Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

INSTALLATION

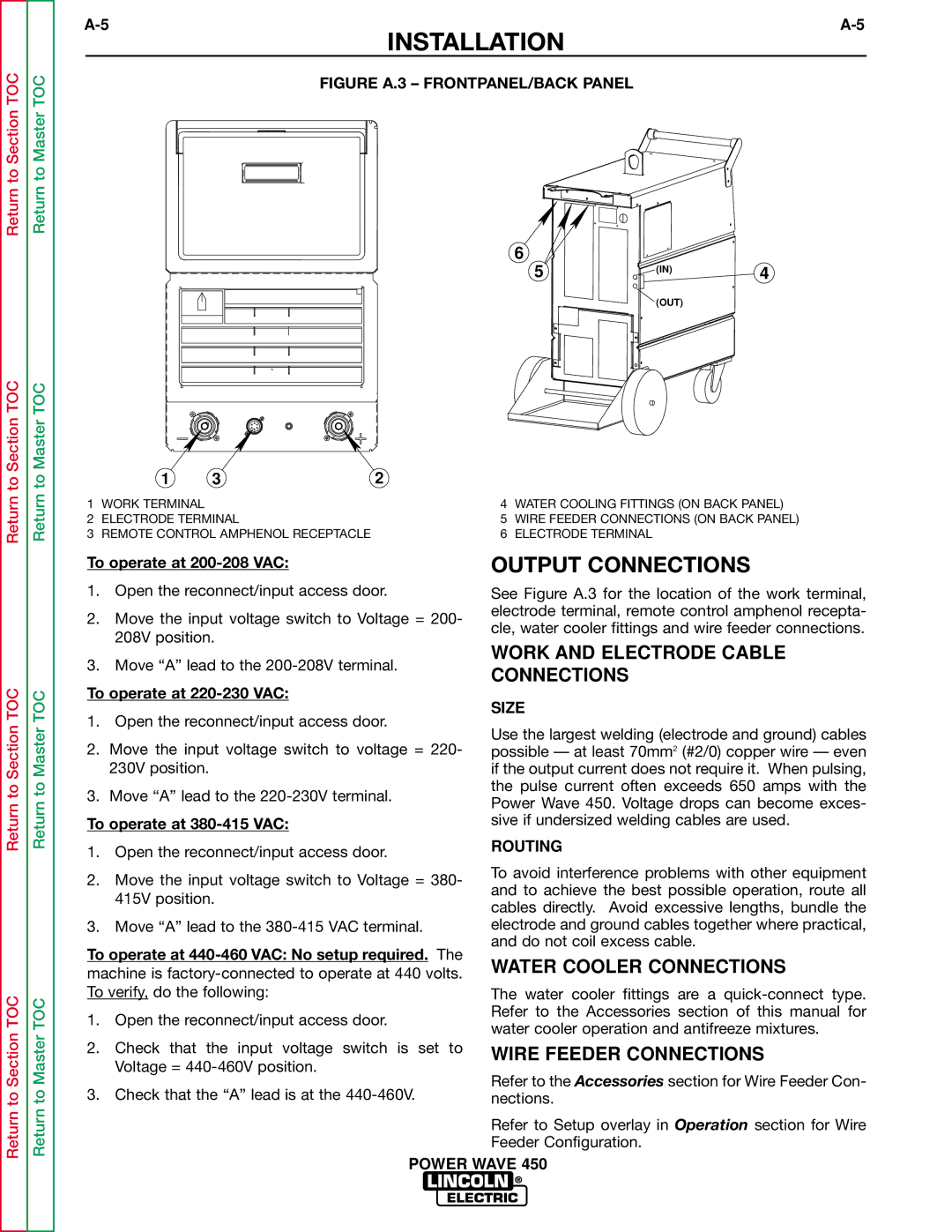

FIGURE A.3 – FRONTPANEL/BACK PANEL

6

54

(IN)

(OUT)

| 1 | 3 | 2 |

|

1 | WORK TERMINAL |

| 4 | WATER COOLING FITTINGS (ON BACK PANEL) |

2 | ELECTRODE TERMINAL | 5 | WIRE FEEDER CONNECTIONS (ON BACK PANEL) | |

3 | REMOTE CONTROL AMPHENOL RECEPTACLE | 6 | ELECTRODE TERMINAL | |

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

To operate at 200-208 VAC:

1.Open the reconnect/input access door.

2.Move the input voltage switch to Voltage = 200- 208V position.

3.Move “A” lead to the

To operate at 220-230 VAC:

1.Open the reconnect/input access door.

2.Move the input voltage switch to voltage = 220- 230V position.

3.Move “A” lead to the

To operate at 380-415 VAC:

1.Open the reconnect/input access door.

2.Move the input voltage switch to Voltage = 380- 415V position.

3.Move “A” lead to the

To operate at

1.Open the reconnect/input access door.

2.Check that the input voltage switch is set to Voltage =

3.Check that the “A” lead is at the

OUTPUT CONNECTIONS

See Figure A.3 for the location of the work terminal, electrode terminal, remote control amphenol recepta- cle, water cooler fittings and wire feeder connections.

WORK AND ELECTRODE CABLE CONNECTIONS

SIZE

Use the largest welding (electrode and ground) cables possible — at least 70mm2 (#2/0) copper wire — even if the output current does not require it. When pulsing, the pulse current often exceeds 650 amps with the Power Wave 450. Voltage drops can become exces- sive if undersized welding cables are used.

ROUTING

To avoid interference problems with other equipment and to achieve the best possible operation, route all cables directly. Avoid excessive lengths, bundle the electrode and ground cables together where practical, and do not coil excess cable.

WATER COOLER CONNECTIONS

The water cooler fittings are a

WIRE FEEDER CONNECTIONS

Refer to the Accessories section for Wire Feeder Con- nections.

Refer to Setup overlay in Operation section for Wire Feeder Configuration.

POWER WAVE 450