Return to Section TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR

INPUT RECTIFIER REMOVAL AND REPLACEMENT (continued)

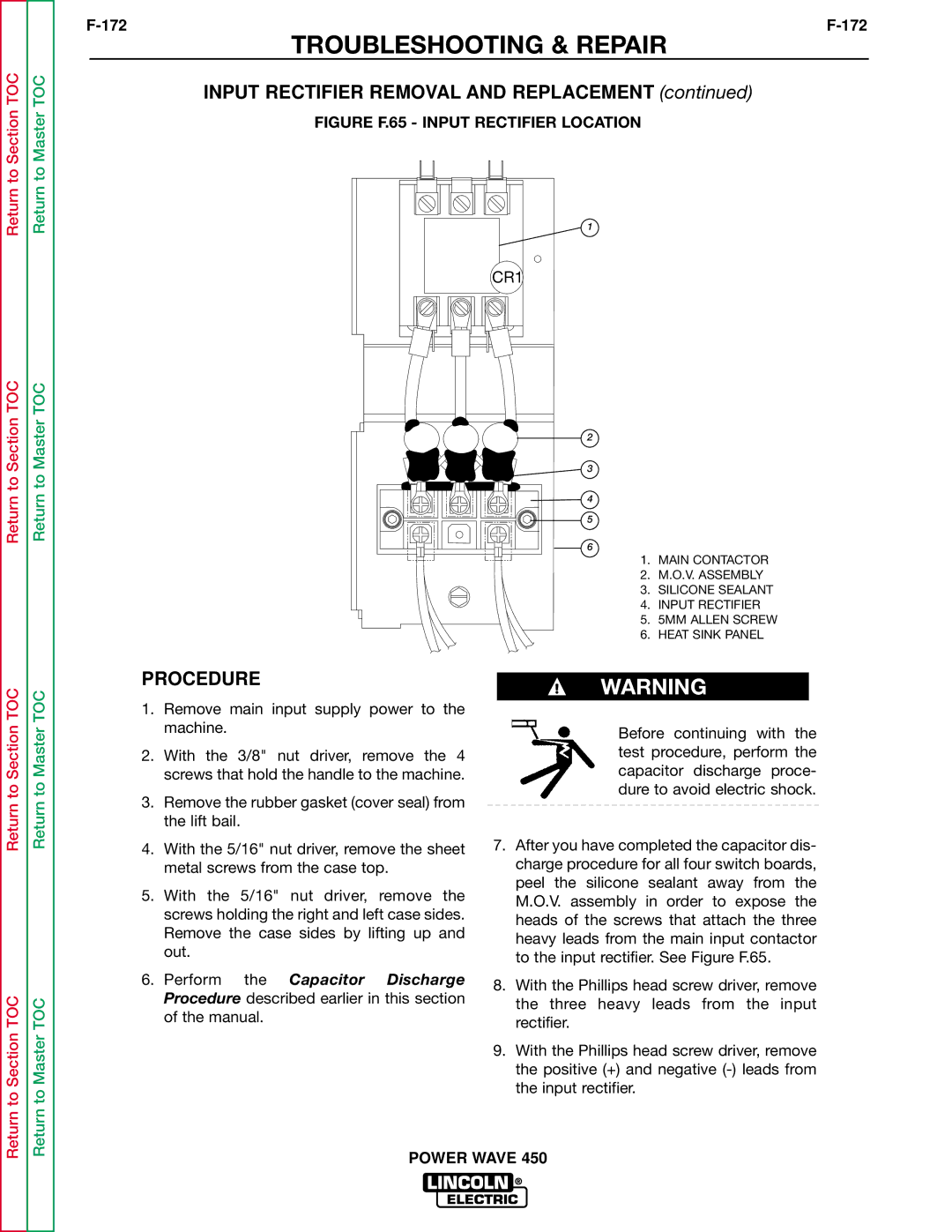

FIGURE F.65 - INPUT RECTIFIER LOCATION

1

CR1

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

PROCEDURE

1.Remove main input supply power to the machine.

2.With the 3/8" nut driver, remove the 4 screws that hold the handle to the machine.

3.Remove the rubber gasket (cover seal) from the lift bail.

4.With the 5/16" nut driver, remove the sheet metal screws from the case top.

5.With the 5/16" nut driver, remove the screws holding the right and left case sides. Remove the case sides by lifting up and out.

6.Perform the Capacitor Discharge Procedure described earlier in this section of the manual.

2

3

4 5

6

1.MAIN CONTACTOR

2.M.O.V. ASSEMBLY

3.SILICONE SEALANT

4.INPUT RECTIFIER

5.5MM ALLEN SCREW

6.HEAT SINK PANEL

WARNING

Before continuing with the test procedure, perform the capacitor discharge proce- dure to avoid electric shock.

7.After you have completed the capacitor dis- charge procedure for all four switch boards, peel the silicone sealant away from the M.O.V. assembly in order to expose the heads of the screws that attach the three heavy leads from the main input contactor to the input rectifier. See Figure F.65.

8.With the Phillips head screw driver, remove the three heavy leads from the input rectifier.

9.With the Phillips head screw driver, remove the positive (+) and negative