Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR

CURRENT CALIBRATION

WARNING

Service and repair should be performed by only Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. For your safety and to avoid elec- trical shock, please observe all safety notes and precautions detailed throughout this manual.

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical trou- bleshooting assistance before you proceed. Call

PROCEDURE DESCRIPTION

This procedure is necessary if the control and/or the shunt amplifier boards are replaced. The current control is the most critical function in the Power Wave machine.

MATERIALS NEEDED

Test and Calibration Overlay

A 300 amp, 30 volt resistance grid load

A small trimmer screwdriver

A calibrated DC ammeter accurate to read 300.0 amps +/- 1.0 amps.

A machine output triggering device such as the

SETUP PROCEDURE

1. Remove and install the replacement board in question.

This procedure takes approximately 45 minutes to perform.

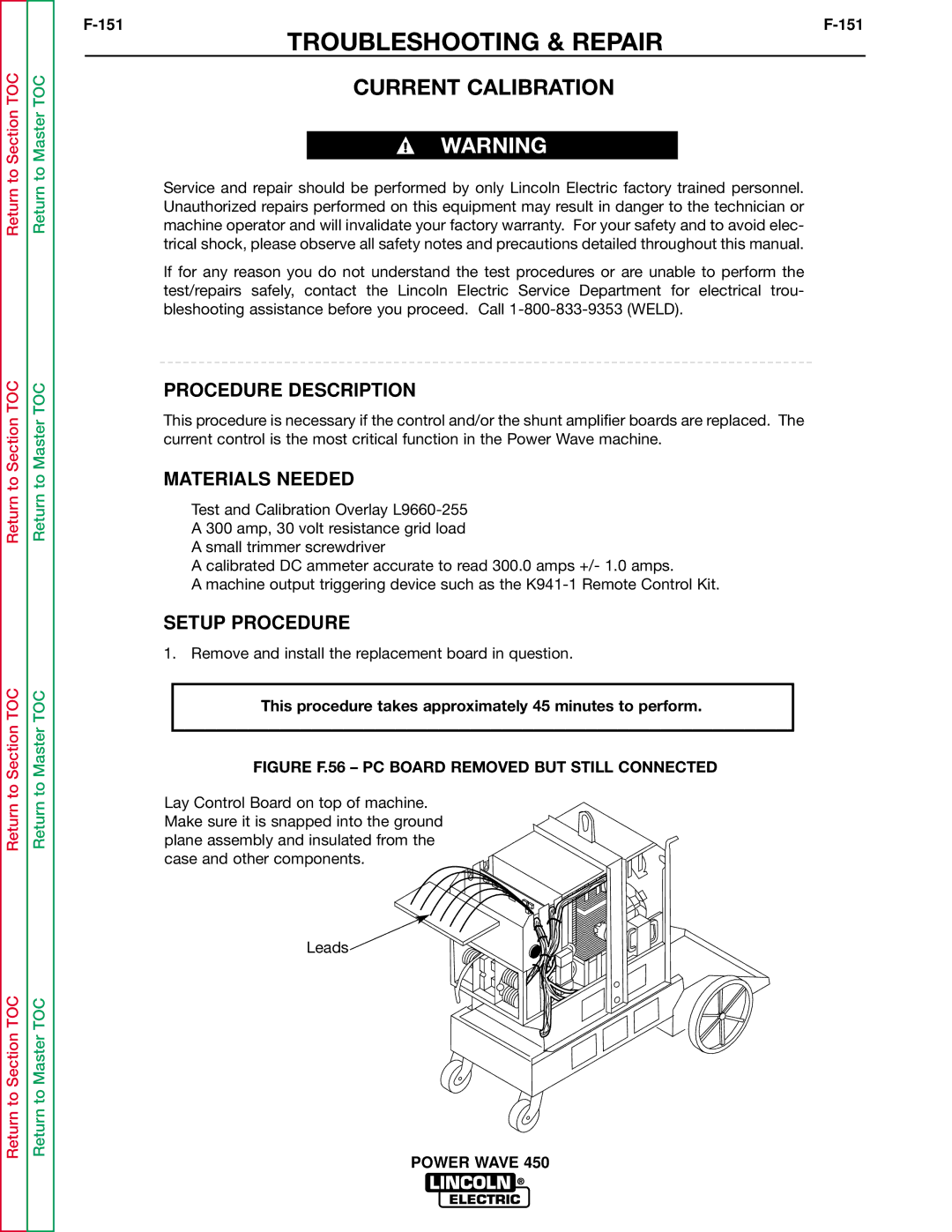

FIGURE F.56 – PC BOARD REMOVED BUT STILL CONNECTED

Lay Control Board on top of machine. Make sure it is snapped into the ground plane assembly and insulated from the case and other components.

Leads![]()