ACCESSORIES

Return to Section TOC

There are two water connections on the rear of the Power Wave. See Figure C.1. Connect the water lines between these connectors and those on the wire feed- er. The water is fed through the feeder into the gun.

When a water cooler is used, the water cooler must be enabled by using the Setup Overlay.

The water cooler contains a flow switch, which is closed when there is adequate coolant circulating in the system. If this flow rate drops below the switch manufacturer’s set point, the flow switch opens. A cou- ple of seconds after the flow switch opens the water cooler shuts down. If the water cooler is enabled and the flow switch opens, the machine beeps loudly indi- cating that there is a problem with the water cooler operation.

a. Install the

b. Keep accessories’ hose lengths horizontal, either coiled or straight, and no higher than 4 feet of the specified coolant level.

c. Switch on the Power Wave machine.

d. Press the "WATER COOLER ENABLE" button so that the "WATER COOLER ENABLED" light is illuminated.

e. Press the "PRIME WATER COOLER" button until the "WATER COOLER PRESSURE" light is steadily illuminated.

4. Check coolant level. Add more if required.

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

RECOMMENDED COOLANTS

1.The following coolants have been determined to be compatible with the wetted materials used in the

•Distilled or deionized water

•Potable tap water

•

2.Ethylene glycol mixtures should be selected if the cooler may be exposed to a temperature below the freezing point of water.

3.Consult gun, torch, and wire feeder manuals for coolant recommendations and select one from the above list.

4.Pure solutions and mixtures of, or materials (i.e. towels) wetted with ethylene glycol are toxic to humans and animals. They must not be haphaz- ardly discarded, especially by pouring liquids down the drain. Contact the local EPA office for responsi- ble disposal methods or for recycling information.

5.The cooler’s reservoir has a nominal liquid capaci- ty of 1.6 gallons.

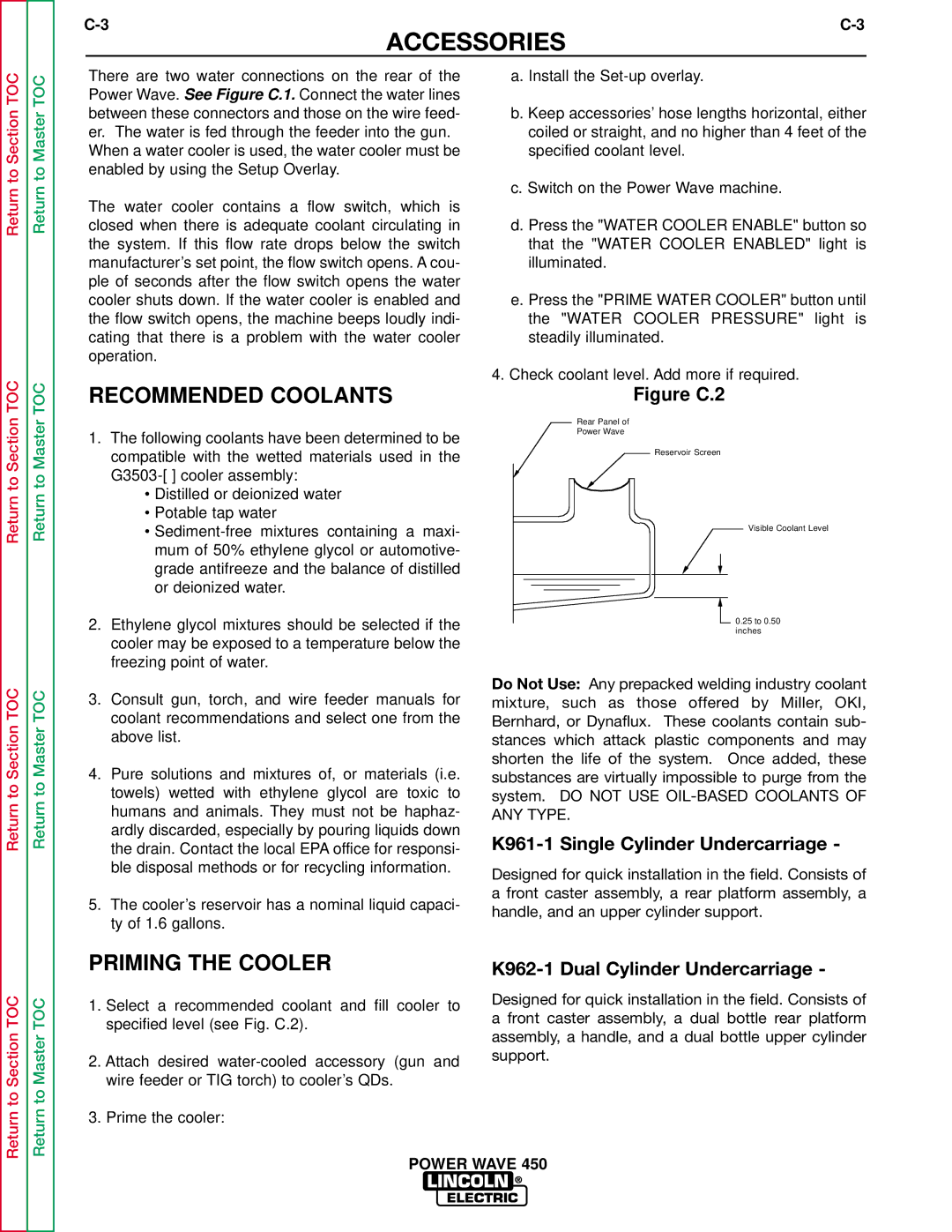

Figure C.2

Rear Panel of

Power Wave

Reservoir Screen

Visible Coolant Level

0.25 to 0.50 inches

Do Not Use: Any prepacked welding industry coolant mixture, such as those offered by Miller, OKI, Bernhard, or Dynaflux. These coolants contain sub- stances which attack plastic components and may shorten the life of the system. Once added, these substances are virtually impossible to purge from the system. DO NOT USE

Designed for quick installation in the field. Consists of a front caster assembly, a rear platform assembly, a handle, and an upper cylinder support.

Return to Section TOC

Return to Master TOC

PRIMING THE COOLER

1.Select a recommended coolant and fill cooler to specified level (see Fig. C.2).

2.Attach desired

3.Prime the cooler:

K962-1 Dual Cylinder Undercarriage -

Designed for quick installation in the field. Consists of a front caster assembly, a dual bottle rear platform assembly, a handle, and a dual bottle upper cylinder support.