Return to Section TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR

FULL VOLTAGE CALIBRATION(continued)

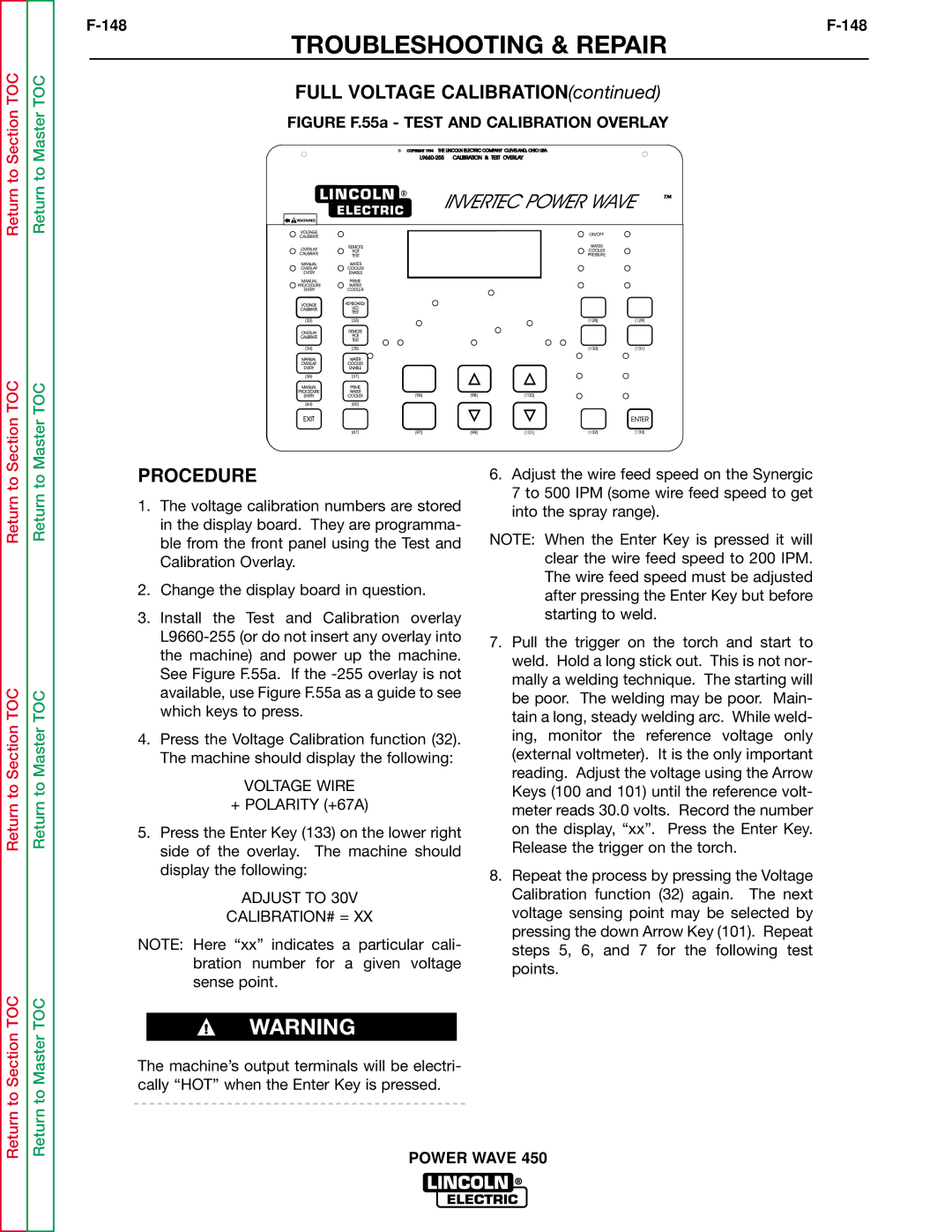

FIGURE F.55a - TEST AND CALIBRATION OVERLAY

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

PROCEDURE

1.The voltage calibration numbers are stored in the display board. They are programma- ble from the front panel using the Test and Calibration Overlay.

2.Change the display board in question.

3.Install the Test and Calibration overlay

4.Press the Voltage Calibration function (32). The machine should display the following:

VOLTAGE WIRE

+POLARITY (+67A)

5.Press the Enter Key (133) on the lower right side of the overlay. The machine should display the following:

ADJUST TO 30V

CALIBRATION# = XX

NOTE: Here “xx” indicates a particular cali- bration number for a given voltage sense point.

6.Adjust the wire feed speed on the Synergic 7 to 500 IPM (some wire feed speed to get into the spray range).

NOTE: When the Enter Key is pressed it will clear the wire feed speed to 200 IPM. The wire feed speed must be adjusted after pressing the Enter Key but before starting to weld.

7.Pull the trigger on the torch and start to weld. Hold a long stick out. This is not nor- mally a welding technique. The starting will be poor. The welding may be poor. Main- tain a long, steady welding arc. While weld- ing, monitor the reference voltage only (external voltmeter). It is the only important reading. Adjust the voltage using the Arrow Keys (100 and 101) until the reference volt- meter reads 30.0 volts. Record the number on the display, “xx”. Press the Enter Key. Release the trigger on the torch.

8.Repeat the process by pressing the Voltage Calibration function (32) again. The next voltage sensing point may be selected by pressing the down Arrow Key (101). Repeat steps 5, 6, and 7 for the following test points.

Return to Section TOC

Return to Master TOC

WARNING

The machine’s output terminals will be electri- cally “HOT” when the Enter Key is pressed.