Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

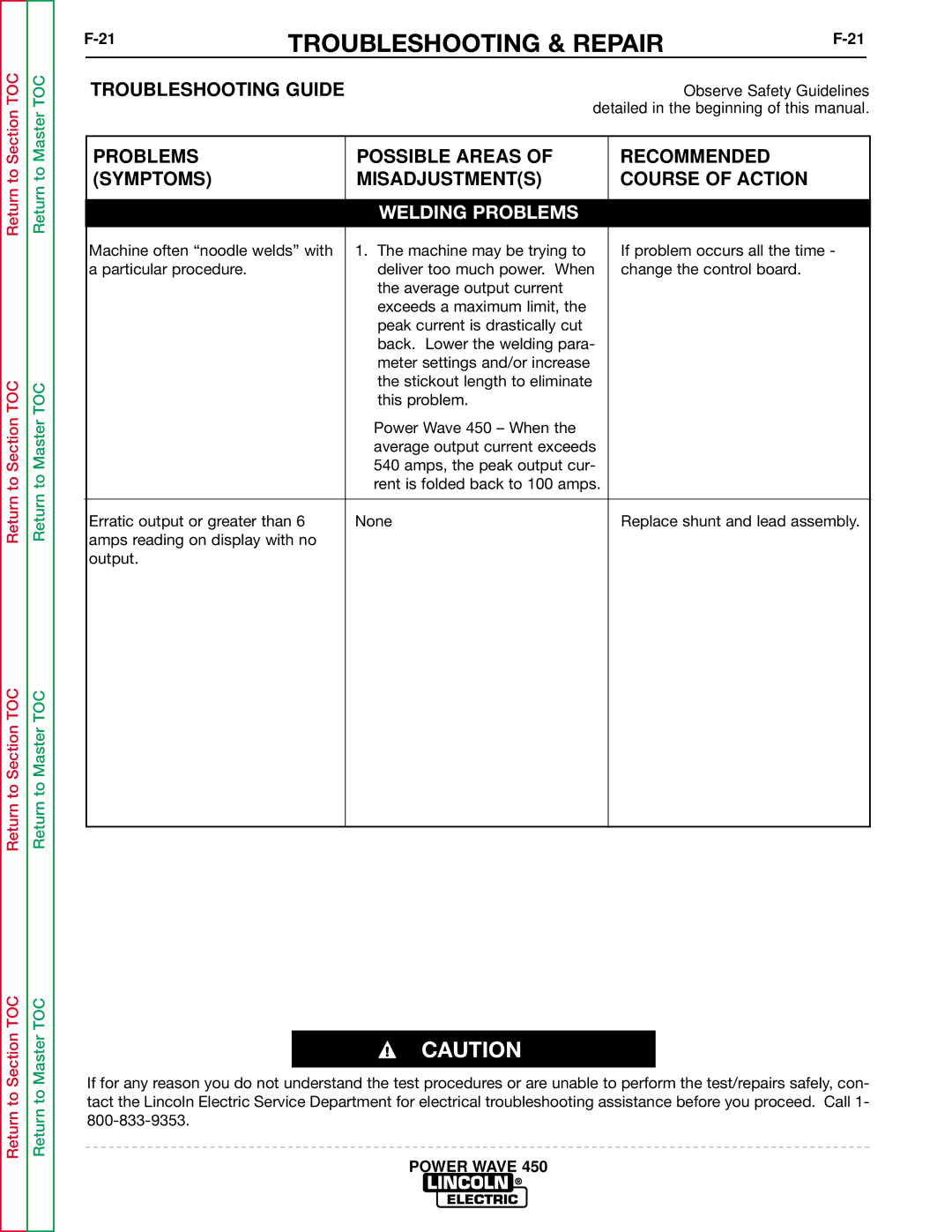

TROUBLESHOOTING & REPAIR | |||||

|

|

|

| ||

| TROUBLESHOOTING GUIDE |

| Observe Safety Guidelines | ||

|

|

| detailed in the beginning of this manual. | ||

| PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

| (SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION |

|

|

|

|

|

| WELDING PROBLEMS |

|

| Machine often “noodle welds” with | 1. The machine may be trying to | If problem occurs all the time - |

| a particular procedure. | deliver too much power. When | change the control board. |

|

| the average output current |

|

|

| exceeds a maximum limit, the |

|

|

| peak current is drastically cut |

|

|

| back. Lower the welding para- |

|

|

| meter settings and/or increase |

|

|

| the stickout length to eliminate |

|

|

| this problem. |

|

|

| Power Wave 450 – When the |

|

|

| average output current exceeds |

|

|

| 540 amps, the peak output cur- |

|

|

| rent is folded back to 100 amps. |

|

|

|

|

|

| Erratic output or greater than 6 | None | Replace shunt and lead assembly. |

| amps reading on display with no |

|

|

| output. |

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-