3-50 FUEL SYSTEM (DFI)

Fuel Injectors (Service

Injector Voltage Inspection

•Turn the ignition switch OFF.

•Connect a digital voltmeter [A] to the connector [B], with the needle adapter set.

Special Tool - Needle Adapter Set:

Injector Power Source Voltage

Connector to Injector #1, #2, #3, #4

Meter (+) → R/Y lead

Meter

•Turn the ignition switch ON and push the lanyard key un- der the stop button.

•Pushing the start button, run the engine 5 ∼ 6 seconds at idling to measure the injector power source voltage.

○Wait 15 seconds before using the starter again.

Power Source Voltage at Injector Connector

Standard: Battery Voltage

![]() If the power source voltage is less than standard, check the wiring (see Wiring Diagram in this section), relay (Main Relay Inspection) and ECU power source (see ECU Power Supply Inspection).

If the power source voltage is less than standard, check the wiring (see Wiring Diagram in this section), relay (Main Relay Inspection) and ECU power source (see ECU Power Supply Inspection).

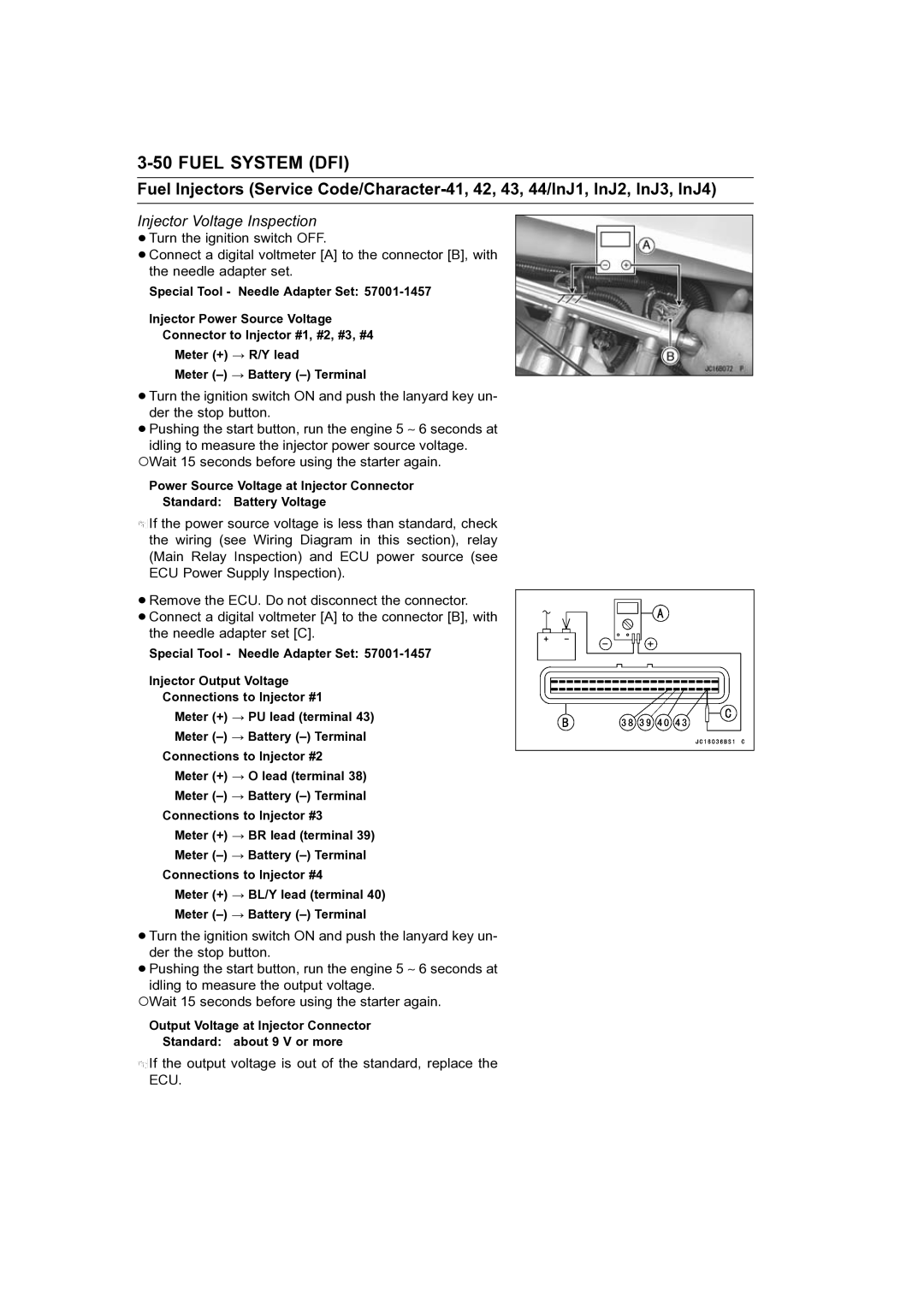

•Remove the ECU. Do not disconnect the connector.

•Connect a digital voltmeter [A] to the connector [B], with the needle adapter set [C].

Special Tool - Needle Adapter Set:

Injector Output Voltage

Connections to Injector #1

Meter (+) → PU lead (terminal 43)

Meter

Connections to Injector #2

Meter (+) → O lead (terminal 38)

Meter

Connections to Injector #3

Meter (+) → BR lead (terminal 39)

Meter

Connections to Injector #4

Meter (+) → BL/Y lead (terminal 40)

Meter

•Turn the ignition switch ON and push the lanyard key un- der the stop button.

•Pushing the start button, run the engine 5 ∼ 6 seconds at idling to measure the output voltage.

○Wait 15 seconds before using the starter again.

Output Voltage at Injector Connector

Standard: about 9 V or more

![]() If the output voltage is out of the standard, replace the ECU.

If the output voltage is out of the standard, replace the ECU.