Master TOC

TROUBLESHOOTING & REPAIR

OUTPUT RECTIFIER BRIDGE REMOVAL AND REPLACEMENT (continued)

Return to

Return to Section TOC

Return to

Return to Master TOC

9.Cut all necessary cable ties on the right side of the machine and disconnect all necessary leads (two heavy and two small leads) from the right side of the output rectifier bridge. Place the fastener hard- ware back together onto the lead ends to avoid loss.

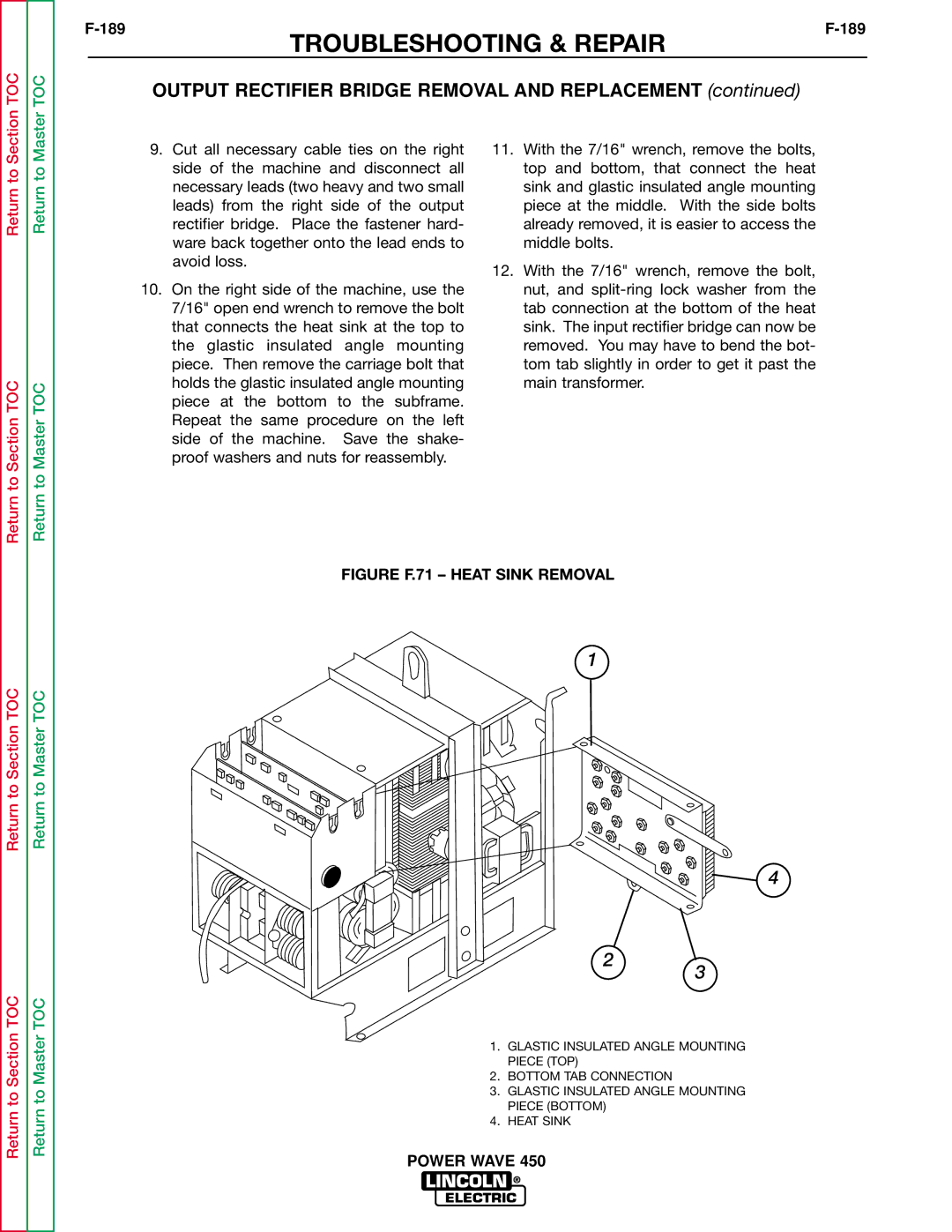

10.On the right side of the machine, use the 7/16" open end wrench to remove the bolt that connects the heat sink at the top to the glastic insulated angle mounting piece. Then remove the carriage bolt that holds the glastic insulated angle mounting piece at the bottom to the subframe. Repeat the same procedure on the left side of the machine. Save the shake- proof washers and nuts for reassembly.

11.With the 7/16" wrench, remove the bolts, top and bottom, that connect the heat sink and glastic insulated angle mounting piece at the middle. With the side bolts already removed, it is easier to access the middle bolts.

12.With the 7/16" wrench, remove the bolt, nut, and

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

FIGURE F.71 – HEAT SINK REMOVAL

1

4

2 3

1.GLASTIC INSULATED ANGLE MOUNTING PIECE (TOP)

2.BOTTOM TAB CONNECTION

3.GLASTIC INSULATED ANGLE MOUNTING PIECE (BOTTOM)

4.HEAT SINK