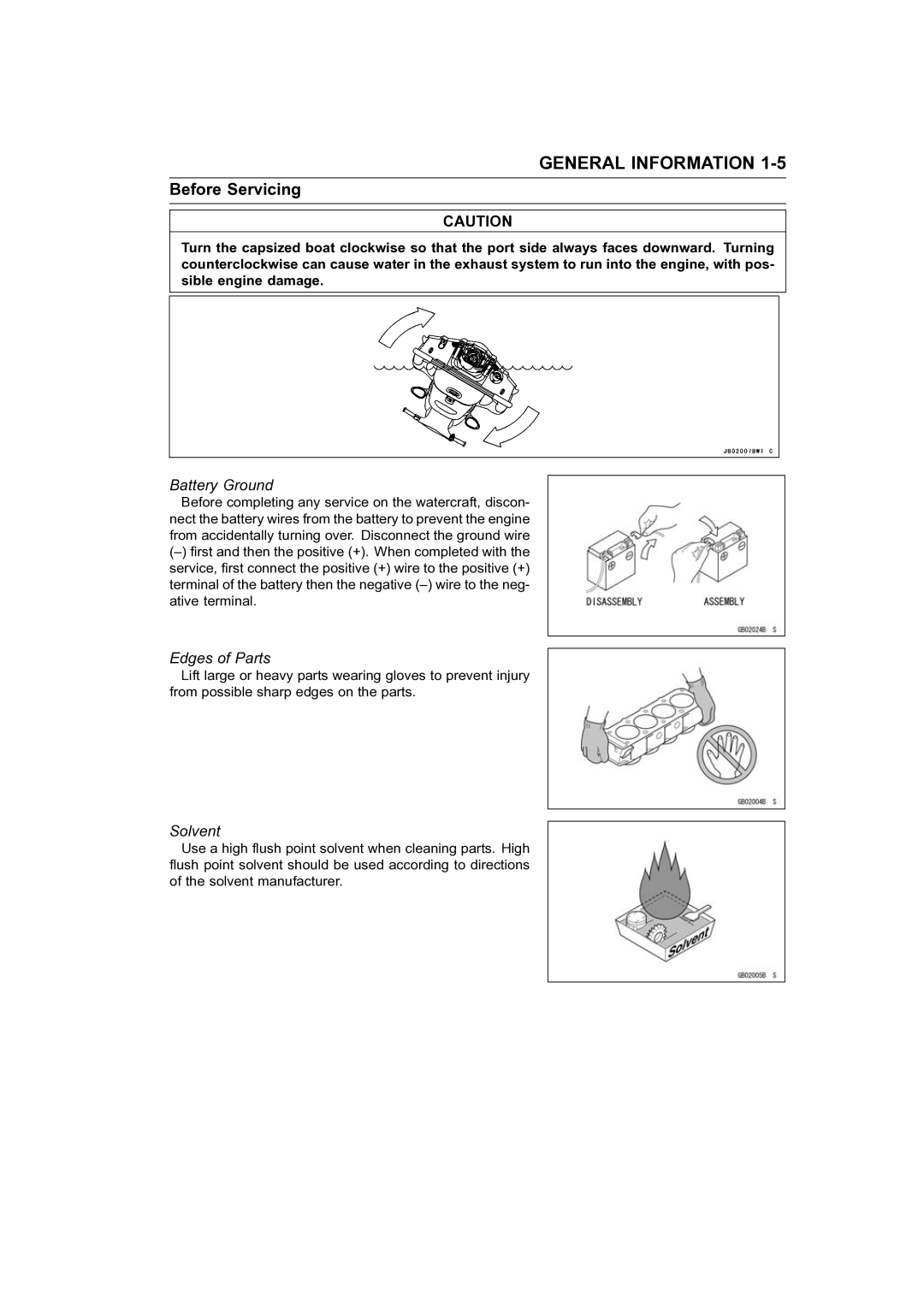

Before Servicing

General Information

Battery Ground

Edges of Parts

Solvent

Storage of Removed Parts

Cleaning Watercraft before Disassembly

Arrangement and Cleaning of Removed Parts

Replacement Parts

Gasket, O-ring

Assembly Order Tightening Sequence

Tightening Torque

Force

Oil Seal, Grease Seal

Liquid Gasket, Locking Agent

Press

Ball Bearing

Direction of Engine Rotation

Circlips, Cotter Pins

Electrical Wires

Lubrication

Model Identification

General Specifications

Items JT1500-A1 ∼ A2

Engine Oil

Electrical Equipment

Units of Mass

Units of Volume Units of Pressure

Units of Force Units of Power

Unit Conversion Table Prefixes for Units Units of Length

Page

Periodic Maintenance

Periodic Maintenance Chart

Torque and Locking Agent

Fastener Torque Remarks Kgf·m Ft·lb Fuel System

Engine Lubrication System

Fastener Torque Remarks Kgf·m

Exhaust System

Engine Top End

Pump and Impeller

Engine Removal/Installation

Engine Bottom End

Cooling and Bilge Systems

Electrical System

Fastener Torque Remarks Kgf·m Ft·lb

Steering

Hull/Engine Hood

Threads dia. mm Torque Kgf·m Ft·lb

General Fasteners stainless bolt and nut

Standard Service Limit Fuel System

Specifications

Special Tools and Sealant

Periodic Maintenance Procedures Fuel System

Air Filter Drain Caps Inspection and Cleaning

Throttle Control System Inspection

Periodic Maintenance Procedures

Air Filter Inspection and Cleaning

Fuel Vent Check Valve Inspection

Engine Oil Change

Fuel Pump Screen Cleaning

Engine Lubrication System

Throttle Shaft Spring Inspection

Dry

Oil Filter Replace

Periodic Maintenance Procedures Engine Top End

Air Suction Valve Inspection

Valve Clearance Inspection

Periodic Maintenance

Inlet Valve Clearance Adjustment Chart

Exhaust Valve Clearance Adjustment Chart

Coupling Damper Inspection

Engine Bottom End

Cooling and Bilge Systems

Engine Mounting Bolts Inspection and Tightness

Periodic Maintenance

Bilge System Flushing

Steering Cable/Shift Cable Inspection

Periodic Maintenance Procedures Pump and Impeller

Steering

Impeller Inspection

Electrical System

Battery Charging Condition Inspection

Battery Terminals Inspection

Hull/Engine Hood

Lubrication

Spark Plug Cleaning and Inspection

Steering Cable Ball Joint a at Steering Shaft

Lubricate the following with a penetrating rust inhibitor B

Nuts, Bolts, and Fasteners Tightness Inspection

Hose and Hose Connect Inspection

Nut, Bolt and Fastener to be checked

JT1500-A2 ∼

Rubber Strap Inspection

Page

Fuel System DFI

Fuel System DFI

Fuel System Diagram

Exploded View

Fastener Torque Remarks Kgf·m Ft·lb

Fuel System DFI

Fastener Torque Remarks Kgf·m

Fuel System DFI

Fastener Torque Remarks Kgf·m Ft·lb

Digital Fuel Injection System

Standard

Fuel System DFI

Special Tools and Sealant

DFI Parts Location

Fuel System DFI

Dummy

DFI System

Part Name

Terminal Names

Terminal Numbers of ECU Connectors

DFI Servicing Precautions

For JT1500-A2 ∼

Silicone Sealant Kawasaki Bond 56019-120 -Seals Connector

User Mode

Dealer Mode

Self-Diagnosis Self-diagnosis Outline

JT1500-A1

Self-Diagnosis Service Code Character Table

Possible Problems Fail-Safe Function

Displayed on

Self-Diagnosis

Memory of Service Code Character

Watercraft conditions when problem occurred

Troubleshooting the DFI System Sample Diagnosis Sheet

Troubleshooting the DFI System

Throttle Sensor Removal/Adjustment

Throttle Sensor Service Code/Character-11/tPS

Input Voltage Inspection

Be sure the battery is fully charged

Input Voltage at ECU Standard 4.75 ∼ 5.25 V DC

Output Voltage Inspection

Resistance Inspection

ECU Joint Connector E Throttle Sensor

Inlet Air Pressure Sensor Service Code/Character-12/bOSt

Inlet Air Pressure Sensor Installation

Inlet Air Pressure Sensor Removal

Input Voltage at Sensor Connector Standard 4.75 ∼ 5.25 V DC

Joint Connector E Inlet Air Pressure Sensor

Inlet Air Temperature Removal/Installation

Inlet Air Temperature Sensor Service Code/Character-13/AIrt

Sensor Resistance Inspection

Fuel System DFI

Water Temperature Sensor Removal/Installation

Water Temperature Sensor Service Code/Character-14/AqUt

Output Voltage at ECU Standard about 3 ∼ 4 V at 20C 68F

ECU Joint Connector E Water Temperature Sensor

Crankshaft Sensor Service Code/Character-21/CrAg

Crankshaft Sensor Removal/Installation

Crankshaft Sensor Inspection

Camshaft Position Sensor Service Code/Character-23/CAAg

Camshaft Position Sensor Removal/Installation

Camshaft Position Sensor Inspection

Vehicle-down Sensor Service Code/Character-31/dOS

Vehicle-down Sensor Installation

Vehicle-down Sensor Removal

Vehicle-down Sensor Inspection

Fuel System DFI

Fuel Injector Removal

Fuel Injector Installation

Audible Inspection

Injector Signal Test

Injector Unit Test

Injector Resistance Inspection

Injector Voltage Inspection

Injector Fuel Line Inspection

ECU

Ignition Coil Removal/Installation

Ignition Coils Service Code/Character-51, 52/COL1, COL2

Fuel System DFI

Possible Causes Action Chapter

Engine Overheating Service Code/Character-71/HEAt

Low Engine Oil Pressure Service Code/Character-72/OILP

Oil Temperature Sensor Removal/Installation

Sensor Resistance Inspection

JT1500-A2 model ∼

Engine Oil Overheating Service Code/Character-76/OILH

ECU Installation

ECU Power Supply Inspection

ECU Removal

ECU connector B in this chapter figure

ECU Power Source Circuit

Main Fuse Inspection

DFI Power Source

Relay Assembly Removal

Relay Assembly Inspection

Fuel Pump Relay

Relay Coil Terminals 6 Relay Switch Terminals 5

Free Play Inspection

Throttle Cable Adjustment

Throttle Case Removal/Disassembly

Throttle Lever, Cable and Case

Throttle Case Assembly/Installation

Throttle Cable Removal

Throttle Cable Installation

Throttle Cable Inspection

Throttle Case and Cable Lubrication

Air Filter Installation

Air Filter

Air Filter Removal

Air Filter Assembly

Air Filter Disassembly

Throttle Body Assy

ISC Idle Speed Controller Inspection

ISC Idle Speed Controller Removal/Installation

ISC a

ISC Resistance Inspection

Inlet Manifold Removal

Inlet Manifold

Inlet Manifold Installation

Fuel System DFI

Fuel Pressure Inspection

Fuel Line

Fuel Flow Rate Inspection

Amount of Fuel Flow Standard 67 mL or more for 3 seconds

Fuel Vent Check Valve Mounting

Fuel Vent Check Valve

Fuel Filter Removal

Fuel Filter

Fuel Filter Installation

Fuel Pump

Fuel Pump Removal

JT1500-A2 ∼ model

Power Source Voltage Inspection

Fuel Pump Installation

Operating Voltage Inspection

Fuel Pump Relay Inspection

Fuel Pump Relay Removal

Fuel Tank Removal

Fuel Tank

Fuel Tank Cleaning

Fuel Tank Installation

Fuel Filler and Tube Removal

Fuel Filler and Tube Installation

Engine Lubrication System

Exploded View

Fastener Torque Remarks Kgf·m Ft·lb

Engine Oil Flow Chart

Passage

Oil Pressure Measurement

Special Tool and Sealant

Engine Oil and Oil Filter

Oil Level Inspection

Preliminary Check

Ordinary standard Check

Oil Filter Replacement

Oil Cooler Installation

Oil Cooler

Oil Cooler Removal

Oil Cooler Assembly

Oil Cooler Disassembly

Oil Cooler Inspection

Oil Separator Tank Removal

Breather Case Installation

Breather Case and Oil Separator Tank

Breather Case Removal

Blowby Gas System Inspection

Oil Separator Tank Installation

Oil Pan Installation

Oil Pan

Oil Pan Removal

Oil Pump Sprocket Installation

Oil Pump Sprocket, Oil Pump and Oil Pressure Relief Valve

Oil Pump Sprocket Removal

Oil Pump Removal

Oil Pump Installation

Oil Screen Installation

Oil Pump Inspection

Oil Screen Removal

Oil Pump Sprocket Chain Removal

Oil Pressure Relief Valve Inspection

Oil Pressure Measurement

Oil Pressure Measurement

Engine Lubrication System

Oil Pressure Switch

Oil Pressure Switch Removal

Oil Pressure Switch Installation

Page

Exhaust System

Exploded View

Fastener Torque Remarks Kgf·m

Exhaust Manifold Removal

Exhaust Manifold

Exhaust Manifold Installation

Exhaust Manifold Cleaning and Inspection

Exhaust Pipe Installation

Exhaust Pipe

Exhaust Pipe Removal

Exhaust Pipe Cleaning and Inspection

Water Box Muffler Installation

Water Box Muffler

Water Box Muffler Removal

Water Box Muffler Inspection

Engine Top End

Exploded View

Fastener

Engine TOP END

Engine TOP END

Fastener Torque Remarks Kgf·m

Standard Service Limit Camshafts

Cylinder Head

Valves

Cylinder, Piston

Standard Service Limit

Special Tools and Sealant

Engine TOP END

Engine TOP END

Air Suction Valve Removal

Clean Air System

Air Suction Valve Installation

Clean Air System Hose Inspection

Cylinder Head Cover Installation

Cylinder Head Cover

Cylinder Head Cover Removal

Camshaft Chain Tensioner Installation

Camshaft Chain Tensioner

Camshaft Chain Tensioner Removal

Camshaft Removal

Camshaft, Camshaft Chain

Camshaft Installation

Piston TDC Finding

Special Tool TDC Measurement Tool

Camshaft Runout

Camshaft, Camshaft Cap Wear

Camshaft Chain Removal

Cylinder Compression Measurement

Cylinder Head

Cylinder Head Removal

Cylinder Head Installation

Cylinder Head Warp

Valve Removal

Valve Installation

Valves

Valve Clearance Check

Valve-to-Guide Clearance Measurement Wobble Method

Valve Guide Installation

Valve Seat Repair

Valve Seat Inspection

Operating Procedures

Seat Cutter Operation Care

Marks Stamped on the Cutter

Engine TOP END

Engine TOP END

Engine TOP END

Cylinder, Pistons

Cylinder Removal

Piston Removal

Oil ring rails have no top or bottom

Piston/Cylinder Installation

With the Special Tools

With the Hand

Piston Ring Groove Width

Cylinder Wear

Piston Wear

Piston Ring, Piston Ring Groove Wear

Piston Ring End Gap

Piston Ring Thickness

Page

Engine Removal/Installation

Exploded View

Fastener Torque Remarks Kgf·m

Engine Removal

Engine Removal/Installation

Engine Damper Removal

Engine Installation

Engine Damper Installation

Engine Bottom End

Exploded View

Fastener Torque Remarks Kgf·m

Connecting Rod Big End Bearing Insert Selection

Standard Service Limit Crankshaft, Connecting Rods

Crankshaft Main Journal Diameter 40.984 ∼ 41.000 mm 40.96 mm

Special Tools and Sealant

Kawasaki Bond Liquid Gasket Black

Coupling/Output Shaft Removal

Coupling

Coupling/Output Shaft Installation

Output Cover Oil Seal Replacement

Ball Bearing Inspection

Magneto Cover Bearing Replacement

Oil Seal Inspection

Ball Bearing Lubrication

Magneto Flywheel Installation

Magneto Flywheel

Magneto Flywheel Removal

InstallMagneto Cover see Coupling/Output Shaft Installation

Stator Installation

Stator

Stator Removal

Crankcase Splitting

Crankcase Splitting

Crankcase Assembly

Following the sequence numbers, tighten the M8 bolts

Crankshaft and Connecting Rods

Crankshaft Installation

Crankshaft Removal

Connecting Rod Installation

Connecting Rod Removal

Engine Bottom END

Be careful not to overtighten the nuts

Connecting Rod Bend

Connecting Rod Twist

Connecting Rod Big End Side Clearance

Connecting Rod Big End Bearing Insert/Crankpin Wear

92139-3709

Crankshaft Main Bearing Insert/Journal Wear

Marking Position

Crankshaft

Crankshaft Side Clearance

Crankshaft Runout

Measure the crankshaft runout

Cooling and Bilge Systems

Exploded View

Fastener Torque Remarks Kgf·m

Breather Removal

Breather Installation

Breather Cleaning and Inspection

Bilge System

Filter Cleaning and Inspection

Filter Installation

Hose Inspection

Hose Installation

Cooling and Bilge System Hoses

Hose Removal

Cooling and Bilge System Flushing

Cooling and Bilge System Flow Diagram

Cooling and Bilge Systems

Water Pipe Installation

Water Pipe

Water Pipe Removal

After Submerging

Summary Procedures after Submerging

Cooling and Bilge Systems

Detailed Procedures after Submerging

Cooling and Bilge Systems

Cooling and Bilge Systems

Page

Drive System

Exploded View

Fastener Torque Remarks Kgf·m

Standard Service Limit Drive Shaft

Specification

Drive System

Drive Shaft Removal/Installation

Drive Shaft Holder Removal/Disassembly

Drive Shaft/Drive Shaft Holder

Drive Shaft Holder Assembly/Installation

Drive Shaft Runout

Pump and Impeller

Exploded View

Fastener Torque Remarks Kgf·m

Standard Service Limit Jet Pump

Pump and Impeller

Pump Removal

Pump Installation

Torque Pump Mounting Bolts 36 N·m 3.7 kgf·m, 27 ft·lb

Pump Disassembly

Special Tool Oil Seal & Bearing Remover 57001-1058 a

JT1500-A1,A2 ∼

Pump Assembly

Special Tool Bearing Driver Set

Pump and Impeller

JT1500-A1, A2 ∼

Impeller Clearance

Water Filter Cover Removal/Installation

Impeller Outside Diameter Measurement

Pump Inspection

Page

Steering

Exploded View

36 ∼

Special Tool and Sealant

Steering Cable Adjustment

Steering Cable

Steering Cable Removal

Special Tool Box Wrench

Steering Cable Installation

Steering Cable Inspection

Steering Cable Lubrication

Handlebar Removal

Handlebar

Handlebar Installation

Steering

Steering Removal

Steering

Steering

Steering Installation

Torque the steering shaft locknut a

Steering

Shift Cable Adjustment

Reverse System

Shift Cable Removal

Steering

Shift Cable Installation

Shift Cable Inspection

Shift Cable Lubrication

Shift Lever Shaft Removal/Installation

Reverse Bucket Removal/Installation

Hull/Engine Hood

Exploded View

Fastener Torque Remarks Kgf·m

HULL/ENGINE Hood

HULL/ENGINE Hood

Front Storage Compartment Cover Removal

Seat Installation

Fittings

Seat Removal

Front Storage Compartment Cover Disassembly

Front Storage Compartment Cover Assembly

Mirror Installation

Mirror Removal

Mirror Stay Removal

Mirror Stay Installation

Crossmember Removal

Front Storage Pocket Installation

Storage Pocket Disassembly/Assembly

Front Storage Pocket Removal

Crossmember Installation

Exhaust Outlet Installation

Handrail Installation

Drain Plug Housing Removal

Drain Plug Housing Installation

Reboarding Step Removal

Stabilizer Installation

Reboarding Step Installation

Stabilizer Removal

Hull Replacement

Rubber Parts Location

Rubber Parts

HULL/ENGINE Hood

Rivet Removal

Rivet Installation

Front Bumper Installation

Rear Bumper Installation

Side Bumper Removal

Side Bumper Installation

Page

Electrical System

Electrical System

Parts Location

Electrical System

Electrical System

Exploded View

30 ∼ 40 in·lb Starter Cable Mounting Nuts

Electrical System

Fastener Torque Remarks Kgf·m

Electrical System

Electrical System

Wiring Diagram

Electrical System

JT1500-A2 ∼

Electrical System

Ignition System

Standard Service Limit Battery

Electric Starter System

Charging System

Electrical System

Precautions

Electrical Connectors Female Connectors a Male Connectors B

Wiring Inspection

Electrical Wiring

Electrolyte Filling

Battery

Installation

Removal

Electrical System

Initial Charge

Precautions

Interchange

Charging Condition Inspection

Refreshing Charge

Electrical System

Starter Relay Inspection

Starter Relay Installation

Electric Starter System

Starter Relay Removal

Starter Motor Removal

Starter Motor Installation

Starter Motor Assembly

Starter Motor Disassembly

Brush Inspection

Commutator Cleaning and Inspection

Armature Inspection

Brush Lead Inspection

Brush Plate and Terminal Bolt Inspection

Reduction Gear Inspection

Reduction Gear Removal/Installation

Electrical System

Regulator/Rectifier Removal/Installation

Charging System

Magneto Output Voltage

Regulator Inspection

Regulator/Rectifier Inspection

Charging System Circuit

Electrical System

Crankshaft Sensor Installation

Ignition System

Crankshaft Sensor Removal

Timing Rotor Removal

Timing Rotor Installation

Ignition Coil Removal

Ignition Coil Installation

Ignition Coil Inspection

Measuring arcing distance

Measuring coil resistance

Camshaft Position Sensor Installation

Camshaft Position Sensor Removal

Measuring spark plug lead resistance

Igniter Inspection

Igniter Removal/Installation

Ignition Coil Primary Peak Voltage Standard 250 V or more

Camshaft Position Sensor Peak Voltage Inspection

Crankshaft Sensor Peak Voltage Check

Spark Plug Removal

Spark Plug Installation

Spark Plug Adjustment

Spark Plug Cleaning

Ignition System Circuit

Electrical System

Steering Position Sensor and Magnet Installation

Kawasaki Smart Steering System

Steering Position Sensor and Magnet Removal

Steering Position Sensor Clearance

Inspection of Kawasaki Smart Steering System

Steering Position Sensor Input Voltage Inspection

Steering Position Sensor Output Voltage Inspection

Steering Position Sensor Circuit

Speed Sensor Removal/Installation

Sensors

Speed Sensor Inspection

Fuel Level Sensor Inspection

Throttle Sensor Removal/Installation

Throttle Sensor Inspection

Water Temperature Sensor Inspection

Inlet Air Temperature Sensor Inspection

Oil Temperature Sensor Inspection

Display Function Inspection

Multifunction Meter

MODE/SET Button Inspection

Speedometer Inspection

Speed Sensor Electric Source Inspection

Tachometer Inspection

Battery Symbol/bAt Characters/LED Inspection

Buzzer Inspection

Electrical System

Circuit Inspection

Relay Assembly

Relay Assembly Circuit Inspection with the battery connected

Switch Inspection

Switches

Fuse

Page

Storage

Engine Oil

Preparation for Storage

Cooling System

Bilge System

Engine

Engine Mounting Bolts

Battery

Do not allow any soda solution to enter the battery

Air Filter

General

General Inspection

Removal from Storage

Test Run

Page

Appendix

Cable, Wire and Hose Routing

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Troubleshooting Guide

Engine Doesn’t Start, Starting Difficulty

Poor Running at Low Speed

Poor Running or No Power at High Speed

Oil Pressure Warning Light Goes On

Overheating

Over Cooling

Abnormal Engine Noise

Runs Properly

Engine Activates Slow Down Mode

Battery Trouble

Poor Performance through Engine

Model Application