to Section TOC

Return to Master TOC

|

| |||

| THEORY OF OPERATION |

| ||

|

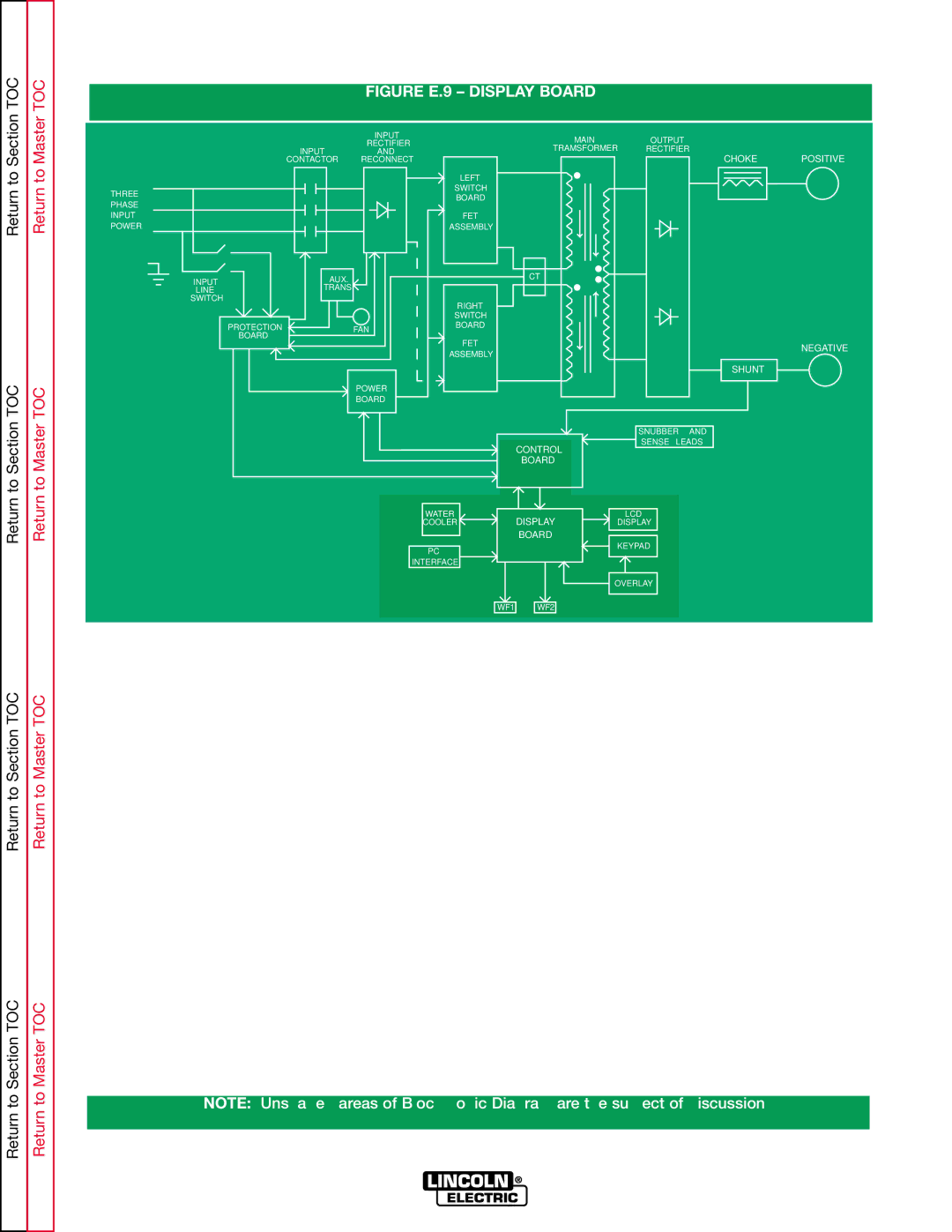

| FIGURE E.9 – DISPLAY BOARD |

| |

|

| INPUT | MAIN | OUTPUT |

|

| RECTIFIER | ||

|

| TRAMSFORMER | RECTIFIER | |

| INPUT | AND | ||

| CONTACTOR | RECONNECT |

| CHOKE POSITIVE |

|

|

| LEFT |

|

| THREE |

| SWITCH |

|

|

| BOARD |

| |

| PHASE |

|

| |

|

|

|

| |

Return

Return to Section TOC

Return to Master TOC

INPUT |

| FET |

POWER |

| ASSEMBLY |

INPUT | AUX. | CT |

TRANS |

| |

LINE |

| |

SWITCH |

| RIGHT |

|

| |

|

| SWITCH |

PROTECTION | FAN | BOARD |

BOARD |

| FET |

|

| |

|

| ASSEMBLY |

| POWER |

|

| BOARD |

|

CONTROL

BOARD

WATER

COOLERDISPLAY

BOARD

PC

INTERFACE

NEGATIVE

SHUNT

SNUBBER AND

SENSE LEADS

LCD

DISPLAY

KEYPAD

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

OVERLAY

WF1 WF2

DISPLAY BOARD

The Display Board allows the operator to select from the procedures that are programmed into the machine, and it lets the Control Board know which procedure was selected. These procedures are pro- grammed into the machine’s software package. The Display Board is used to communicate with the oper- ator. It determines what Overlay is installed in the machine and which buttons are active on the keypad. It also controls the LCD display, the lights on the front of the machine, the Piezo Buzzer and the water cool- er. Through the use of a current serial loop, the Display Board and Control Board communicate (or talk) to the wire feeder(s). The Display Board can also communicate with a computer through the RS232 interface.

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.